Method for producing wood-imitating plastic plate

A manufacturing method and board technology, applied in the field of manufacturing imitation wood plastic boards, can solve the problems of difficult fiber characteristics and texture, destruction of the earth's ecological environment, lack of real wood fiber texture, etc., and achieve the effect of improving toughness and good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

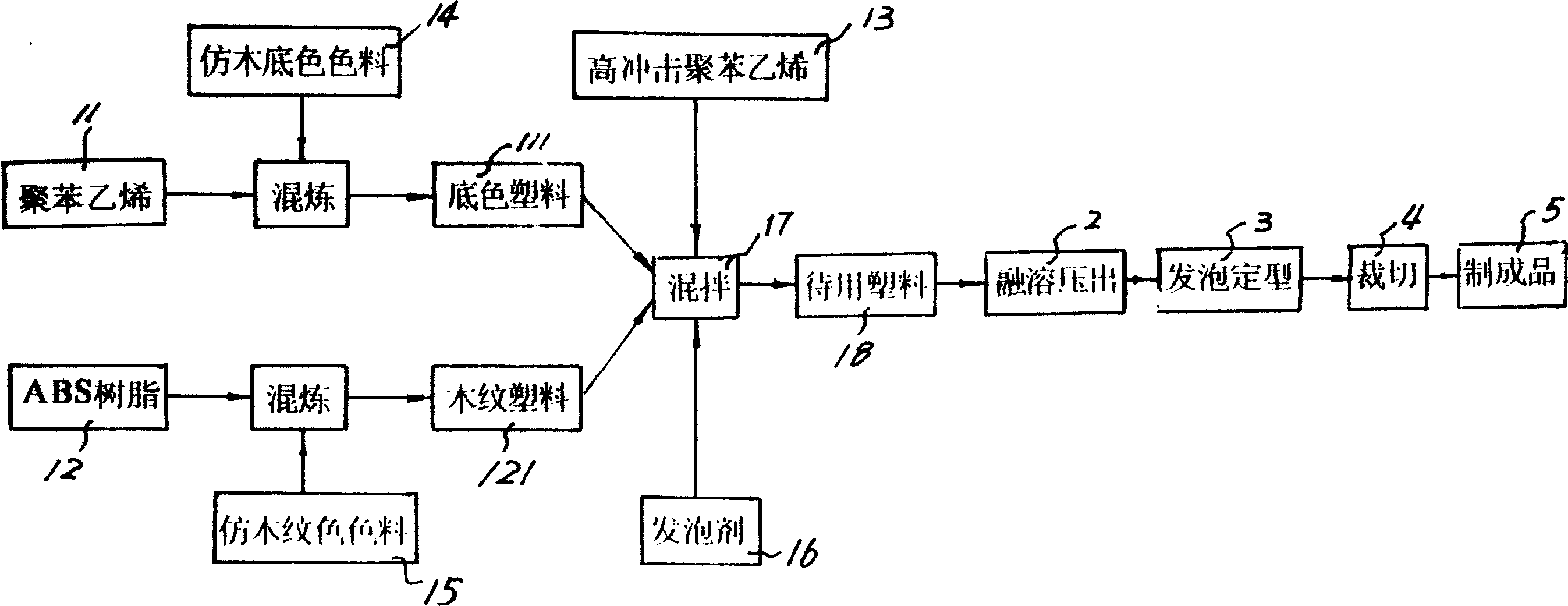

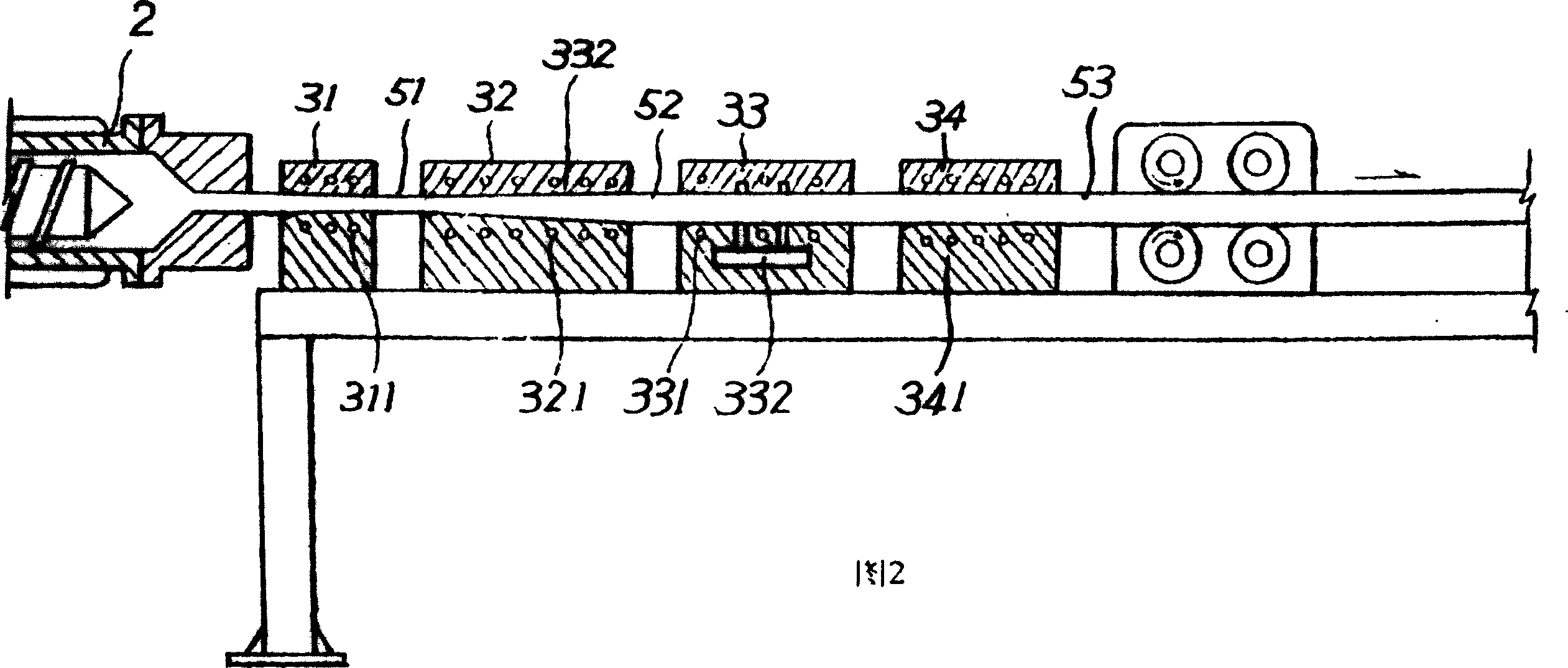

[0018] Describe in detail below in conjunction with accompanying drawing:

[0019] figure 1 , is the flowchart of the best embodiment of the manufacturing method of the present invention, as shown in the figure, the steps of this embodiment include material preparation step 1, melting step 2 and foaming and shaping step 3, and processes such as cutting steps 4; by weight ratio , the composition of this embodiment comprises the polystyrene 11 of 85%, the ABS resin 12 of 3% and the high-impact polystyrene 13 of 12%, and the trace foam-sweeping agent 16 and trace imitation wood base color pigment 14 and imitation The wood grain color pigment 15, wherein, the foaming starting point of the foaming agent 16 is 80-90°C; the melting temperature of the ABS resin 12 is higher than that of the polystyrene 11.

[0020] Material preparation step 1:

[0021] Mix hydrocarbons and resin materials, among which polystyrene 11 and high-impact polystyrene 13 are selected for hydrocarbon materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com