Manifold incorporating thermoelectric module and cooling device using thermoelectric module

A modular and thermoelectric technology, applied in the field of manifolds, can solve the problems of difficult Peltier elements stacked into multiple layers, difficult positioning operations, difficult manufacturing, etc., to achieve miniaturization of the shape, reduction of the number of components, and heat exchange The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

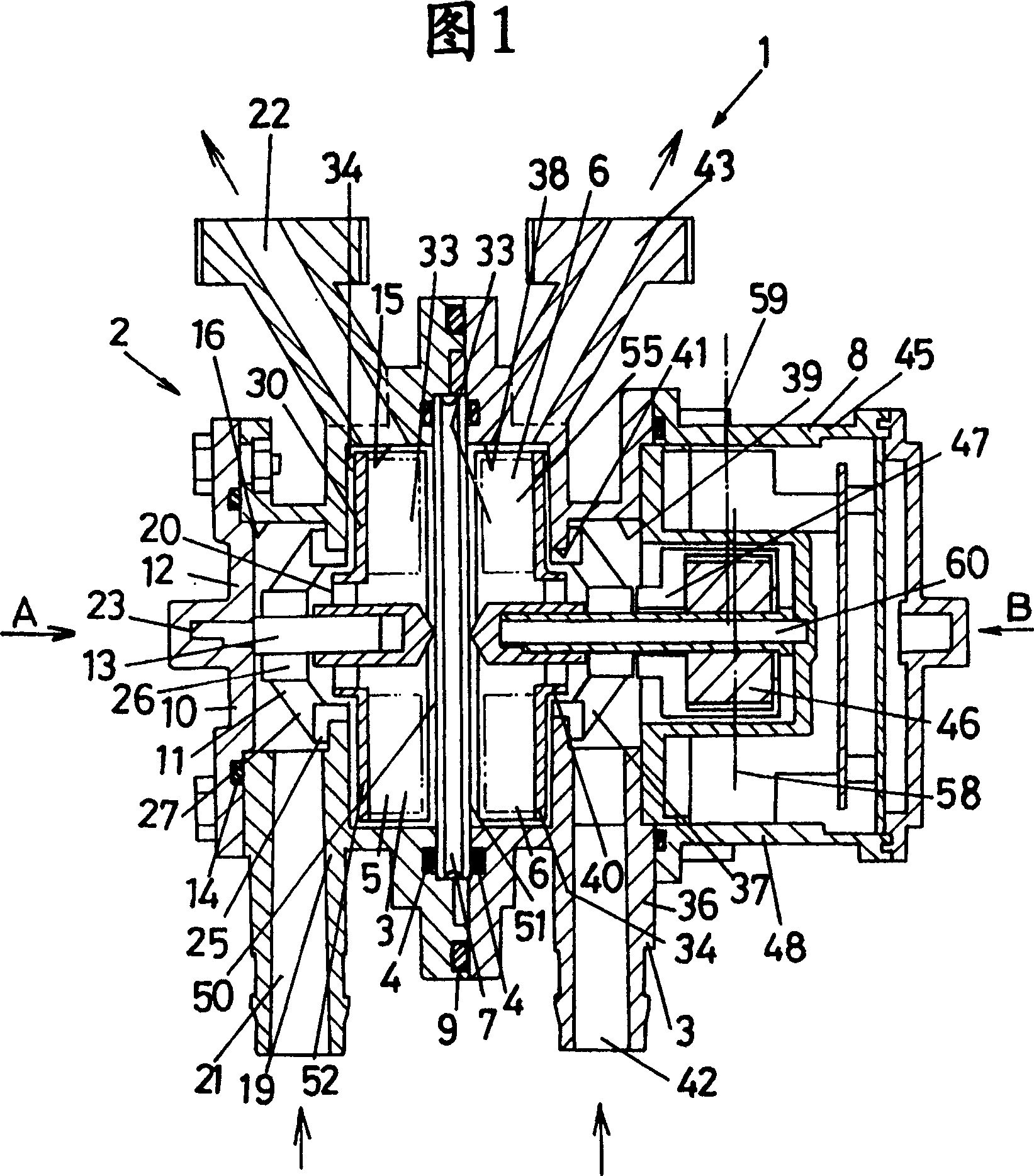

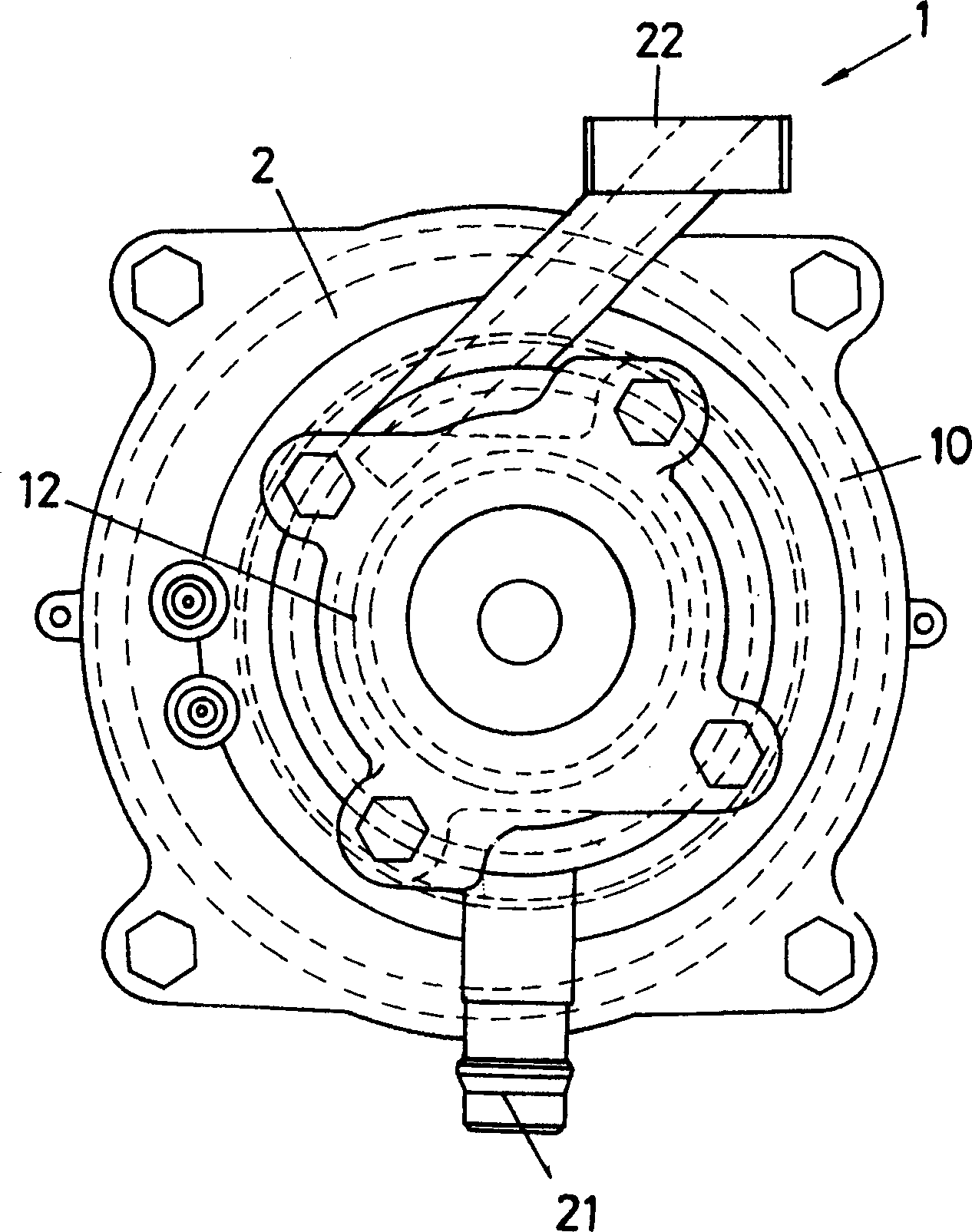

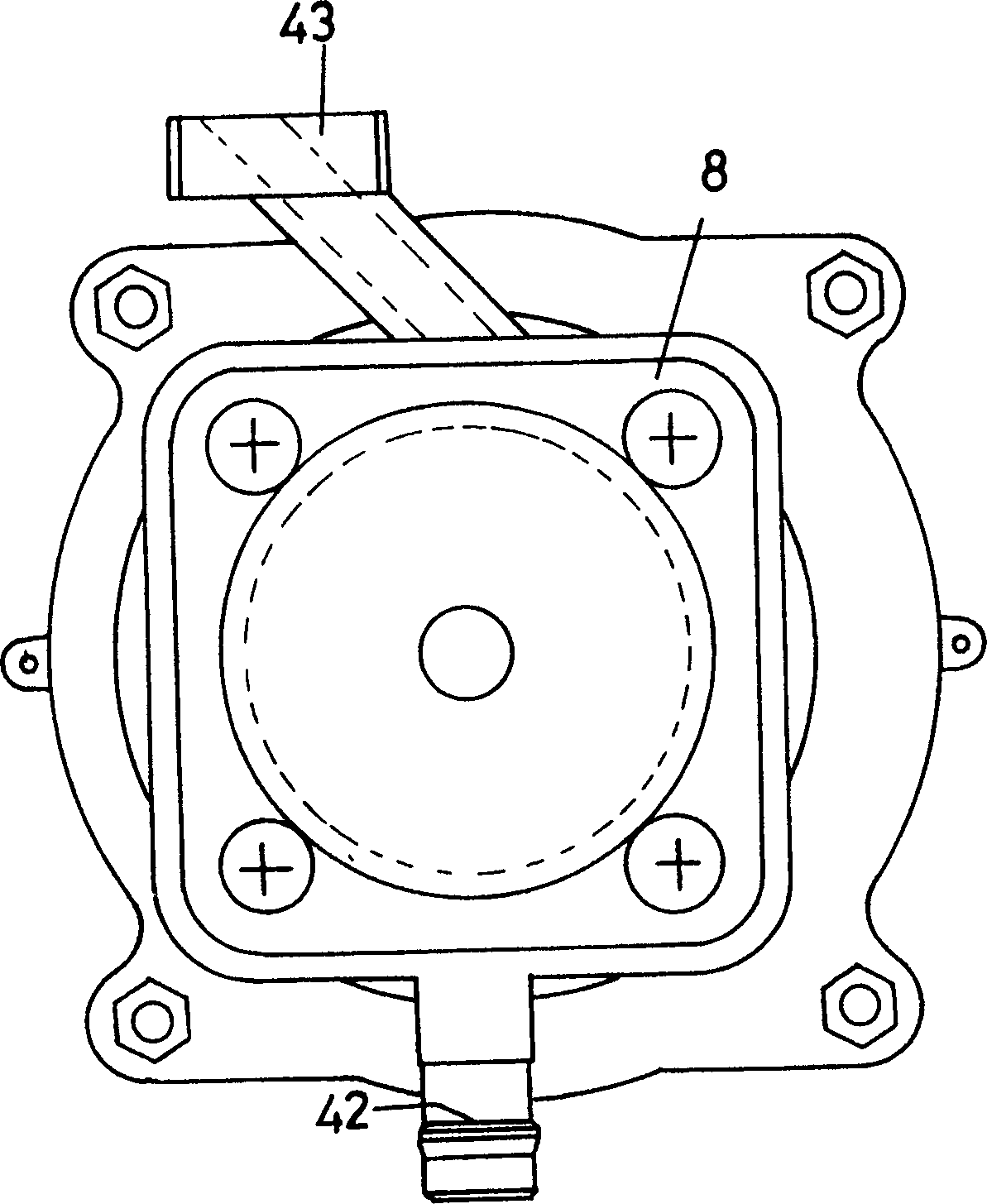

[0088] Refer to Figure 1 to Figure 9 The first embodiment of the present invention will be described.

[0089] Figure 1 to Figure 9Among them, 1 is a manifold with built-in thermoelectric modules representing an embodiment of the present invention. The manifold 1 is roughly composed of the cooling-side manifold piece 2 , the heating-side manifold piece 3 , the cooling-side stirring member 5 , the heating-side stirring member 6 , the thermoelectric module 7 and the motor member 8 .

[0090] The cooling side manifold 2 is composed of a manifold body 10 , a final shaft member 11 , a cover member 12 , a shaft 13 and a seal member 14 as shown in FIGS. 1 and 4 . The outer shape of the manifold body 10 is made to have a disk-shaped portion and a hub portion.

[0091] Regarding the internal structure of the manifold body 10, a circular recess 15 is provided at a disk-shaped portion. The hub portion is also provided with a circular recess 16 . In addition, a hole 20 is provided ...

Embodiment 2

[0133] Next, a second embodiment of the present invention will be described. In the description of the second and subsequent embodiments described below, members that can perform the same functions as those of the first embodiment are assigned the same symbols, and repeated descriptions thereof are omitted.

[0134] Figure 10 It is a front sectional view of a manifold with built-in thermoelectric modules according to the second embodiment of the present invention.

[0135] The manifold 70 with built-in thermoelectric modules of this embodiment, like the previous embodiment, can transmit the rotational force of the stirring member 71 on the heating side to the stirring member 72 on the cooling side by magnetic force, but the installation position of the magnet 73 is the same as that of the previous example. different.

[0136] That is to say, in the manifold 70 of this embodiment, the areas of the cavities 74 and 75 are larger than the area of the thermoelectric module 7 ....

Embodiment 3

[0139] Next, a third embodiment of the present invention will be described. Fig. 11 is a front sectional view of a manifold incorporating a thermoelectric module according to a third embodiment of the present invention.

[0140] Both of the above-described embodiments have a structure in which power is transmitted between the stirring members 5 and 6 by means of magnetic force, but in this embodiment, power is transmitted between the two by means of a shaft 78 .

[0141] That is, in the manifold 80 with built-in thermoelectric modules shown in FIG. Thus, the rotating shaft 78 is combined with the stirring member 5 on the cooling side. Thereby, the stirring member 6 on the heating side and the stirring member 5 on the cooling side are directly rotated by the rotation of the rotor 46 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com