Hydraulic coal mining method without underground drilling

A coal mining method and hydraulic technology, applied in the direction of earth drilling, underground mining, mining fluid, etc., can solve problems such as gas explosion, roof fall or water seepage, and achieve the effect of ensuring life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The unmanned downhole drilling hydraulic coal mining method is divided into: single well cavity expansion pre-mining stage and inclined hole connected long-distance mining stage.

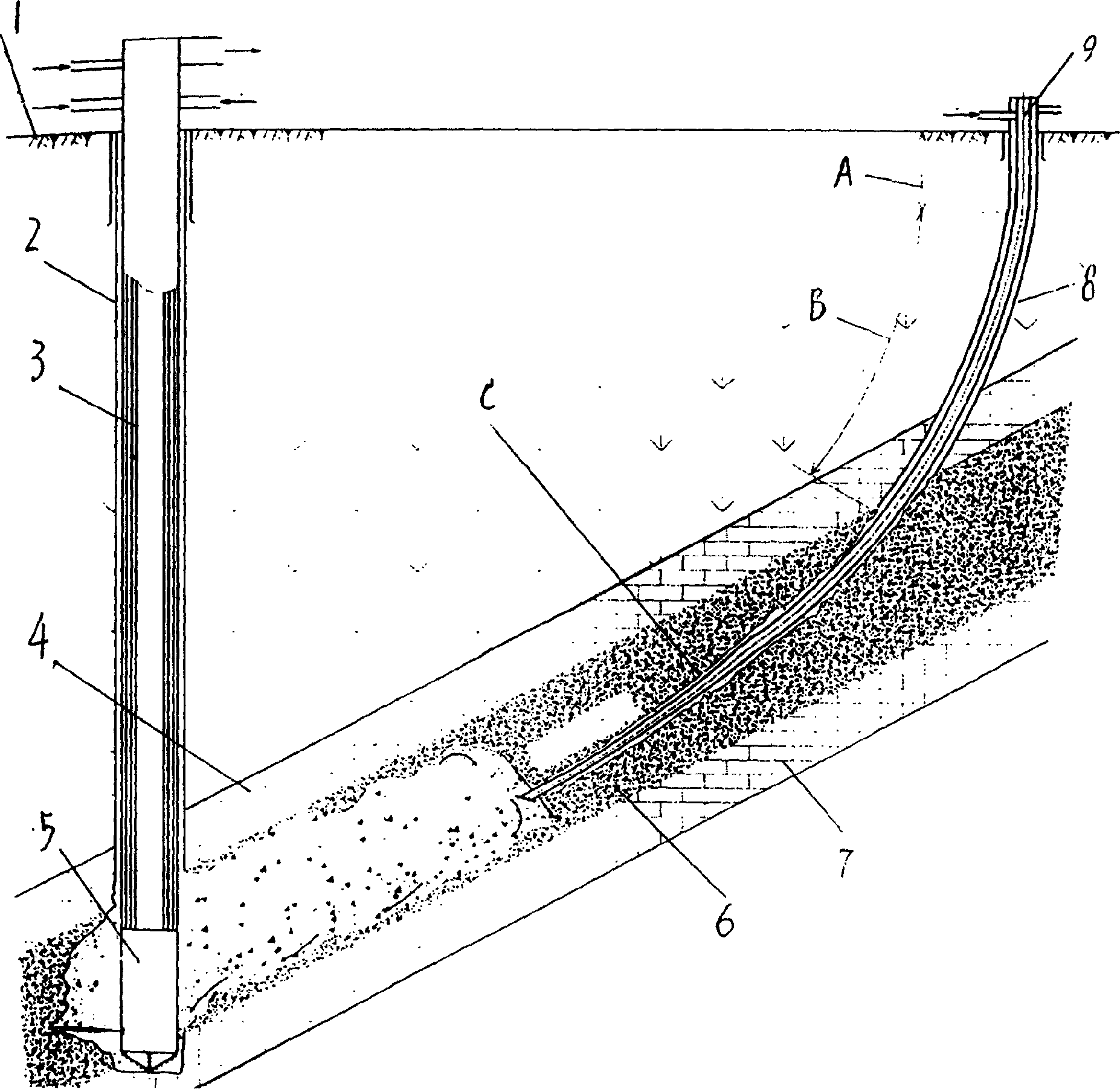

[0028] 1. The pre-exploitation stage of single well cavity expansion, see figure 1 .

[0029] 1. Vertical well drilling and completion.

[0030] The vertical shaft is also called the vertical shaft. Its drilling depth is 2 meters below the floor of the coal seam 6 to be mined, and the mining pipe string 3 is lowered to the roof 4 of the coal seam. It can be reused after mining.

[0031] 2. Run into the production string and production equipment.

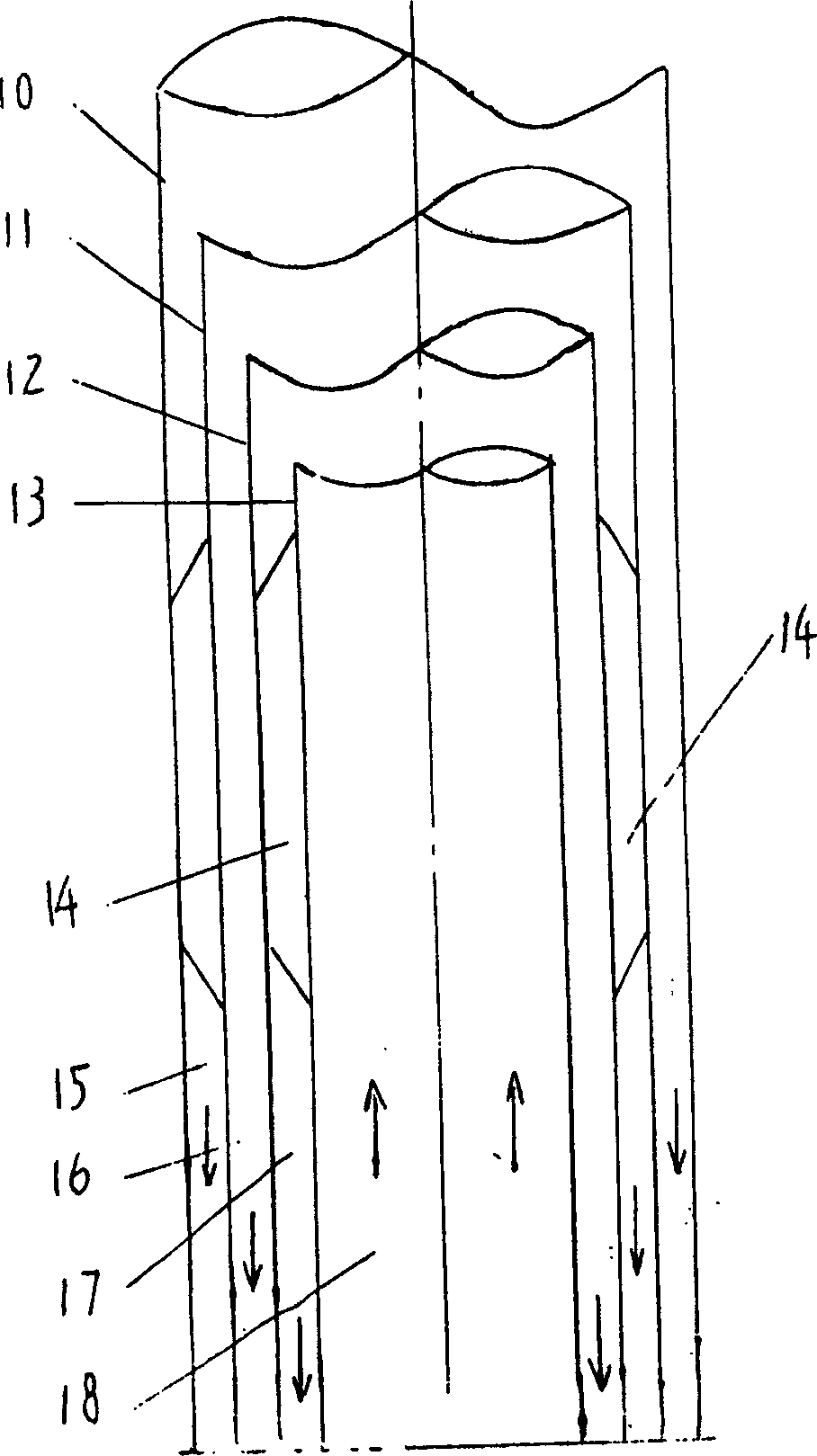

[0032] Production string 3 is made up of four layers of pipes 10, 11, 12, 13, see figure 2 , the four-layer tubes form four independent channels 15, 16, 17, and 18. Channels 15 and 16 are respectively injected with high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com