Energy saving multipurpose pump

A pump body and nozzle technology, applied in the field of multi-purpose pumps, can solve the problems of unsuitable use of pumps, high use cost, large energy waste, etc., and achieve the effects of low use cost, low friction resistance, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

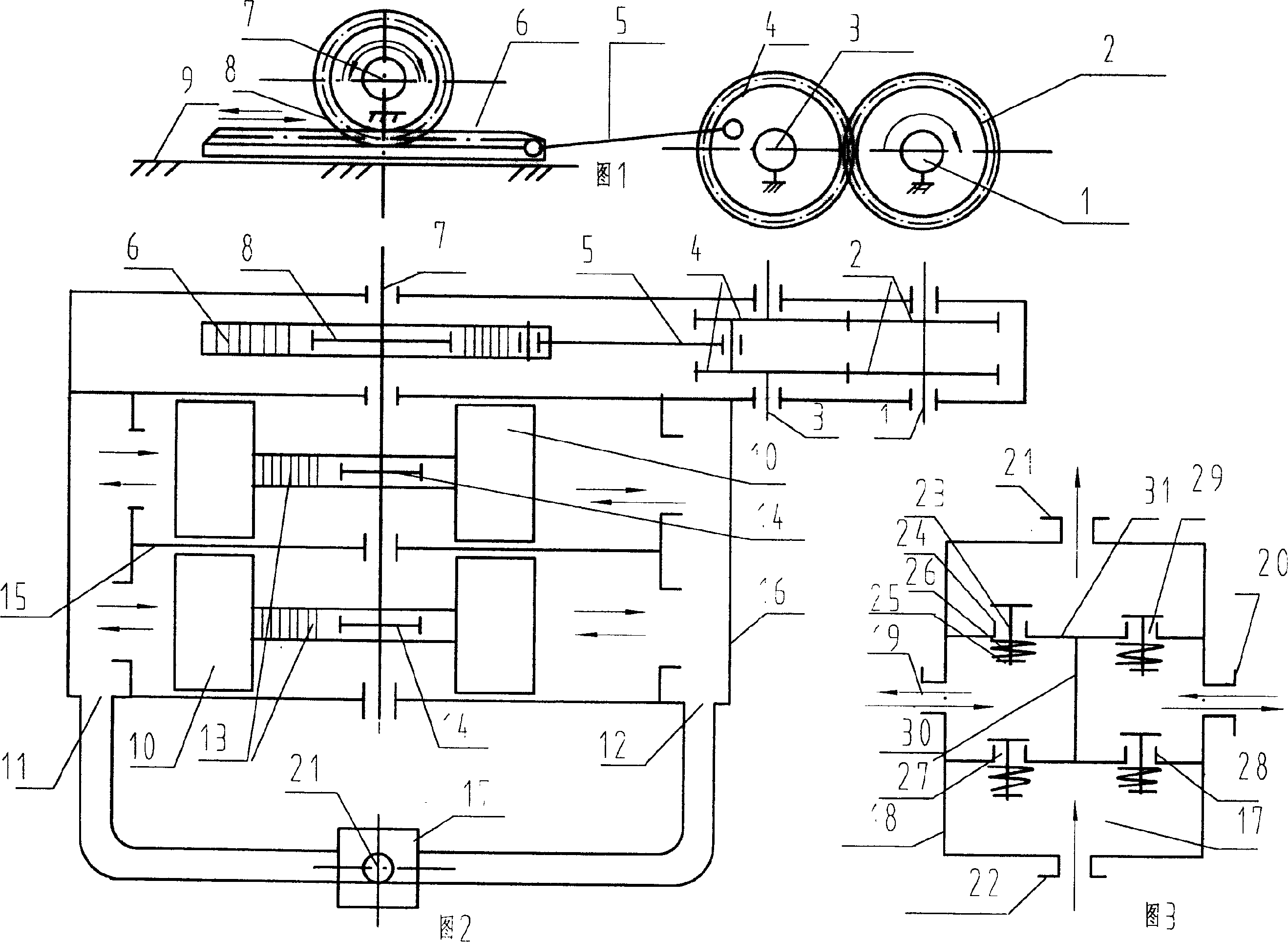

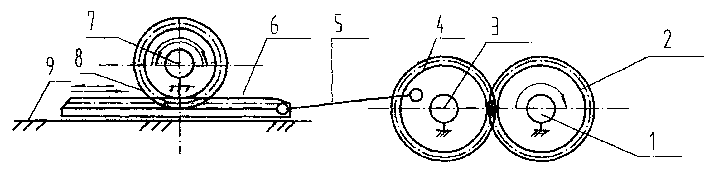

[0014] Referring to Figure 1-3, the multi-purpose pump consists of three parts: the driving device, the pump, and the one-way valve group.

[0015] The driving device is driven by a drive shaft 1, which can be driven by a low-speed motor, a hydraulic motor, a water power machine, etc., and a driving gear 2 is fixed on the drive shaft 1, and the driving gear 2 is in phase with the driven gear 4 fixed on the driven shaft 3. meshing, the main and driven gears 2 and 4 are duplex gears, the driven gear 4 is hinged with a connecting rod 5 through a pin shaft, and the connecting rod 5 is hinged with the rack 6 set on the slideway 9 through a pin shaft, The bar 6 meshes with a gear 8 fixed on the main shaft 7 .

[0016] The pump consists of a pump body 16, in which several groups of two-way pistons 10 separated by partitions 15 are built in the pump body 16. In this embodiment, there are two groups. The piston rod of the two-way piston 10 is a rack 13, which is fixed on the main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com