Projection tube

A projection tube and projection technology, applied in the field of projection tubes, can solve problems such as increased light spot size, poor definition, and impact on projection effects, and achieve the effects of enhanced pre-focusing, improved voltage resistance, and reduced amplification factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Accompanying drawing is the specific embodiment of the present invention.

[0019] The content of the present invention will be further described below in conjunction with the accompanying drawings.

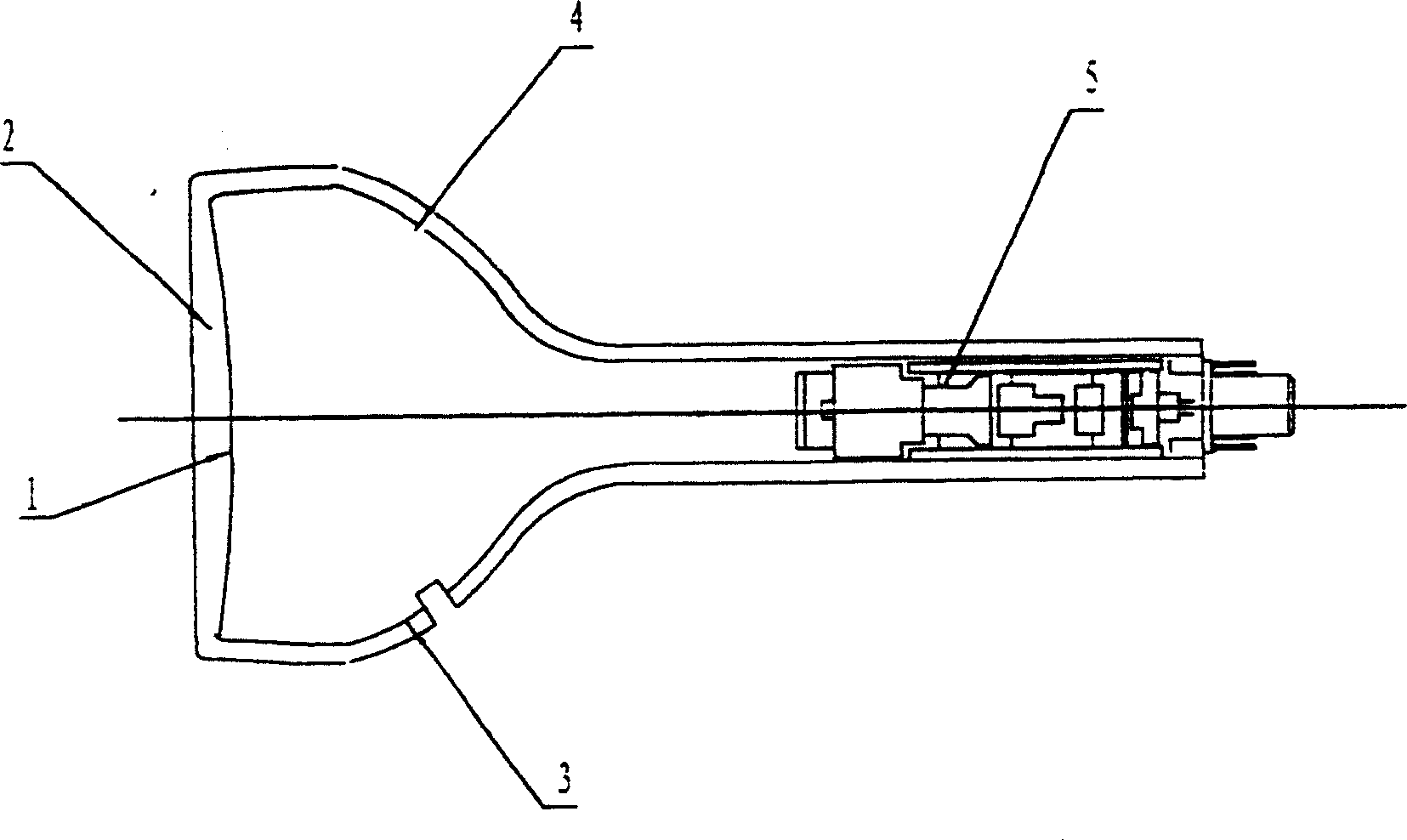

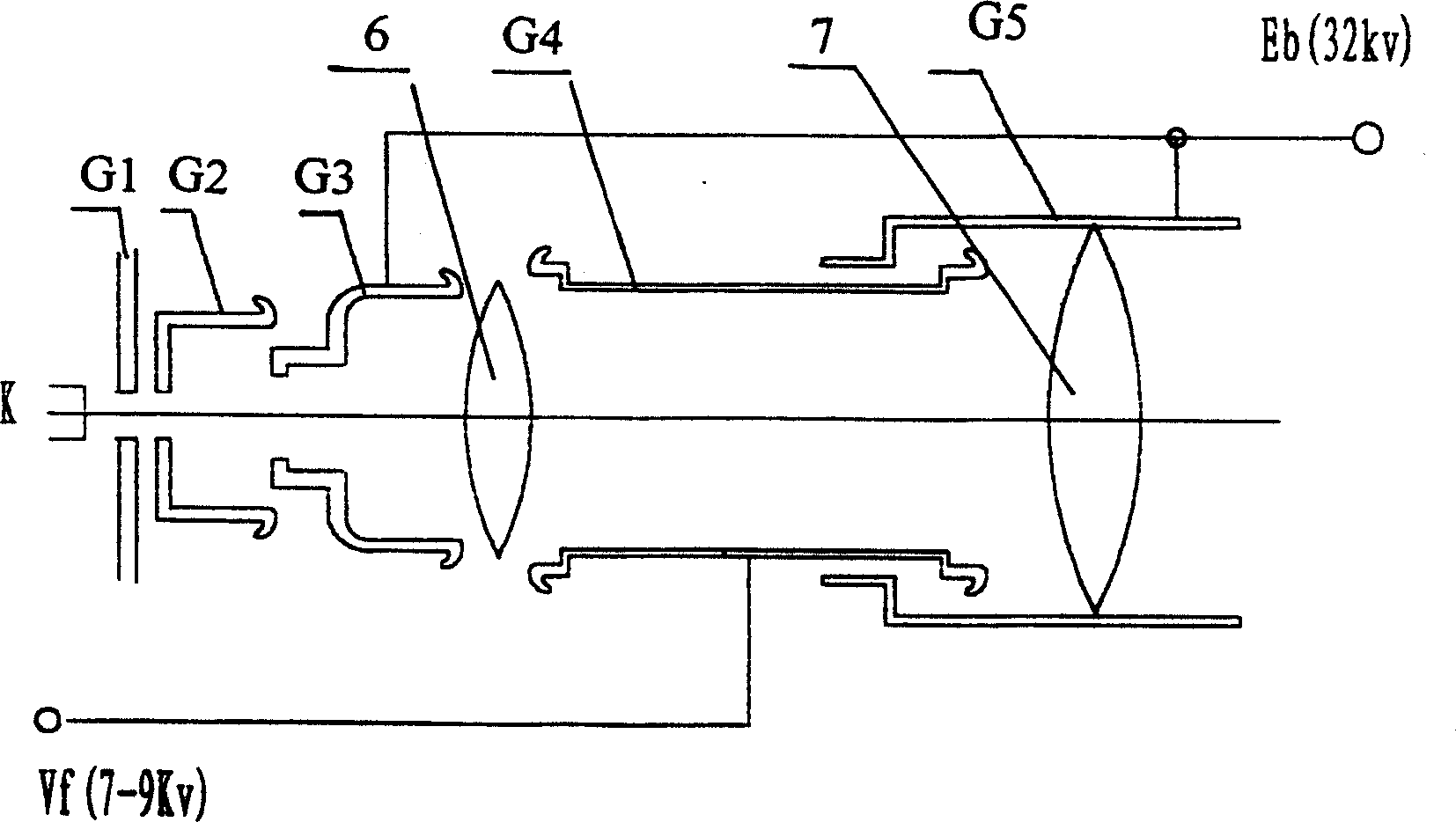

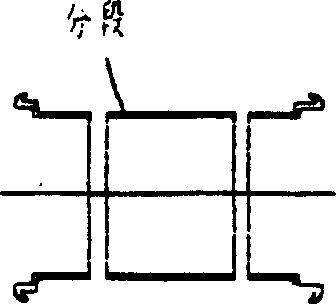

[0020] refer to figure 1 , 2 As shown, phosphor film 1 is coated on the negative curved screen of glass bulb 2, graphite layer 3 is coated on the neck of the projection tube, aluminum film 4 is coated in the tube, and electron gun 5 is installed at the tail of the cone. Said electron gun 5 is also Including the modulating electrode G1, the cathode K is placed in front of the modulating electrode G1, the accelerating electrode G2 is arranged behind the modulating electrode G1, the first anode electrode G3 is arranged behind the accelerating electrode G2, and the focusing electrode G4 is arranged behind the first anode electrode G3 , the second anode electrode G5 is set behind the focus electrode G4, and the ports of the acceleration electrode G2, the first anode electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com