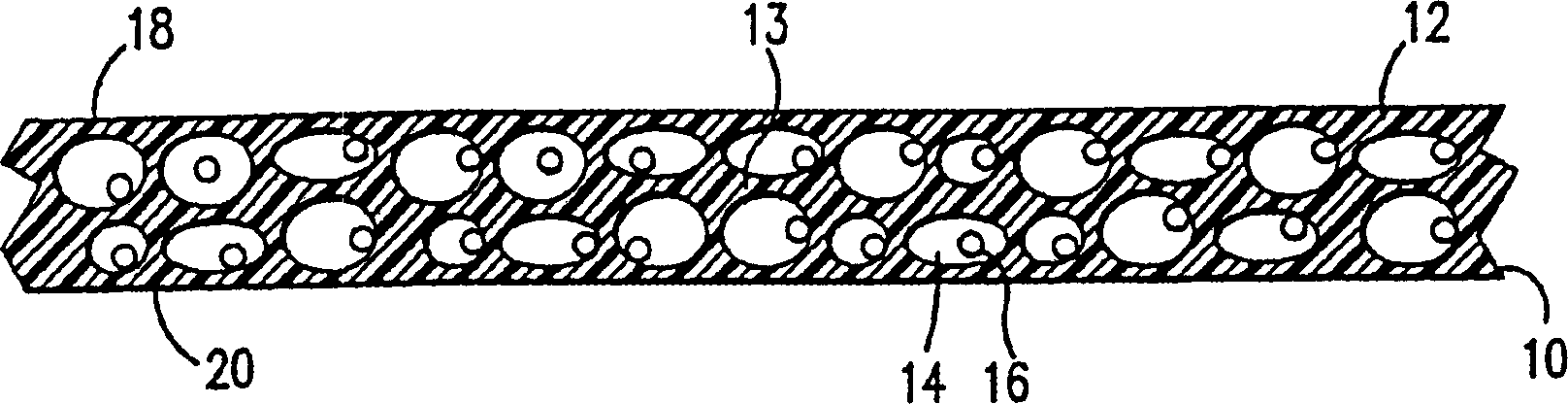

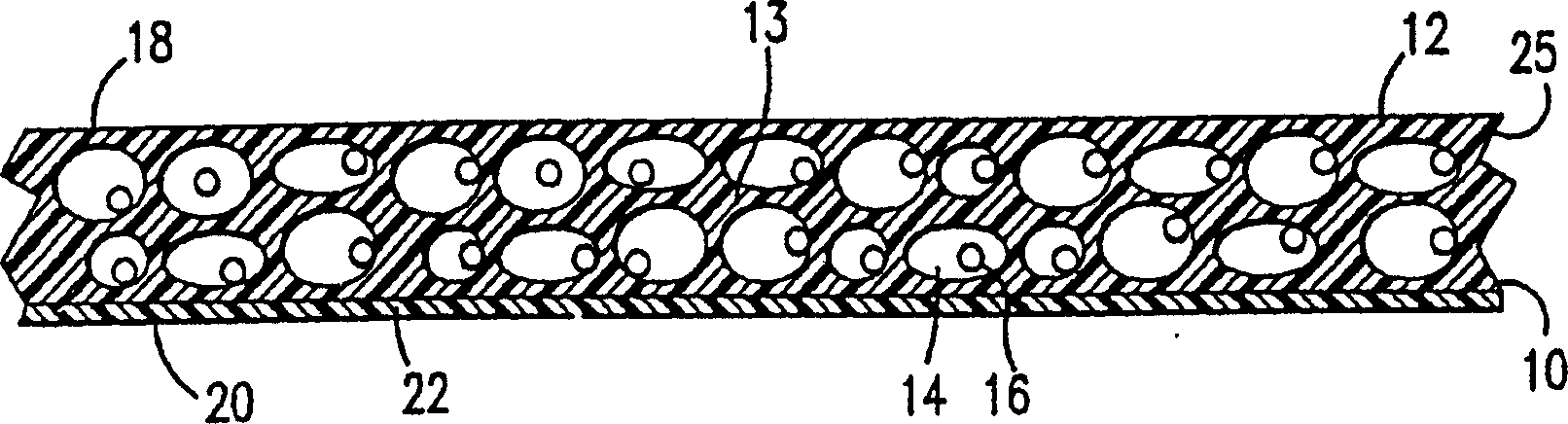

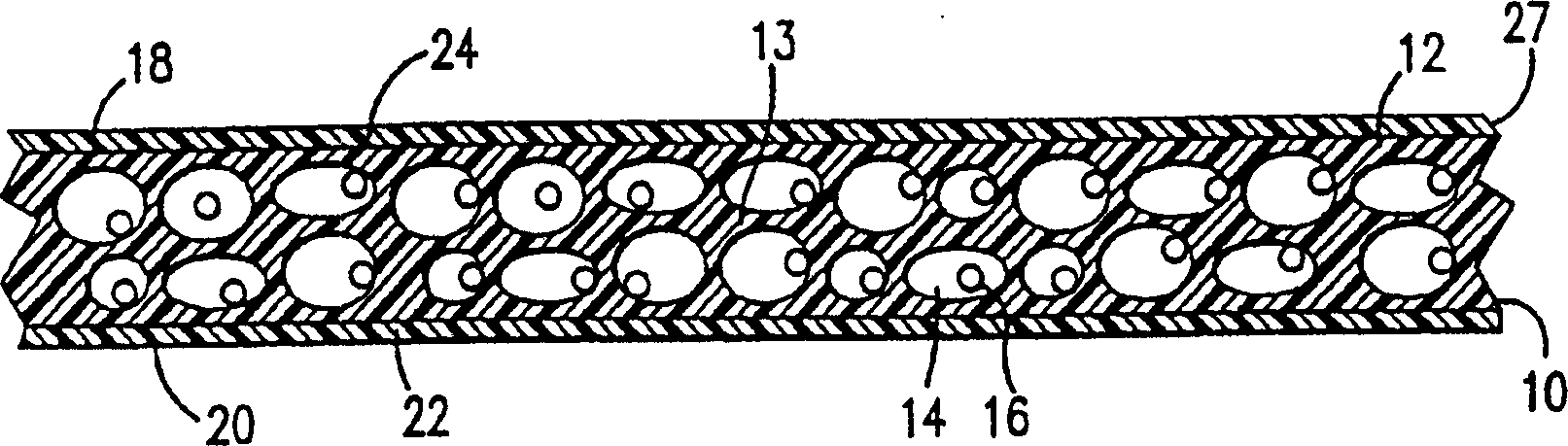

Breathable films and process for producing them

A breathable film and film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as insufficient strength to be used alone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0074] According to 6 kinds of filling polymer formulations, they were compounded and made into films on a film blowing line, and then uniaxially stretched using a longitudinal orienter. The obtained membranes were tested for WVTR using the procedure given above, and the hydraulic head pressure (resistance to hydraulic pressure) was also measured for some samples. Some also had tensile strength determined using the procedure described above. The following polymers were used in the formulation:

[0075] A.Exxon ICP PD-7623 E7, an impact copolymer containing 91wt% propylene and 9wt% ethylene, has a melt flow rate (230°C) of 7-10g / 10min; density, 0.90g / cc; crystallinity approx. 45%. The copolymer contains linear propylene segments and ethylene-propylene rubber segments.

[0076] B. Union Carbide 6D82, a propylene-ethylene random copolymer comprising 94.5 wt% propylene and 5.5 wt% ethylene with a melt flow rate (230°C) of 7 g / 10 min.

[0077] C. Dow NG3310, a linear low densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com