Mechanical vision fruit classifying system controlled by shift register

A shift register, fruit grading technology, applied in instruments, sorting, computer parts, etc., can solve the problems of easily damaged fruit surface, hindering the development of national economy and increasing farmers' income, affecting the value of fruit commodities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

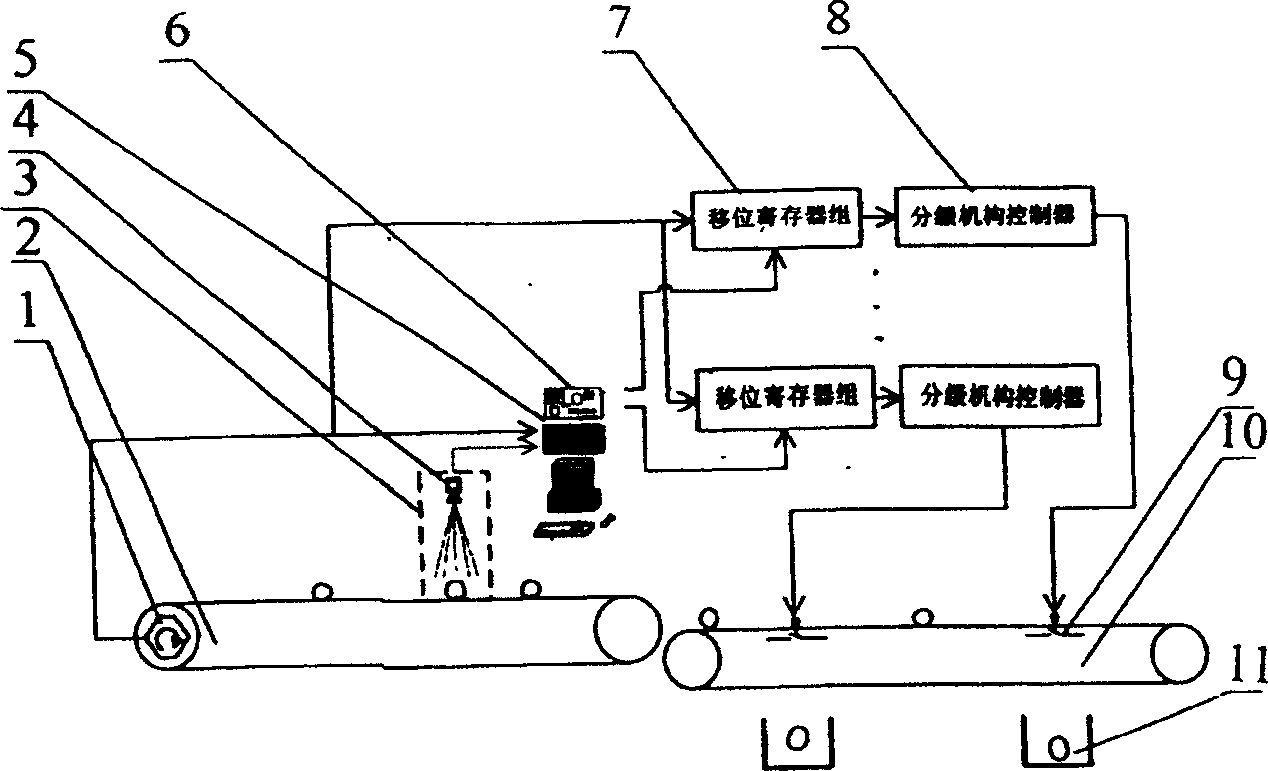

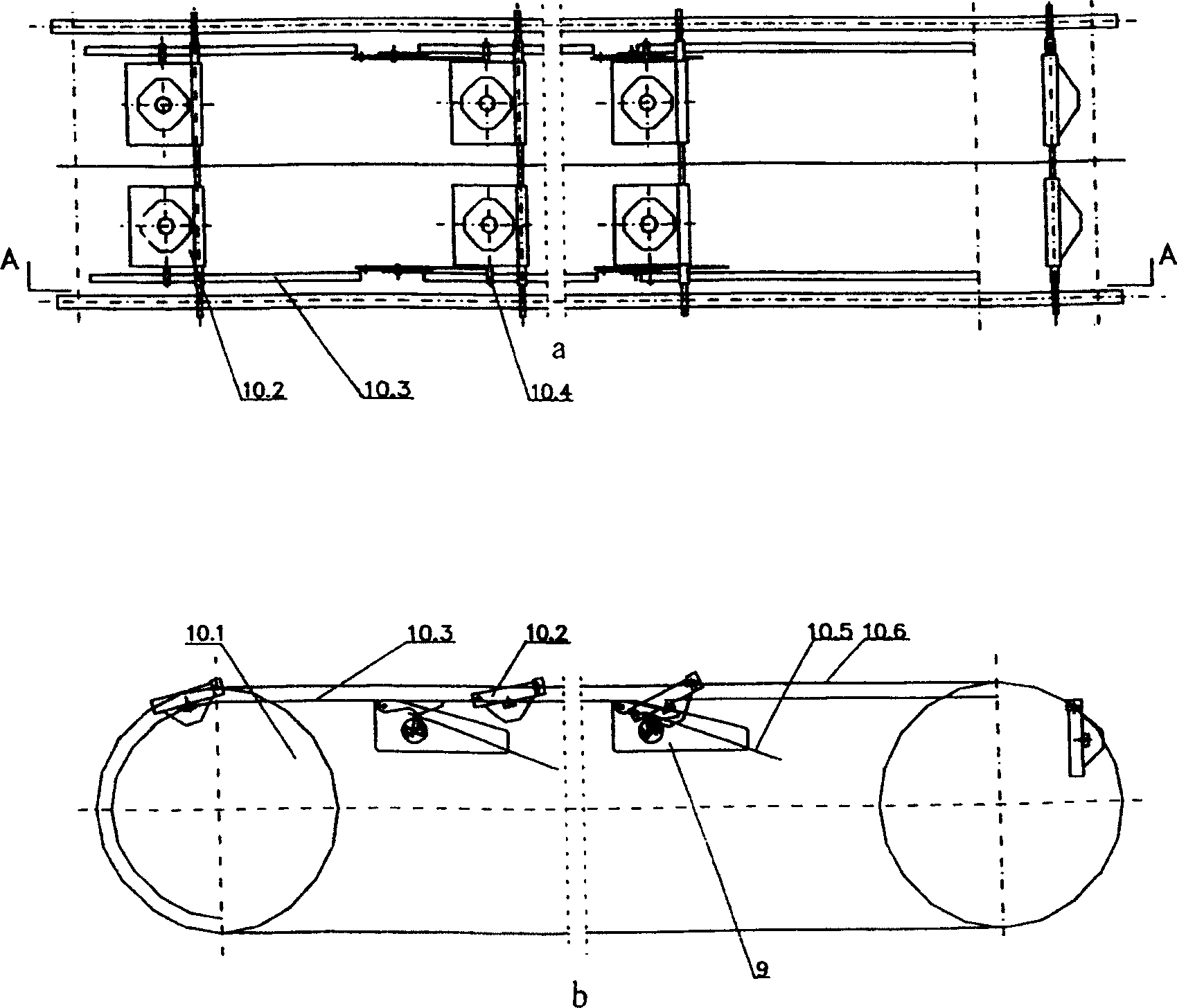

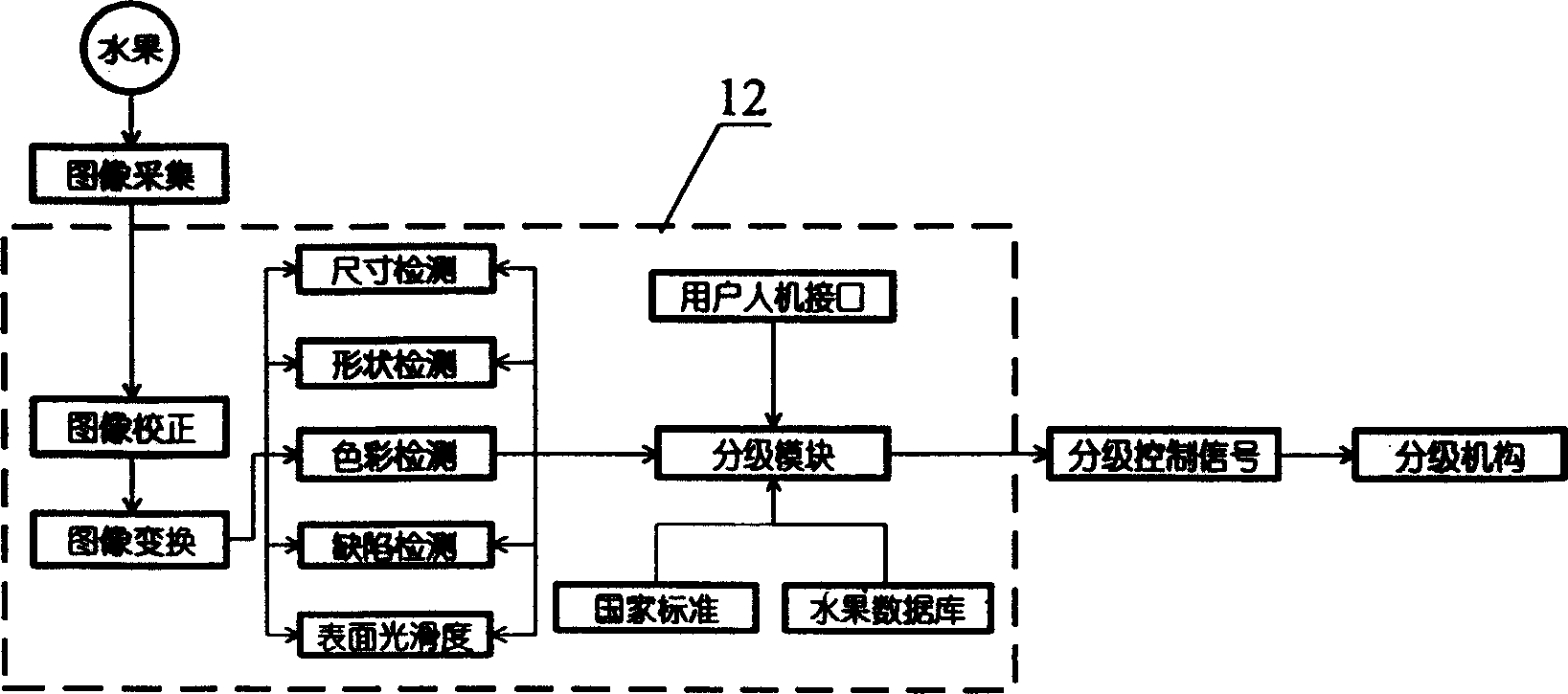

[0021] Such as figure 1 As shown, it includes an encoder 1, a conveying device 2, a light box 3, a video camera 4, a computer 5, an image acquisition card 6, a shift register group 7, and a grading mechanism controller 8 corresponding to the number of shift register groups. Mechanism 9, grading device 10, discharge port 11, fruit grading software 12; conveying device 2 and grading device 10 are composed of two sprockets and two chains surrounding the sprockets, and the power is input to the grading device 10 from the outside Then, the grading device 10 synchronously transmits it to the conveying device 2; the encoder 1 is installed on the conveying device, and is connected to the image acquisition card 6 installed in the computer through a wire; the light box 3 is installed above the conveying device; the camera 4 It is located in the light box and is connected to the image acquisition card 6 through a cable; the computer 5 is connected to the shift register group 7 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com