Delayed coking process with low circulation ratio

A technology of delayed coking and process method, which is applied in cracking, petroleum industry, non-catalytic thermal cracking, etc., and can solve the problems of poor quality of heavy coking wax oil, high construction investment and operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

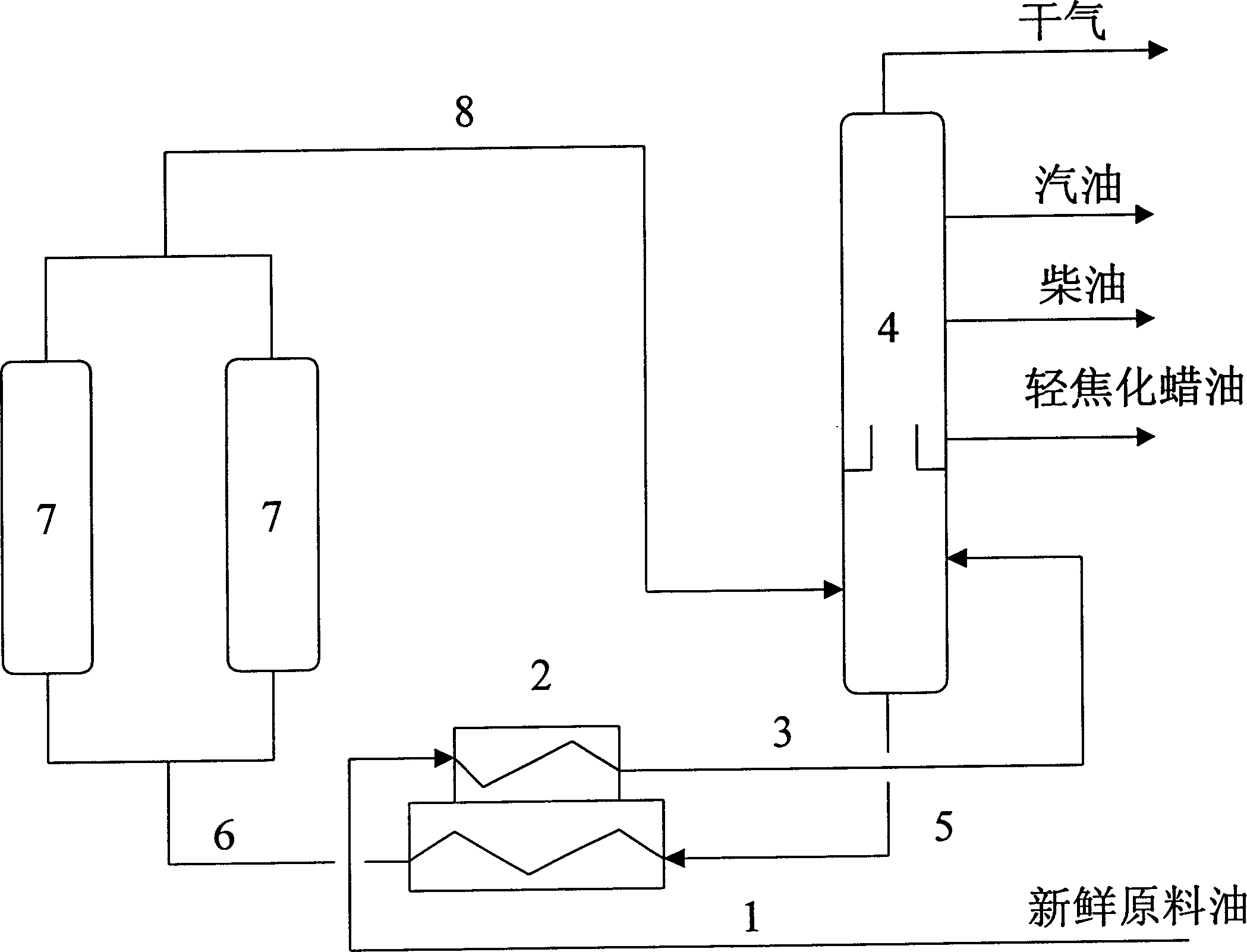

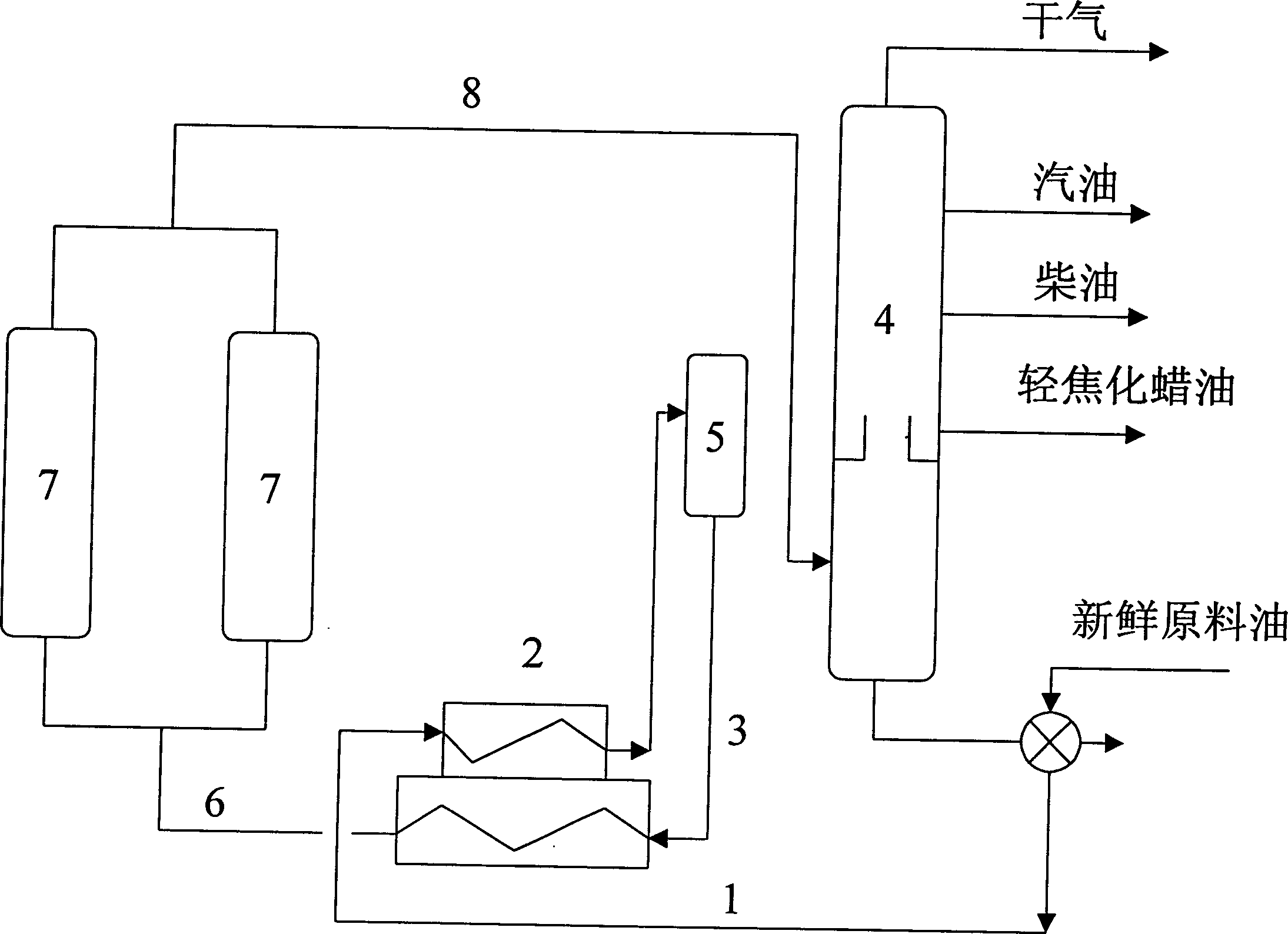

Method used

Image

Examples

Embodiment

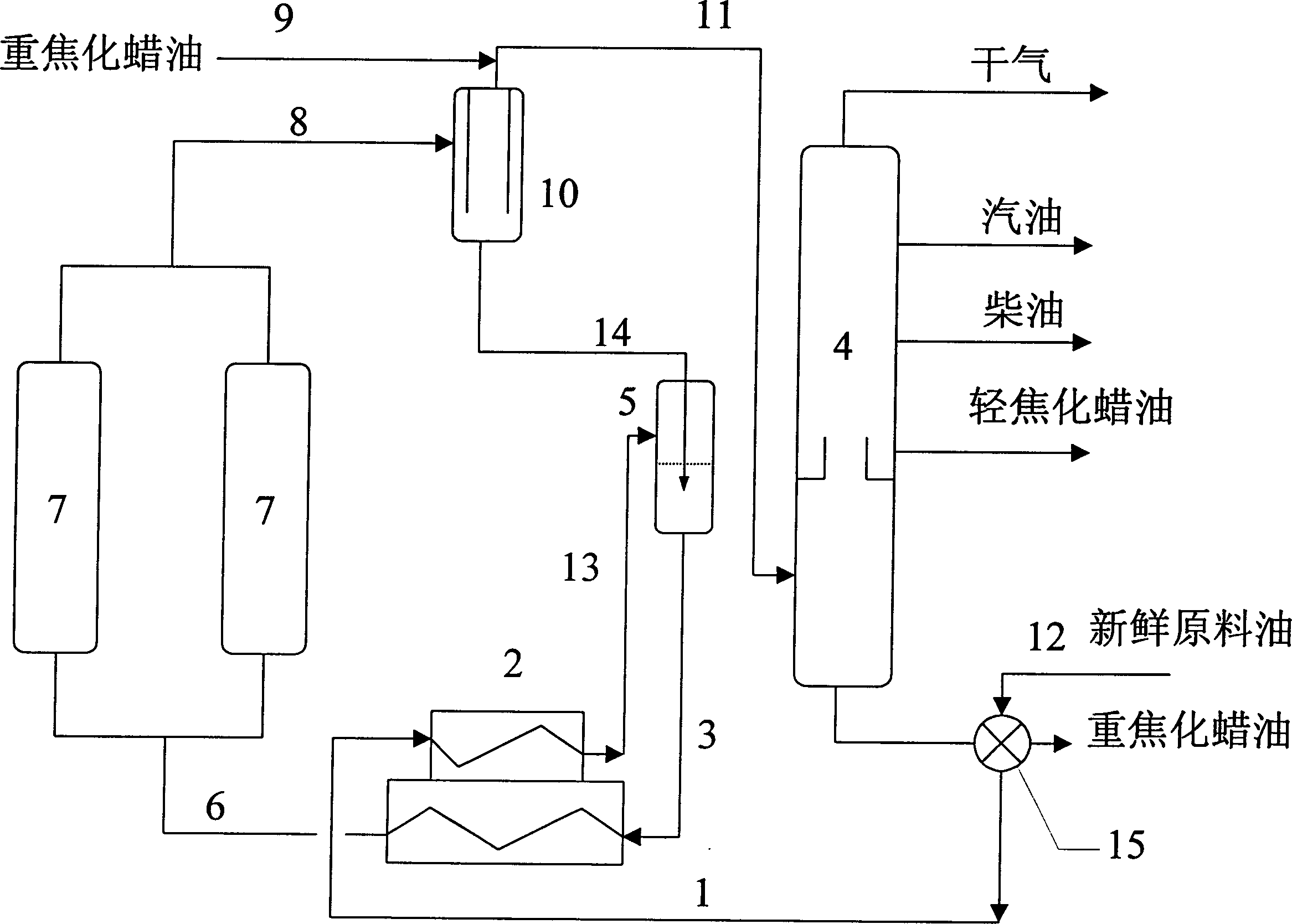

[0040] This example illustrates the case of using the low cycle ratio delayed coking process provided by the present invention.

[0041] The same vacuum residue raw material as in Comparative Example 1 is first heated to 360°C through the convection section of the heating furnace, and then enters the raw material tundish. In the raw material tundish, the coking raw material oil and the heavy coked wax oil from the cyclone separator are in a weight ratio of 0.08 : 1 After mixing, it enters the radiant section of the heating furnace and is heated to 500°C, and enters the coke tower for coking, and the coke generated by coking remains in the coke tower; A small amount of cooled heavy coker gas oil is injected into the top of the tank, the residence time of the coker gas in the cyclone separator is 1 minute, the temperature is 430°C, the coke powder and asphaltene carried in the high temperature coker gas are separated, and the purified coker gas into the fractionation tower, sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com