Method by using wet etching with non-equivalence in directions to carry out even process

An anisotropic, wet etching technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve problems such as affecting components, surface scratches, and reduced component reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

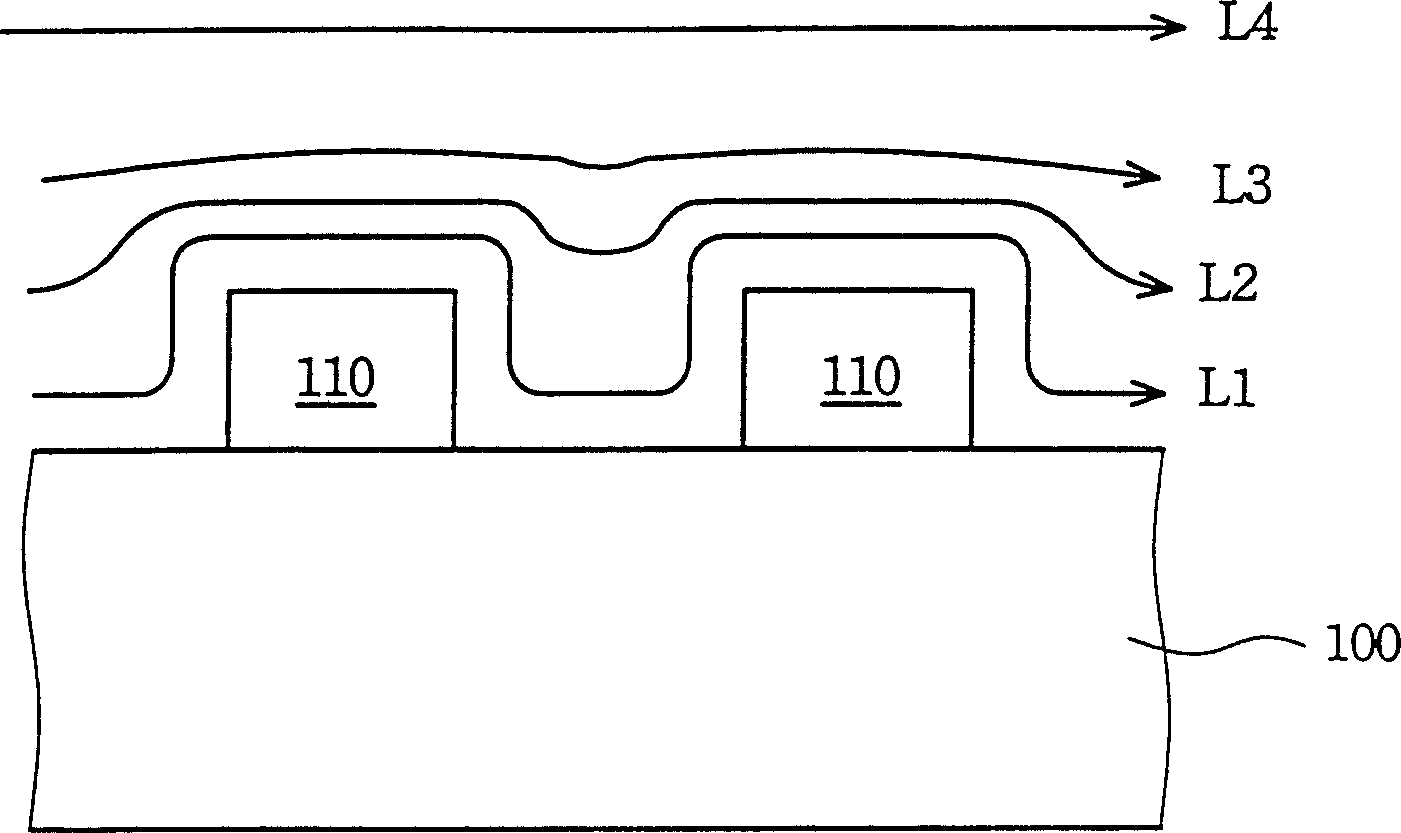

[0024] Please refer to figure 1 , figure 1 It is a schematic diagram of liquid flowing over a surface with uneven surface. There are protrusions 110 on the base 100, when the liquid flows through the surface of the base 100, according to the distance from the surface of the base 100 from near to far, in figure 1 The indicated flows are L1, L2, L3 and L4. The liquid flow L1 closest to the surface of the substrate 100 has the slowest flow velocity because it encounters the protrusion 110 on its flow path. On the contrary, the liquid flow L4 farthest from the surface of the substrate 100 has the fastest flow speed because it does not encounter any obstacles on its flowing path.

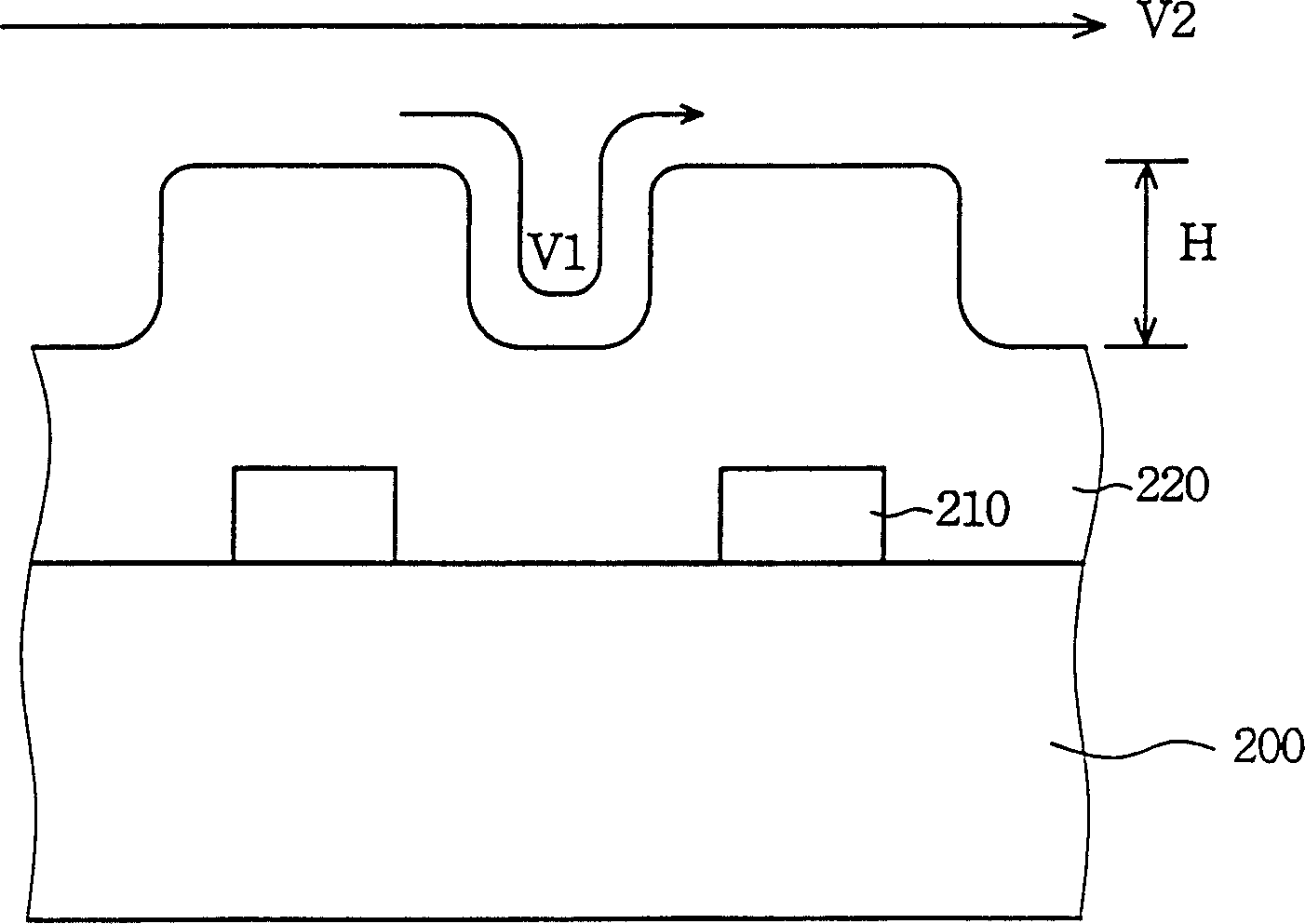

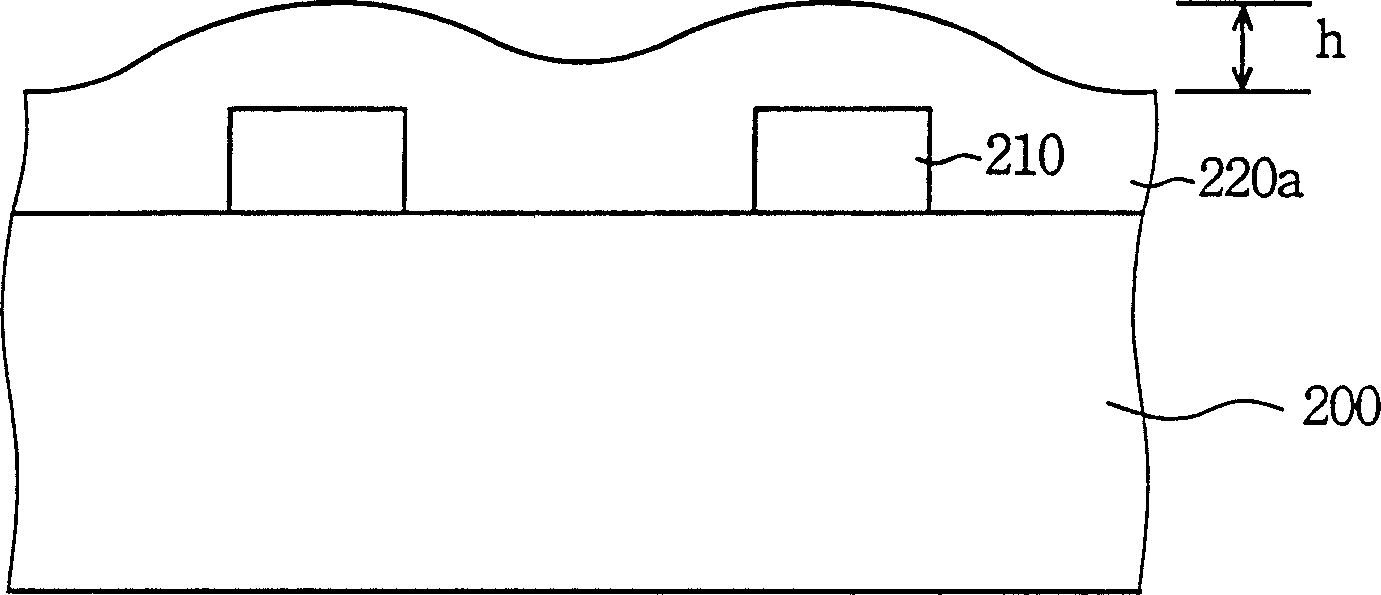

[0025] Please refer to Figure 2A-2B , which is a cross-sectional view showing a planarization process using an anisotropic wet etching method according to a preferred embodiment of the present invention. Please refer to Figure 2A , there is a wire 210 on the substrate 200, and the wire 210 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com