Dry film and method for producing colorful color filter with dry film

A color filter, dry film technology, applied in the direction of filters, optics, optical components, etc., can solve the problems of difficult uniformity control, affecting the uniformity of the crystal packet gap, and affecting the uniformity and thickness of the columnar layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

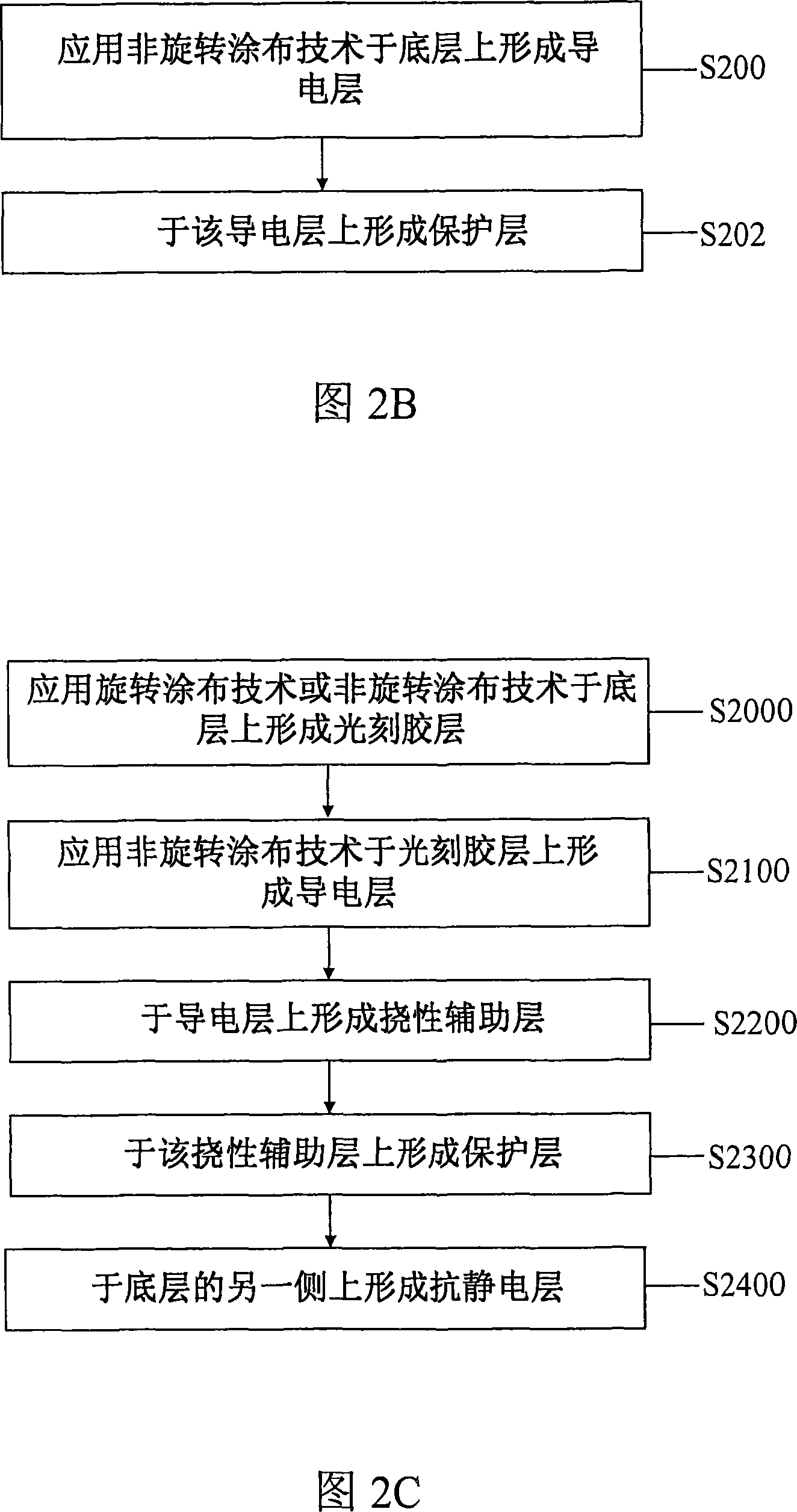

[0060] Please refer to FIG. 2A , which is a dry film according to a preferred embodiment of the present invention, which is mainly used to make a conductive layer of a color filter. The composition of this dry film structure can comprise: bottom layer (Basefilm) 202, be positioned at the antistatic layer 201 on one side of bottom layer 202, be positioned at the photoresist layer 203 on the other side of this bottom layer 202, conductive layer 204 be positioned at the photoresist On the adhesive layer 203 , a flexible auxiliary layer (Cushion layer) 205 is located on the conductive layer 204 and a protection layer (Cover film) 206 is located on the flexible auxiliary layer 205 . It should be noted that the dry film structure of the present invention described here is only an example for the convenience of implementation. In other practical examples, the composition of the dry film structure can be changed or increased or decreased arbitrarily, and is not used to limit the scope ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com