Method for producing color filter

A technology of color filter and manufacturing method, applied in optics, optical components, microlithography exposure equipment, etc., can solve problems such as interference, incomplete shading, and unsatisfactory thickness control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

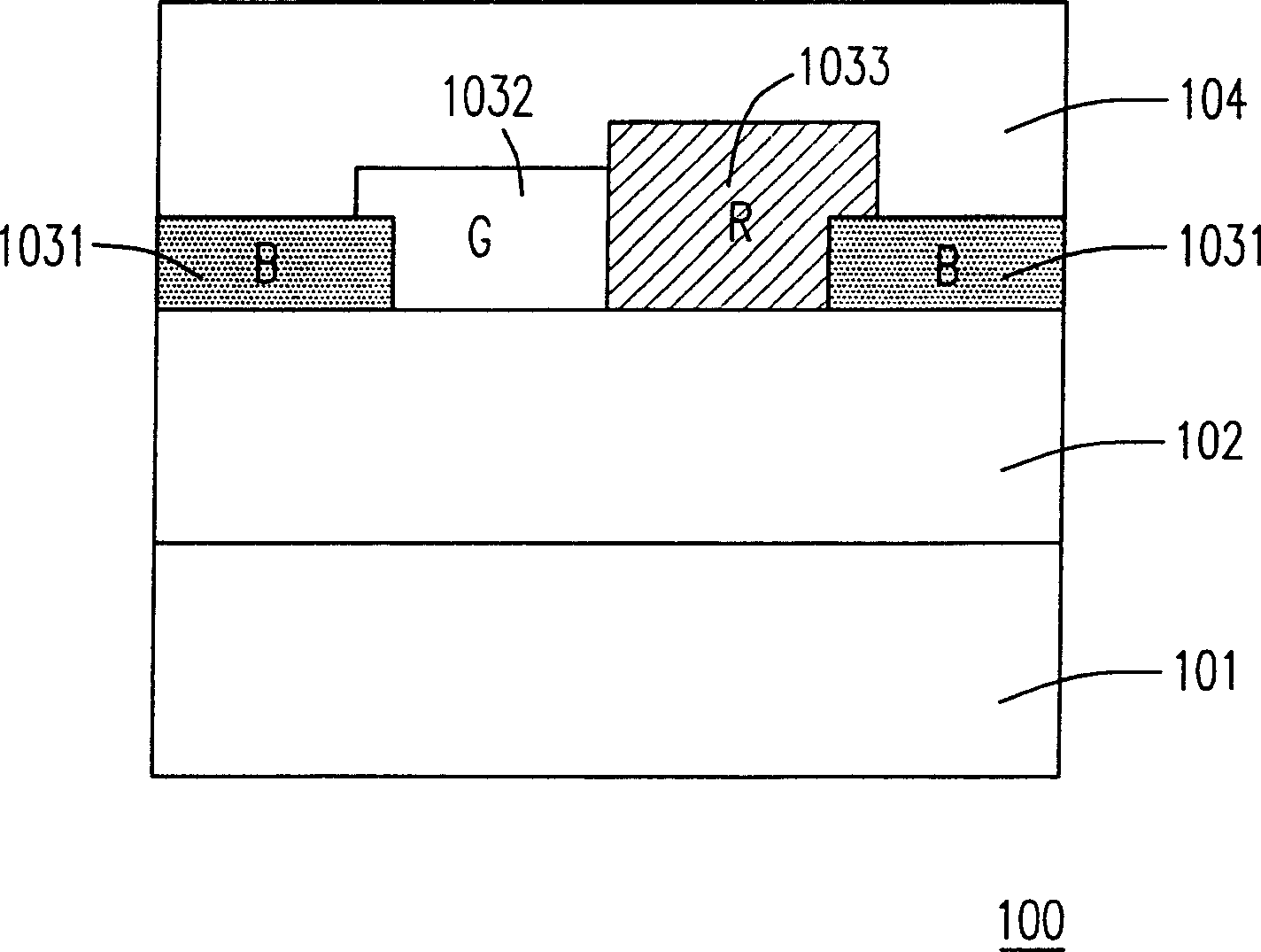

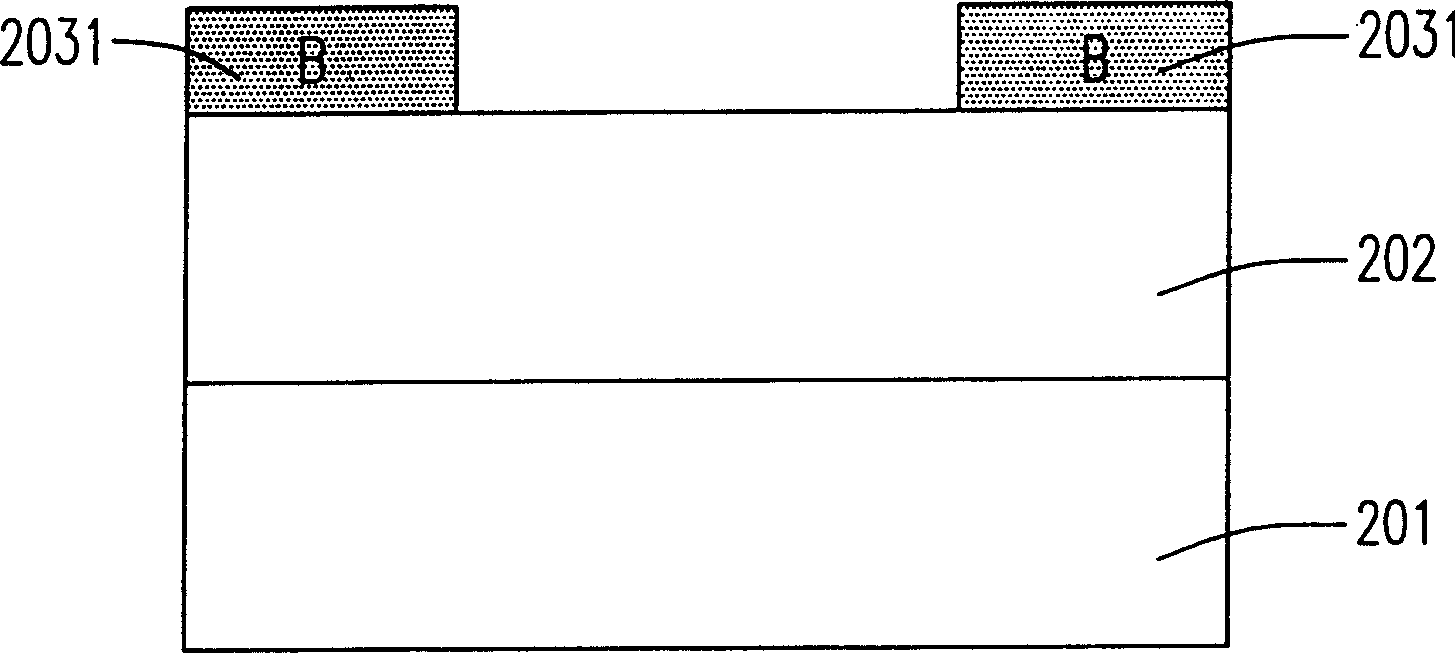

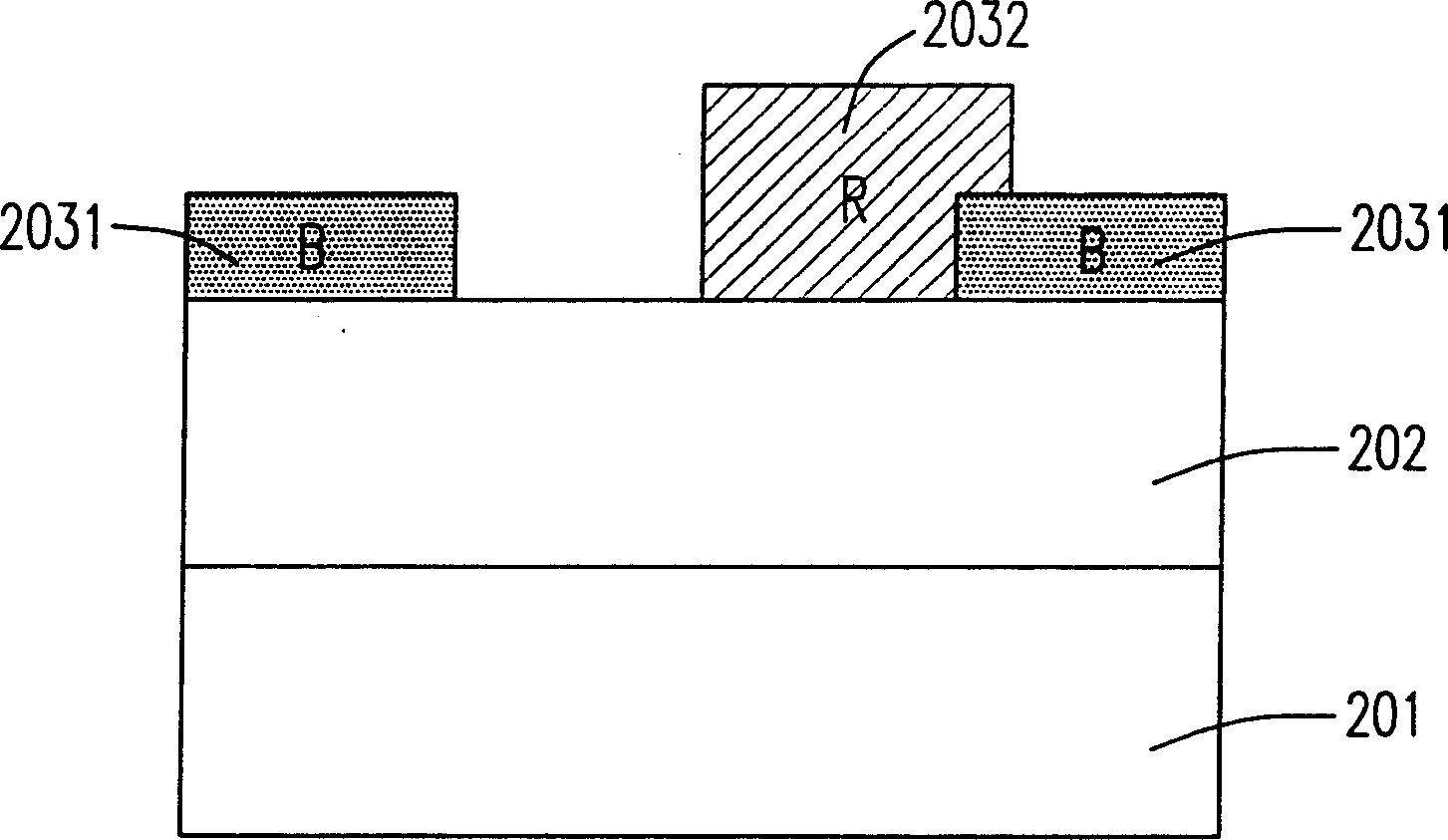

[0029] Please refer to Fig. 2 (a) to (e), which is a flow chart of a preferred embodiment of the manufacturing method of the color filter of this case.

[0030] First, as shown in FIG. 2(a), a transparent and planarized dielectric layer 202 is formed on a semiconductor substrate 201, and then a color pixel with a pattern ratio of 25% is formed on the dielectric layer 202, for example Blue pixel 2031. The formation method is to coat a layer of blue photoresist on the dielectric layer 202, which is a blue dye (pigment) negative photoresist, and then perform an exposure process and a development process to harden the exposed blocks , so that the blue photoresist is transformed into many blocky blue pixels 2031, as shown in FIG. 3(a).

[0031] Next, as shown in FIG. 2( b ), another color pixel with a pattern ratio of 25%, such as a red pixel 2032 , is formed. The formation method is to coat a layer of red photoresist on the dielectric layer 202 and the blue pixel 2031. This red ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com