Equipment for in-line exchange of substrate in vacuum chamber

A vacuum chamber and substrate technology, applied in vacuum evaporation plating, metal material coating process, coating, etc., can solve the problem that the uniformity of the film cannot be guaranteed, and achieve the effect of shortening the development cycle and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Different deposition parameters are realized by using a dynamic film changing mechanism for comparative work.

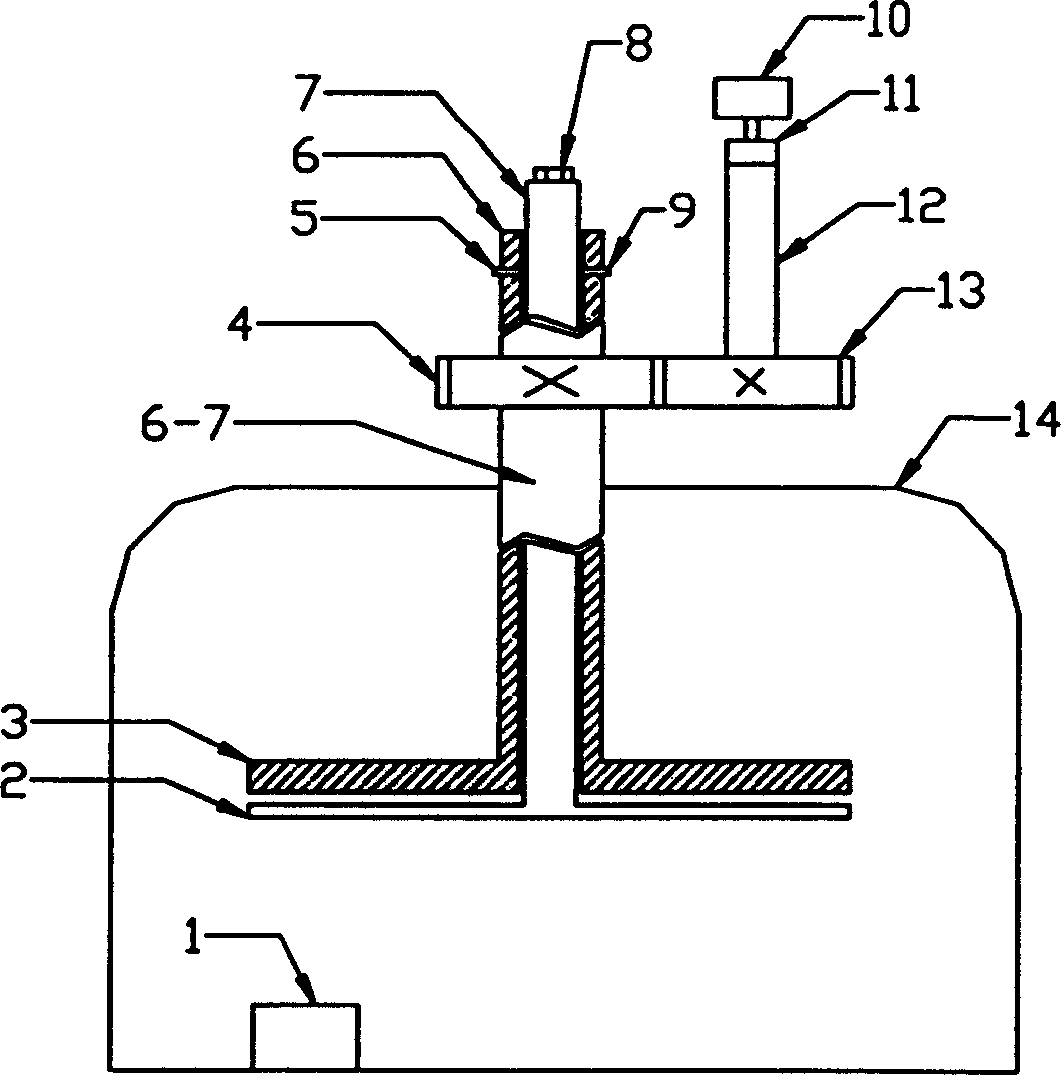

[0019] The above-mentioned first structure is adopted in the rotating fixture part of the ion beam sputtering coating machine, such as figure 1 shown.

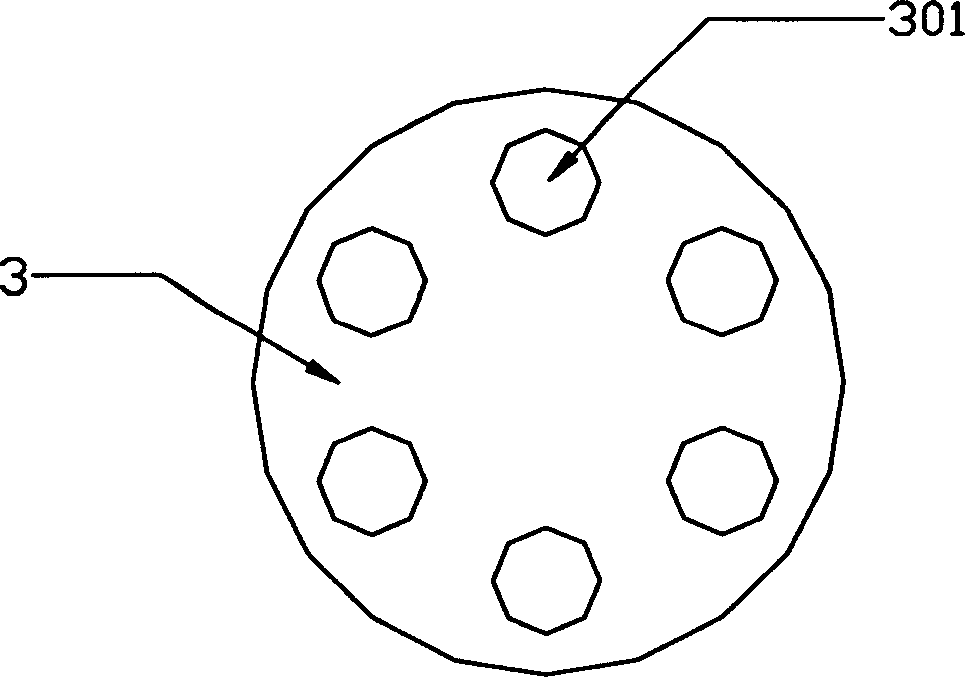

[0020] image 3 It is a schematic diagram of the plane of the circular substrate holder 3 used, and six holes 301 are evenly distributed on the substrate holder 3 to place the substrate to be coated. Figure 4 It is a schematic plan view of the used baffle plate 2 , its apex angle is 300°, and the notch 201 is fan-shaped with an angle of 60°. The baffle plate 2 has the same radius as the substrate holder 3 . Before coating, adjust the relative position of the substrate fixture 3 and the baffle 2, so that the baffle 2 just covers five substrates, and the remaining one is at the 60° fan-shaped gap 201 of the baffle, and is fixed with two top wires 5 and 9 The relative position of the hollow rotati...

Embodiment 2

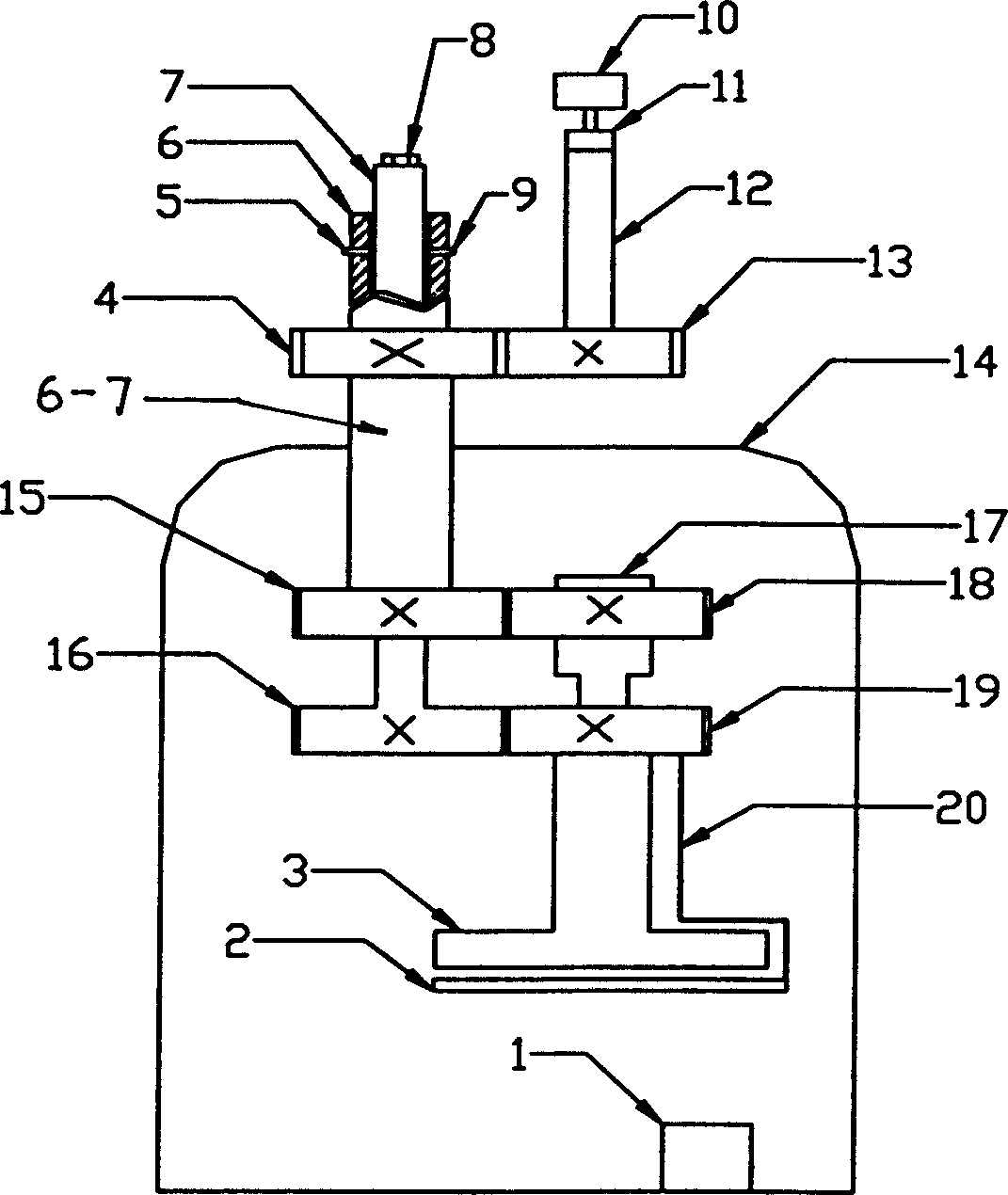

[0021] Embodiment 2: The accumulation function of deposition time is realized by using a dynamic film changing mechanism.

[0022] In order to study the effect of deposition time on film properties, such as the relationship between film properties and time-dependent changes during film growth, it is necessary to prepare samples with different deposition times under the same deposition parameters. Using devices such as figure 1 The first structure shown. In order to improve efficiency, the shape of the baffle plate 2 adopted in this embodiment is a fan shape with an apex angle of 180°. Its gap 201 is also a sector of 180°. The film preparation time is one, two, four, five, seven and eight hours respectively. Initially, the relative positions of the substrate holder 3 and the baffle 2 are adjusted so that the baffle 2 just covers three substrates to be coated, and the other three substrates are exposed outside the baffle 2 . The positions of substrate holder 3 and baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com