Improved method of measuring vacuum pressure in sealed vials

A technology of vacuum pressure and internal pressure, applied in the application of electrical devices to test fluid tightness, vacuum gauges using ionization effects, etc., can solve problems such as increased errors and delays that have not been eliminated, and achieve fast voltage jump rates and fast The effect of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

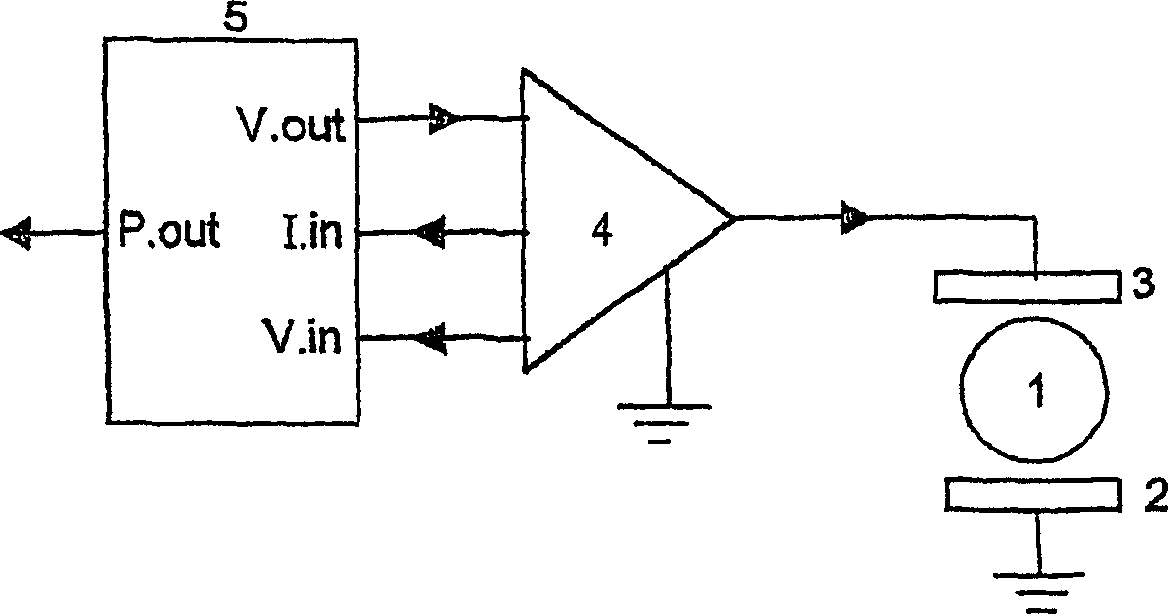

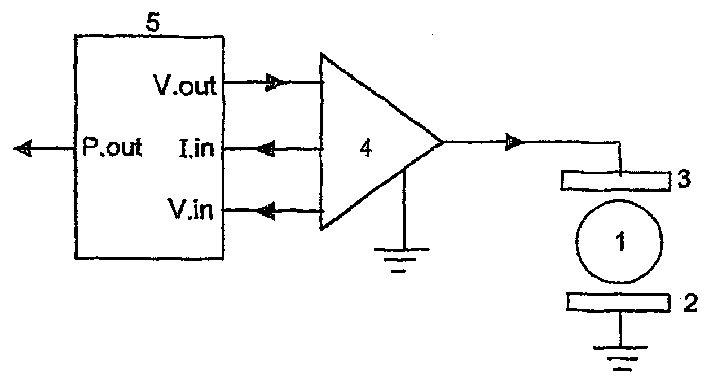

[0026] refer to figure 1 , the container 1 to be tested is located between a grounded electrode 2 and an electrode 3 driven by a high-frequency, high-voltage source 4, which is typically capable of generating a voltage of 20,000 volts and a frequency of hundreds of thousands Weekly voltage.

[0027] The controller 5 is provided with input signals representing the electrode voltage "V.in" and the electrode current "I.in". The controller 5 is further provided with a means of controlling the output voltage of the source 4 through the output signal "V.out".

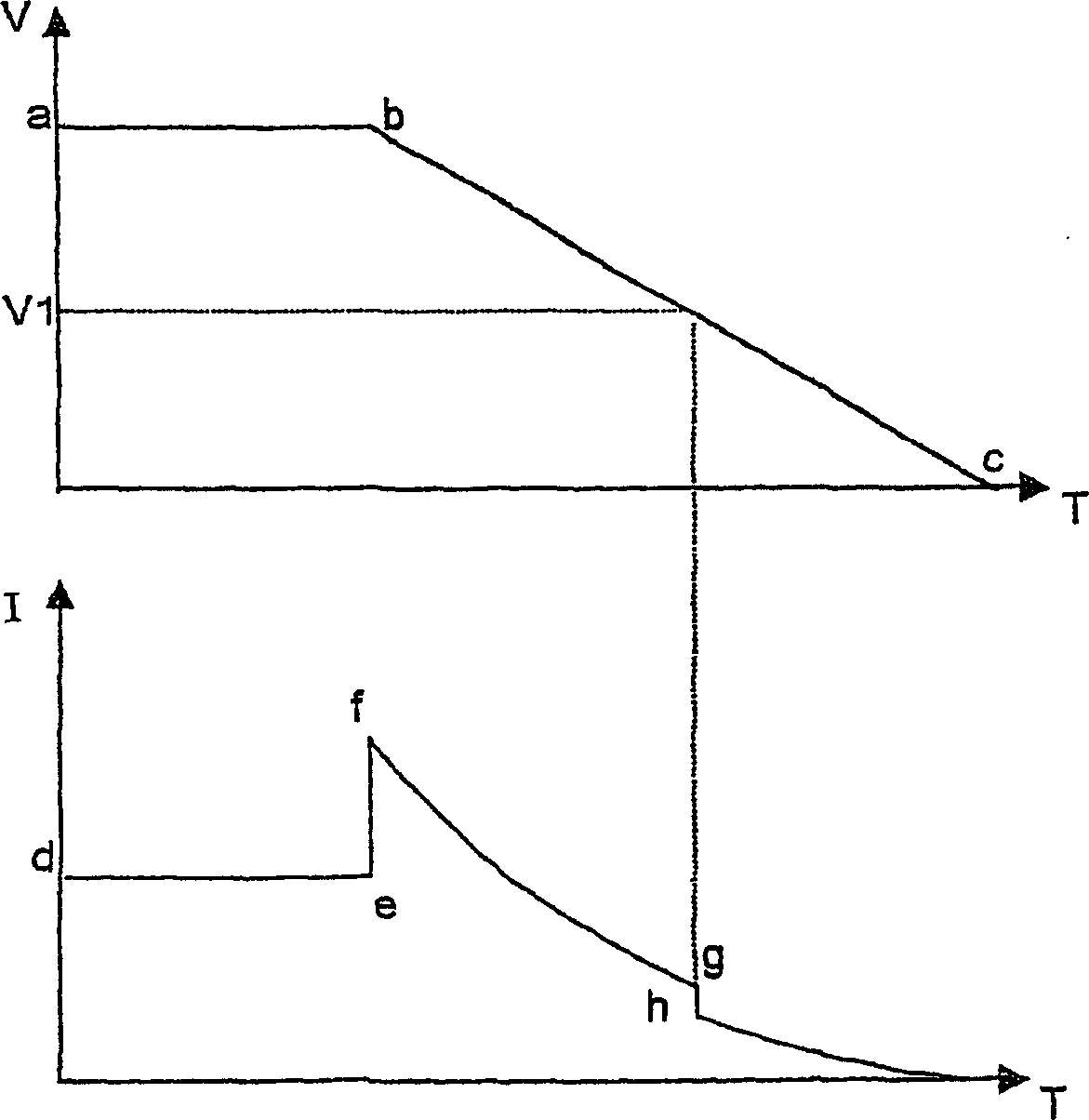

[0028] refer to figure 2 , the graph shows the electrode voltage "V" and the corresponding electrode current "I" during a typical test sequence. Typical time periods for test sequences are on the order of a few hundred milliseconds. At the beginning of the pressure measurement sequence, the maximum voltage shown at point "a" is applied. The corresponding electrode current of the non-ionizing bottle is shown at point "d"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com