Bush cutting machine

A technology for cutters and bushes, applied in the direction of harvesters, lawn mowers, cutters, etc., can solve problems such as inspection and adjustment troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

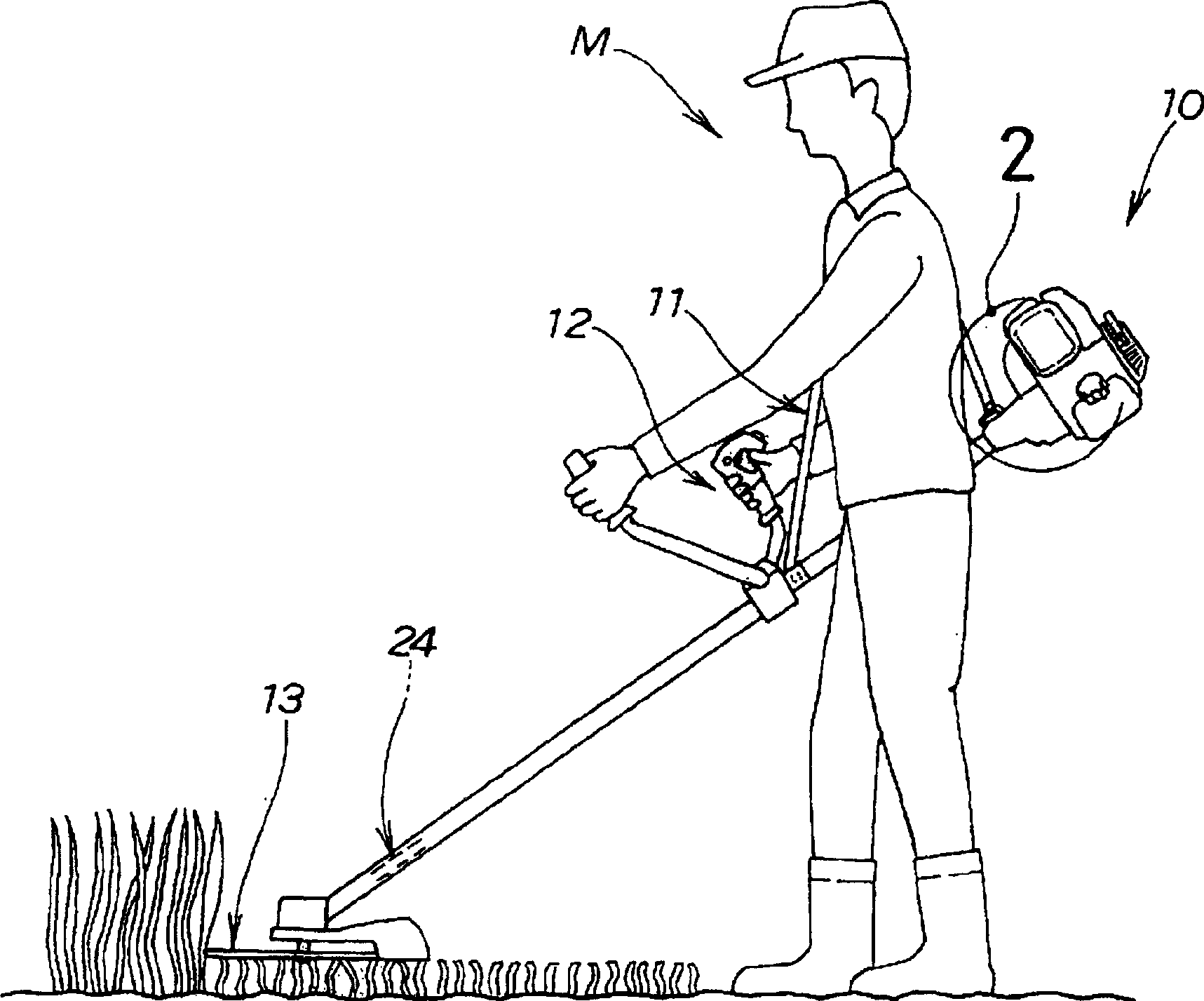

[0015] first reference figure 1 , when cutting bushes, the bush cutter 10 according to the present invention is hung on the shoulders of the operator M through the suspension belt or the shoulder strap 11 while holding the controller 12 firmly. Reference numeral 13 denotes a cutting blade for cutting bushes.

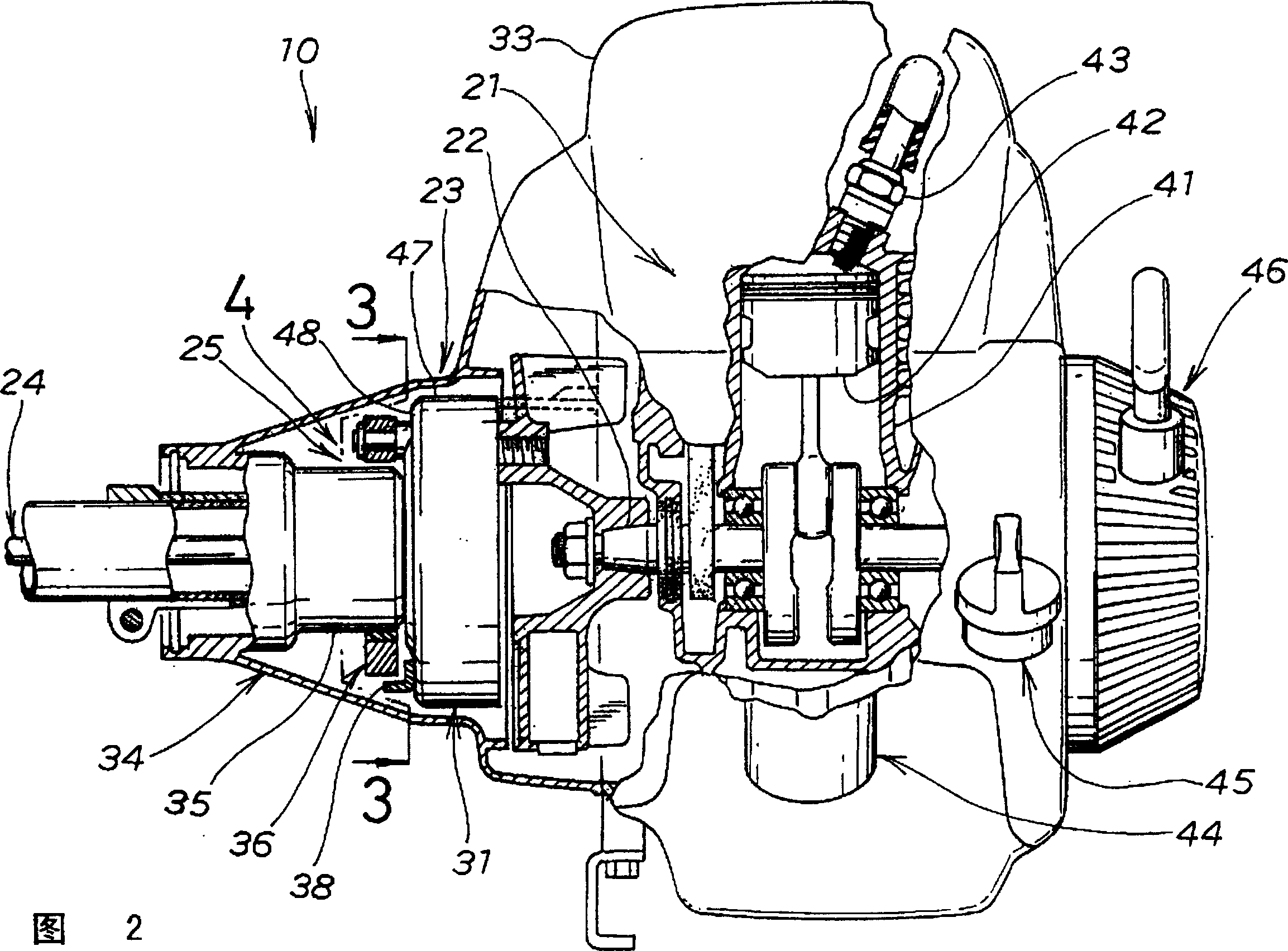

[0016] As shown in FIG. 2, the bush cutter 10 has a motor 21, a centrifugal clutch 23 designed to establish a drive connection when the number of revolutions of a crankshaft 22 serving as an output shaft of the motor 21 exceeds a predetermined value for transfer rotational force or torque to figure 1 The blade drive shaft 24 of the cutting blade 13 shown in , and the automatic braking mechanism 25 .

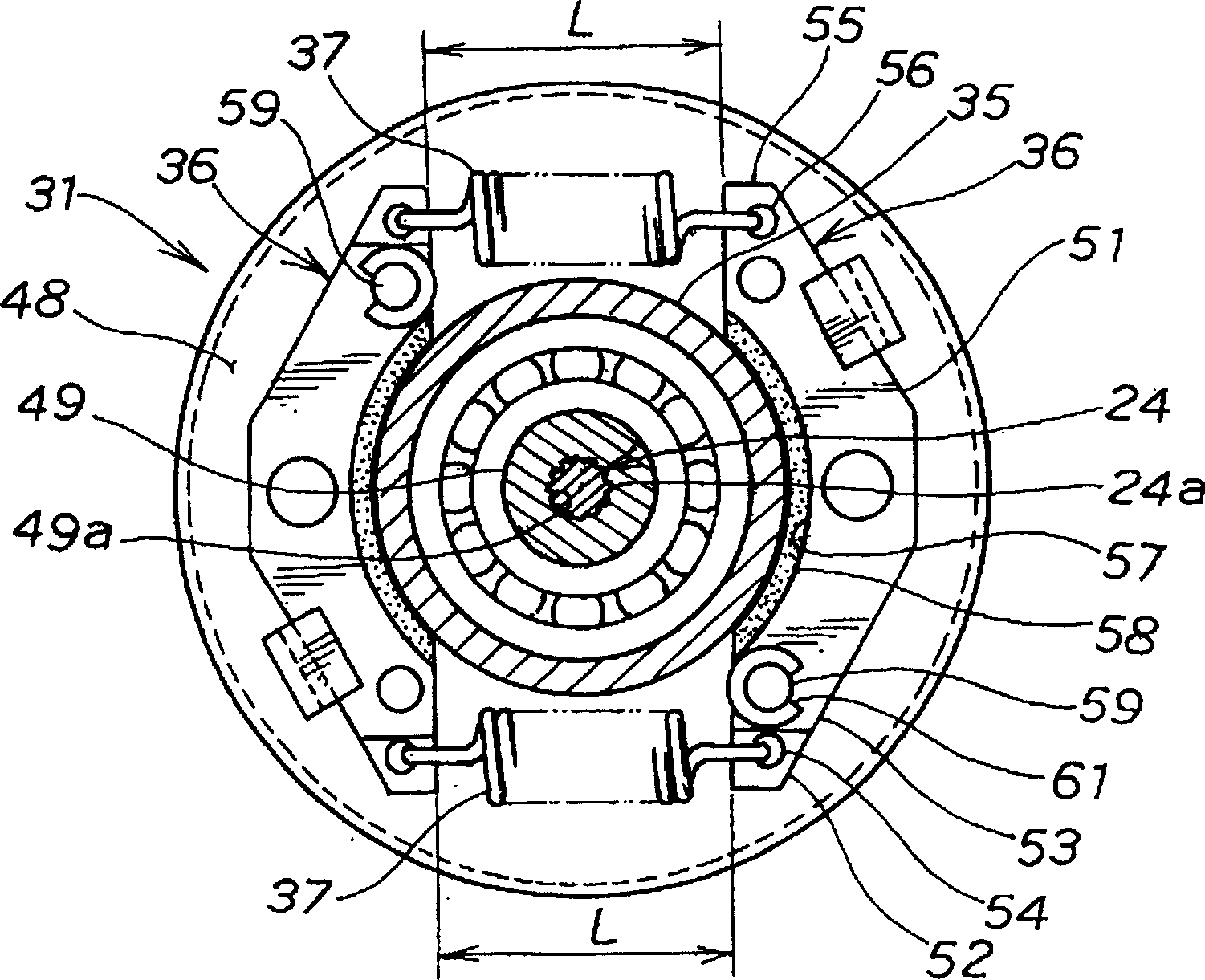

[0017] The centrifugal clutch 23 has a clutch drum 31 mounted on the blade drive shaft 24, a centrifugal pivot member 32 (see Figure 4 ) is arranged on the crankshaft 22 of the motor 21 and placed in the clutch drum 31, and the clutch housing 34 is connected to the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com