Transport devices and methods for film bags

A transfer device, film bag technology, applied in the direction of transmission, transportation and packaging, packaging, etc., can solve problems such as discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

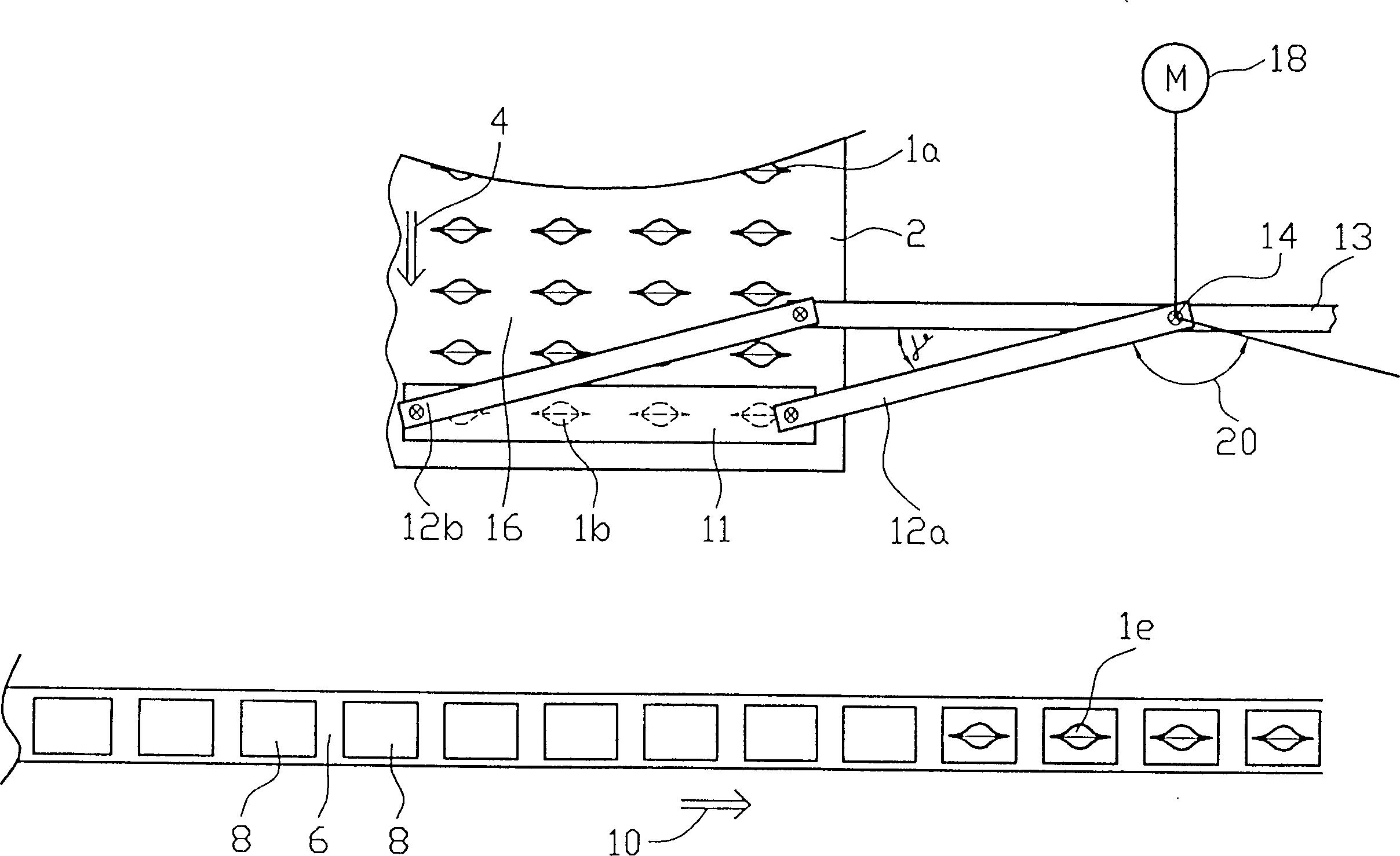

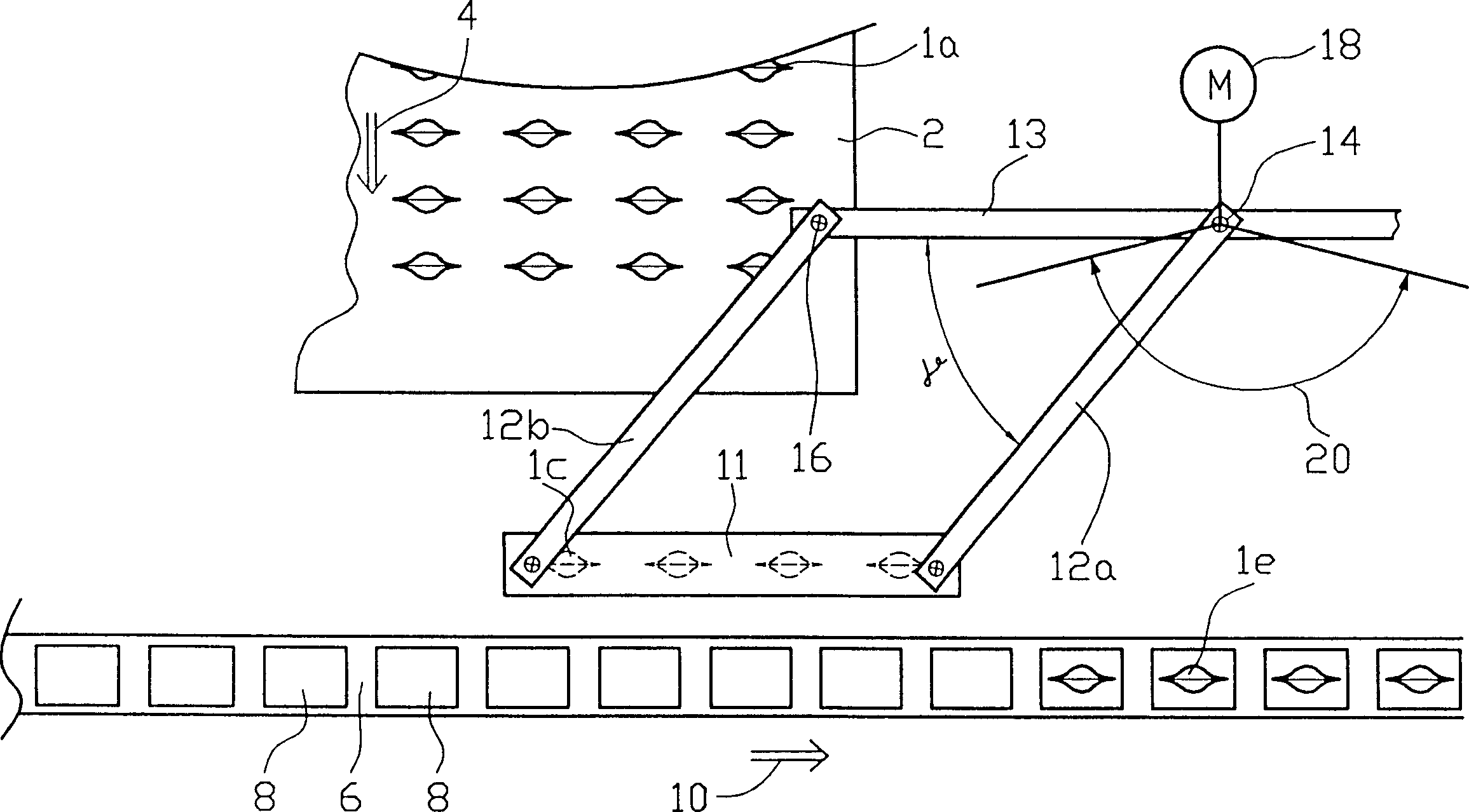

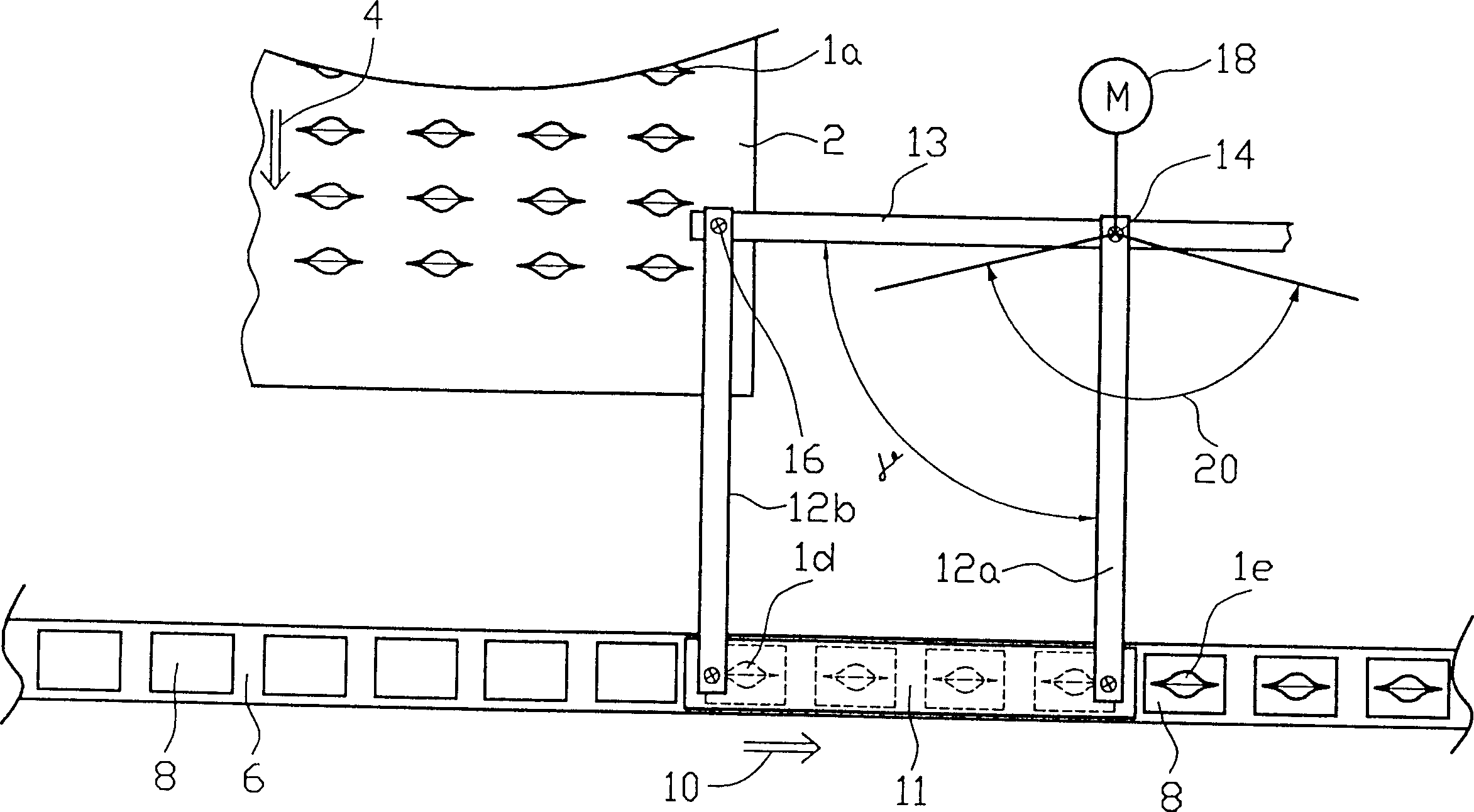

[0028] Figure 1a to Figure 1c The translocation region is shown. Such a transfer area can be found, for example, in a beverage filling system. The filled and closed beverage film bag 1a is transported by the transfer device to a conveying device which, for example, transports the beverage film bag to a beverage tube installation station.

[0029] The filled and closed beverage film pouches 1 a are supplied by a supply device 2 in a supply direction 4 .

[0030] 13 denotes a conveyor having pivotable lever arms 12a, 12b hinged thereto at pivot points 14 and 16. An electric motor 18 is provided for providing pivotal movement in the direction of arrow 20 . 11 denotes a transverse bar, which has a bottom with clamping means, which are not expressly shown in Figures 1a to 1c . In Fig. 1, the film bag 1b transferred by the transverse bar 11 is indicated by dashed lines. The transverse bar 11, the two lever arms 12a, 12b and the conveyor 13 form a parallelogram with a variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com