Detection system for wall thickness and defect of oil gas pipeline

A technology for oil and gas pipeline and defect detection, applied in general control systems, electrical/magnetic thickness measurement, control/regulation systems, etc. The effect of reducing the towing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

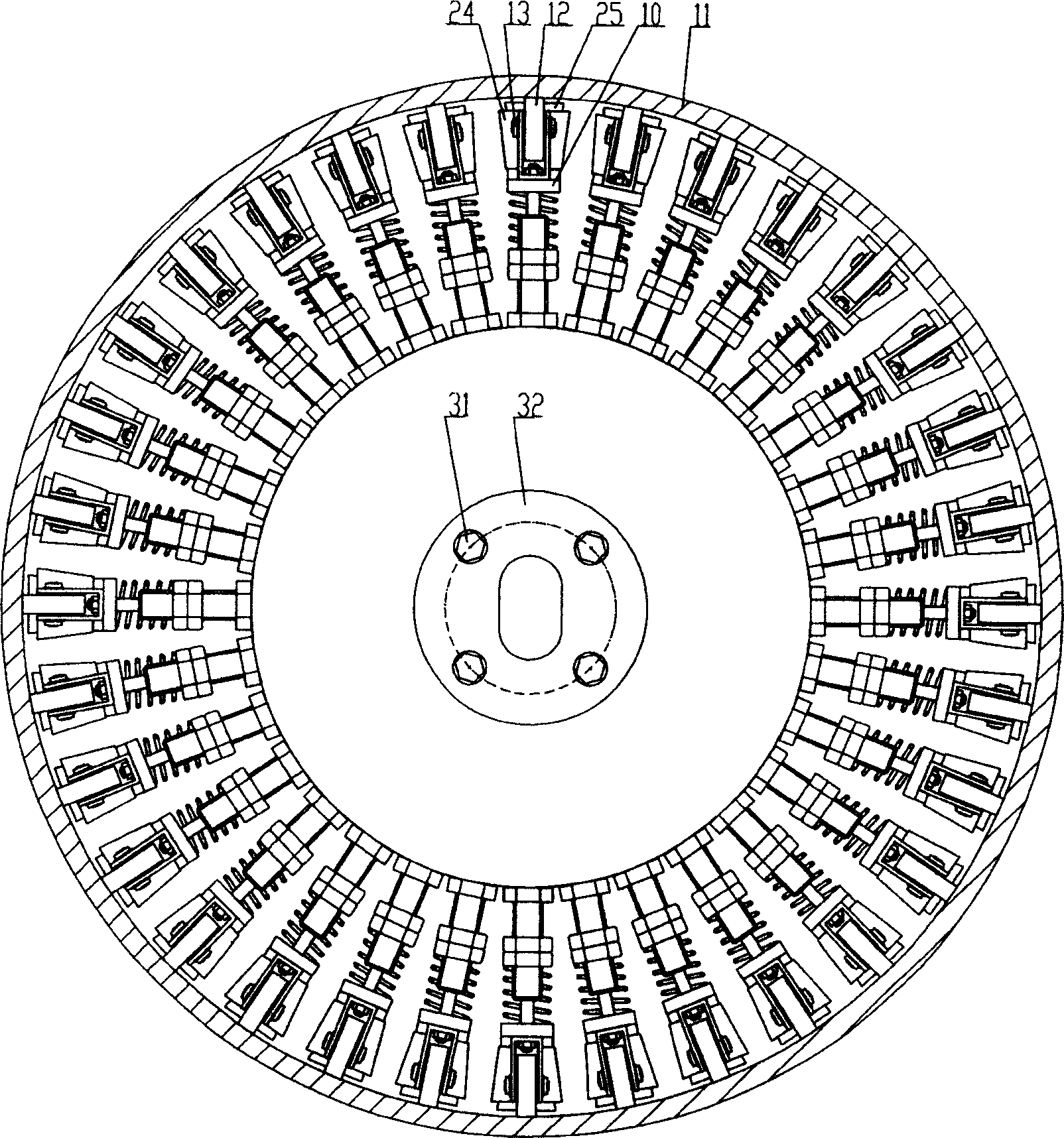

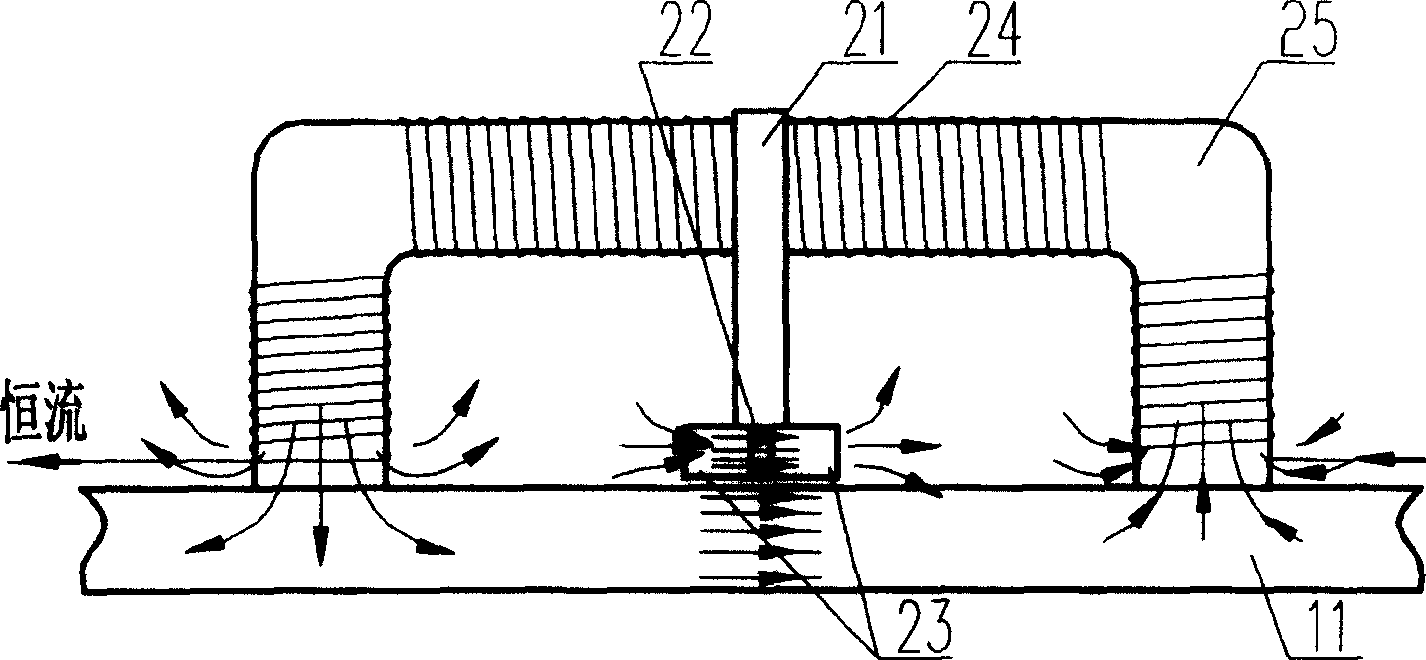

[0017] The present invention includes a sensor fixing device, 32 sets of circumferential array measuring head components capable of realizing radial coarse adjustment and self-adaptive adjustment of springs, and electronic devices for realizing measurement process control, signal acquisition and data processing, and ambient temperature compensation. control system. The specific description is as follows:

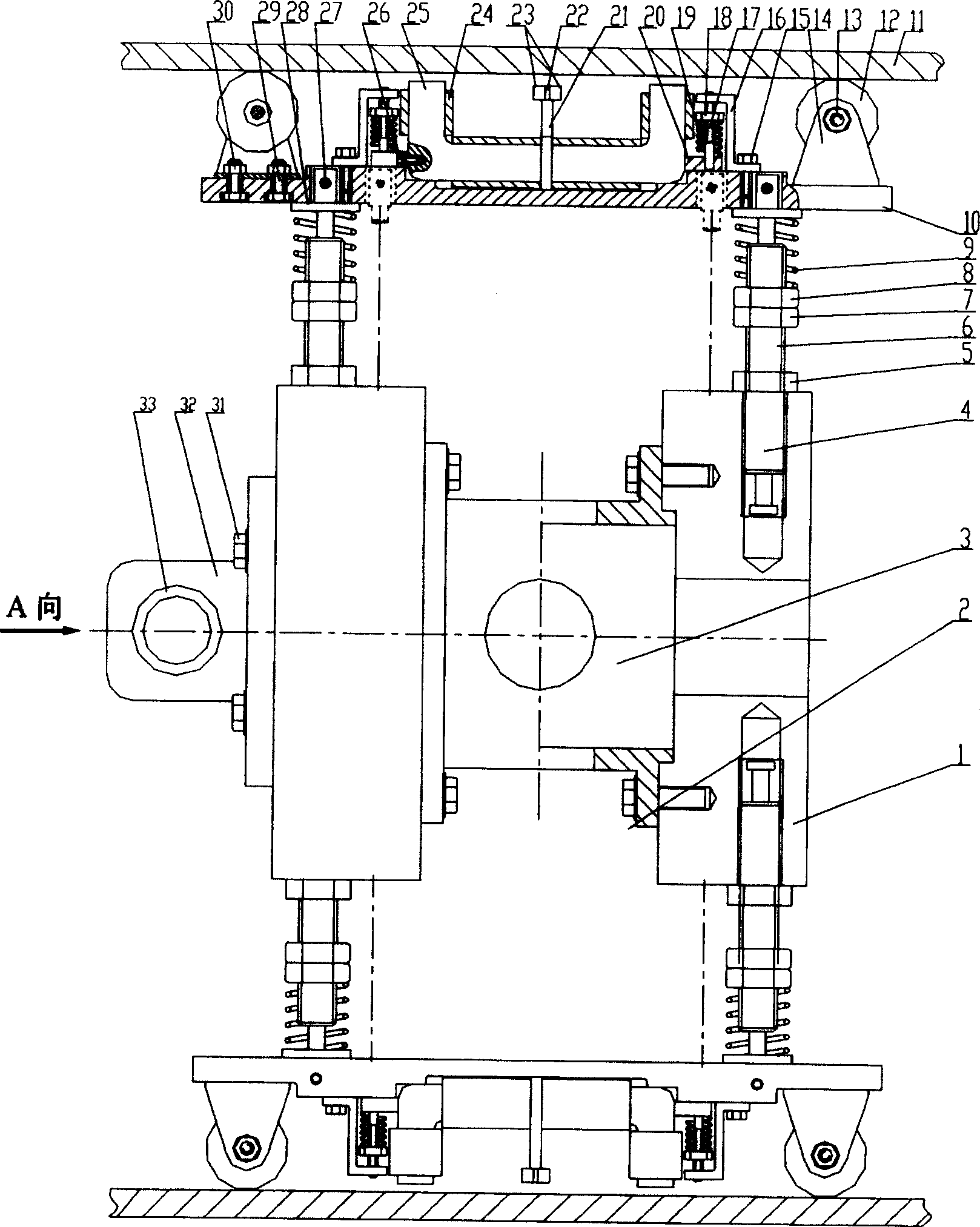

[0018] The overall structure of the detection system of the present invention is as follows: figure 1 , figure 2 As shown, the sensor fixing device is composed of a disc body 1, a disc body connector 3, a bolt 2, a connecting bolt 31, a ball joint connector 32 and a ball joint 33. The two disk bodies 1 and the disk body connector 3 form a whole through the bolt 2 to form a symmetrical structure, and the ball joint 33 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com