Biodegradation formation article and its mfg. method

A technology of biodegradability and manufacturing method, applied in the field of biodegradable moldings and its manufacturing, can solve the problem of low wet tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

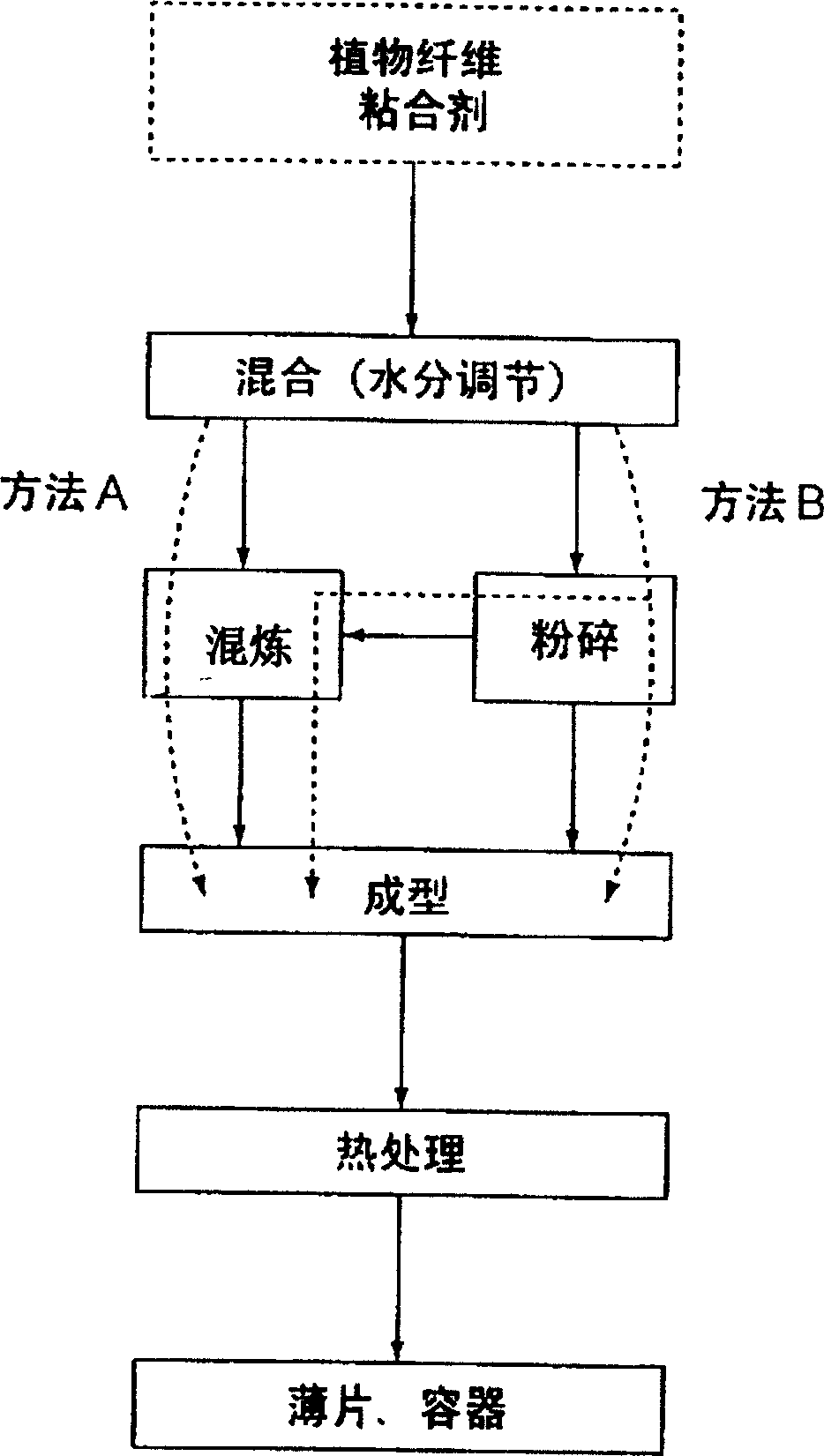

Method used

Image

Examples

Embodiment 1

[0112] Waste paper (based on the quality of the whole waste paper, newspaper 1 / 2, copy paper 1 / 2) and cow dung according to the mass ratio (waste paper: cow dung) 80:20, 60:40, 40:60, or 20:80 mixed, and weighed in 10g of the total mass. Then, put it into a pulverizer together with 500ml of water for 10 minutes of pulverization, distribute the dispersion solution evenly on a flat-bottomed sieve [about 80 mesh (180 μm), diameter 19cm], and make a film while removing water . Spread this preformed film on a chrome-plated flat plate, squeeze out the moisture with a roller, and heat it in a constant temperature box at 150° C. for 30 minutes.

Embodiment 2

[0114] In addition to waste paper (based on the quality of the whole waste paper, newspaper 1 / 2, copy paper 1 / 2), cow dung and fresh garbage, according to the mass ratio (waste paper: cow dung: fresh garbage) 60: 20:20, 40:40:20 or 20:60:20 were mixed and weighed in 10 g of the total mass, the rest were exactly the same as in Example 1.

Embodiment 3

[0116] In addition to mixing waste paper (based on the quality of the whole waste paper, newspaper 1 / 2, copy paper 1 / 2) and fresh garbage, according to the mass ratio (waste paper: fresh garbage) 80:20, and the total mass Quantity 10g is taken except that all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com