Method for flame cutting continuous casting billets laterally

A continuous casting billet and flame cutting technology is applied in the field of cutting the continuous casting billet with flame on the side of the continuous casting billet, which can solve the impact on the product quality and economic benefit of the enterprise, increase the amount of cutting head and tail cutting of the billet, and the processing effect of the next process. and other problems, to achieve the effect of eliminating the influence of the rolling process, convenient operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

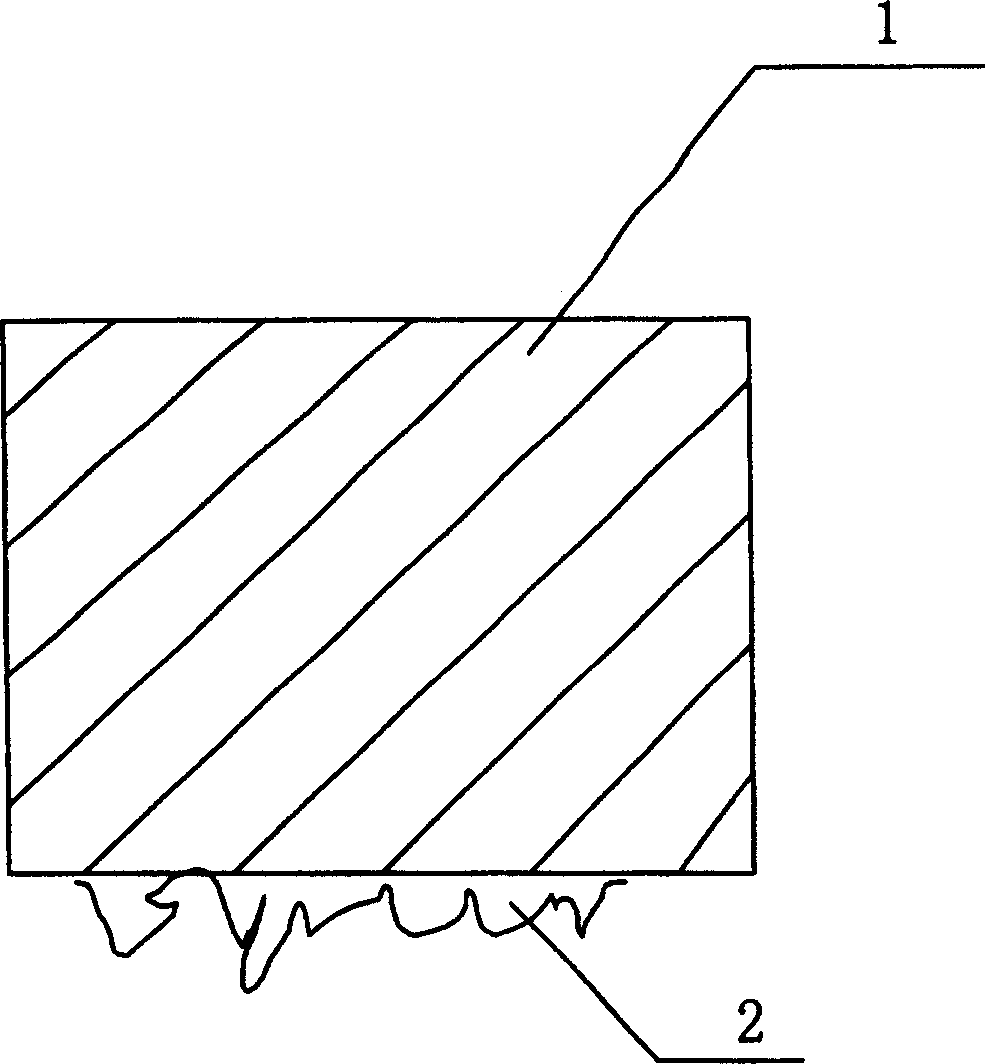

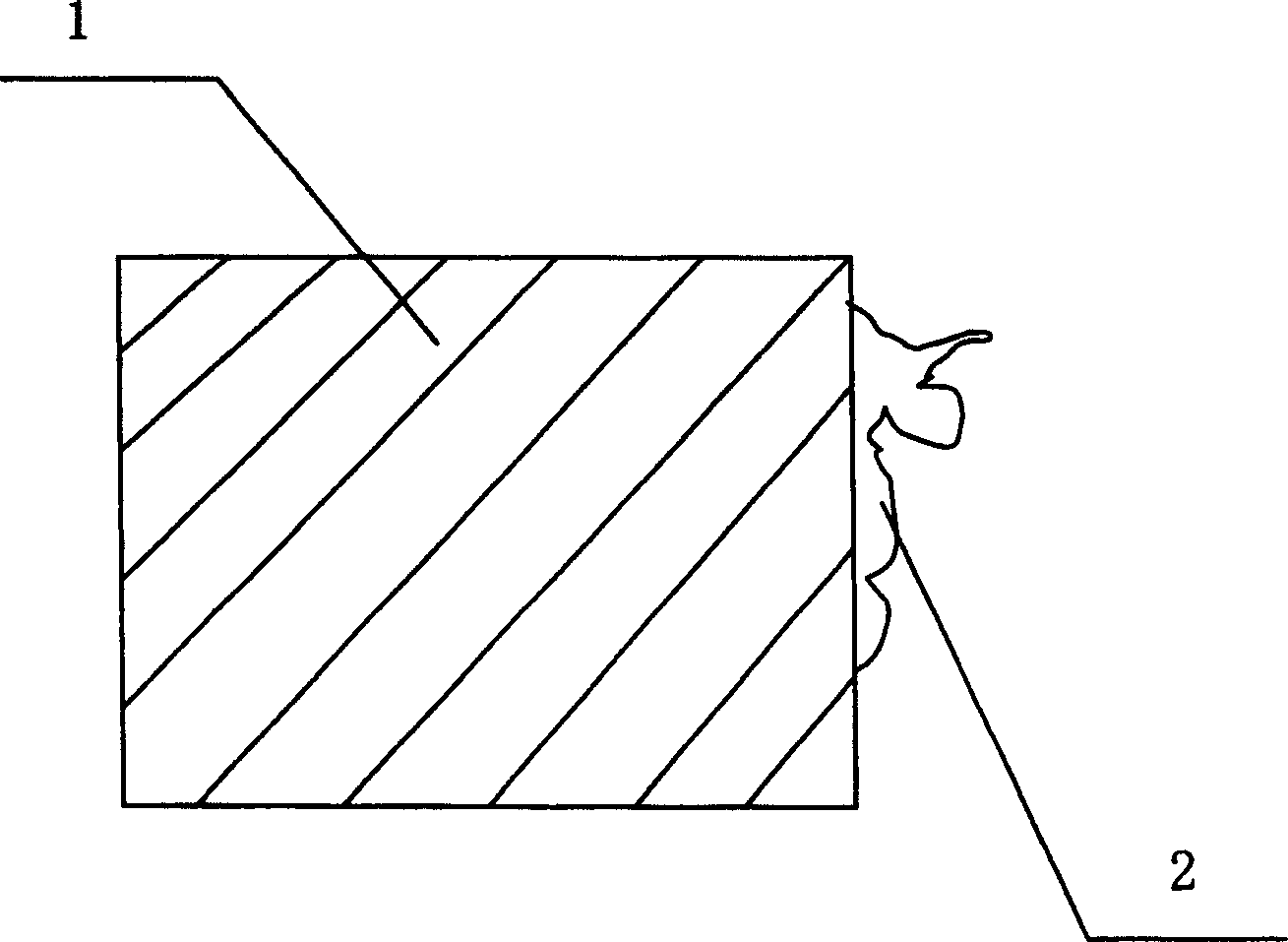

[0012] In the embodiment, the application of the present invention cuts off a 130×173mm square billet. Originally, the vertical cutting method was adopted. Due to the cutting lumps under the section of the billet, the billet in the steelmaking process is continuously cast for the cutting edge of the billet in the rolling process of the next process. Too much slag will cause a large number of head and tail cuts in the rolling process. In severe cases, the quality of the entire strip steel will be unqualified due to slag inclusions and pitting. Using the side cutting method of the present invention, the original cutting machine is slightly modified, and the flame cutting machine gun is changed to an "L" type cutting gun, which is convenient for side cutting, and the cutting position of the cutting gun is changed. The horizontal shift is changed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com