Device for mixing fluid

A technology for mixing fluids and fluids, which is applied in the direction of mixers, fluid mixers, gas and gas/steam mixing, etc. It can solve the problems of nozzle fuel cell function loss, nozzle clogging, nozzle efficiency reduction, etc., and improve operational safety. and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

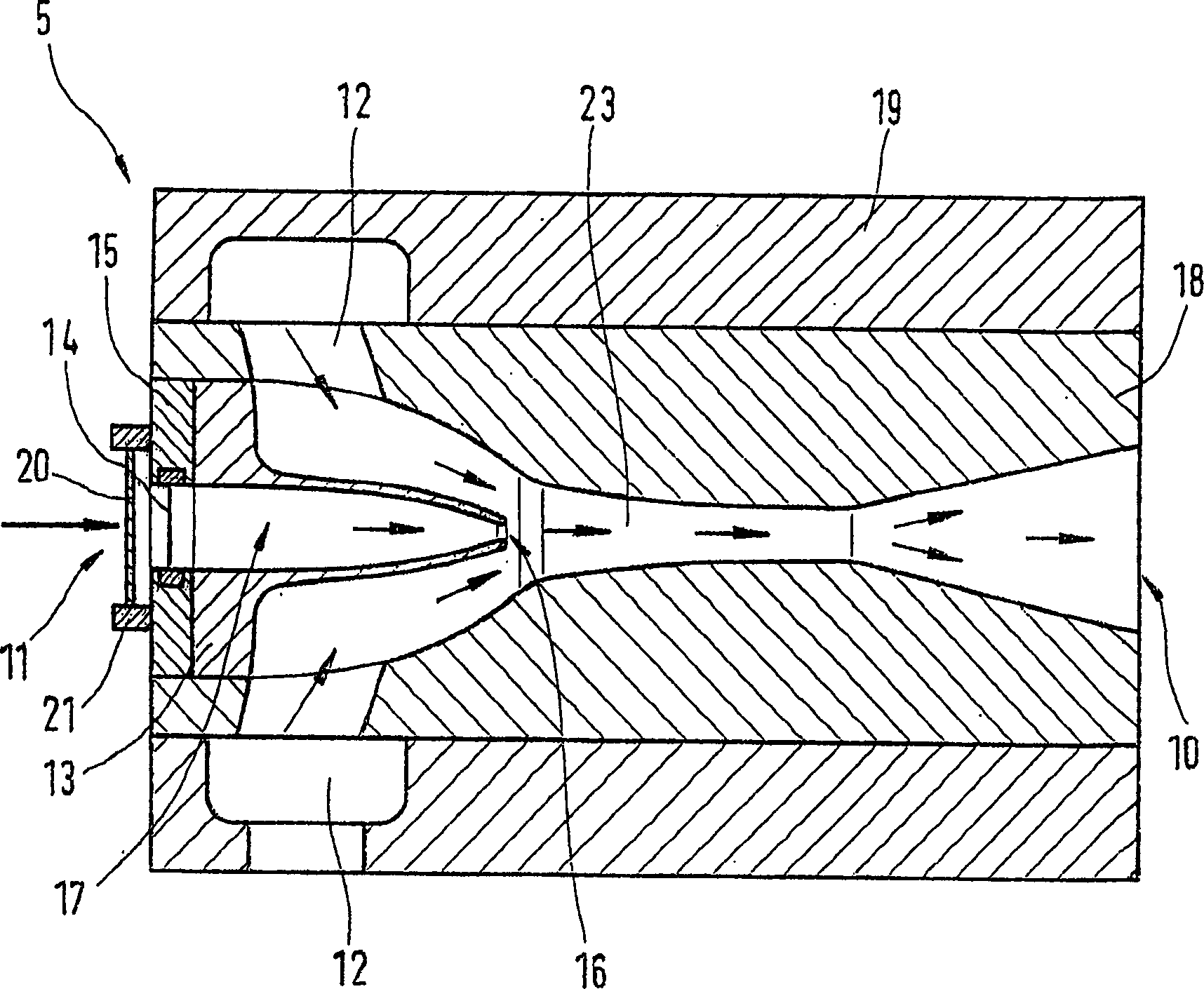

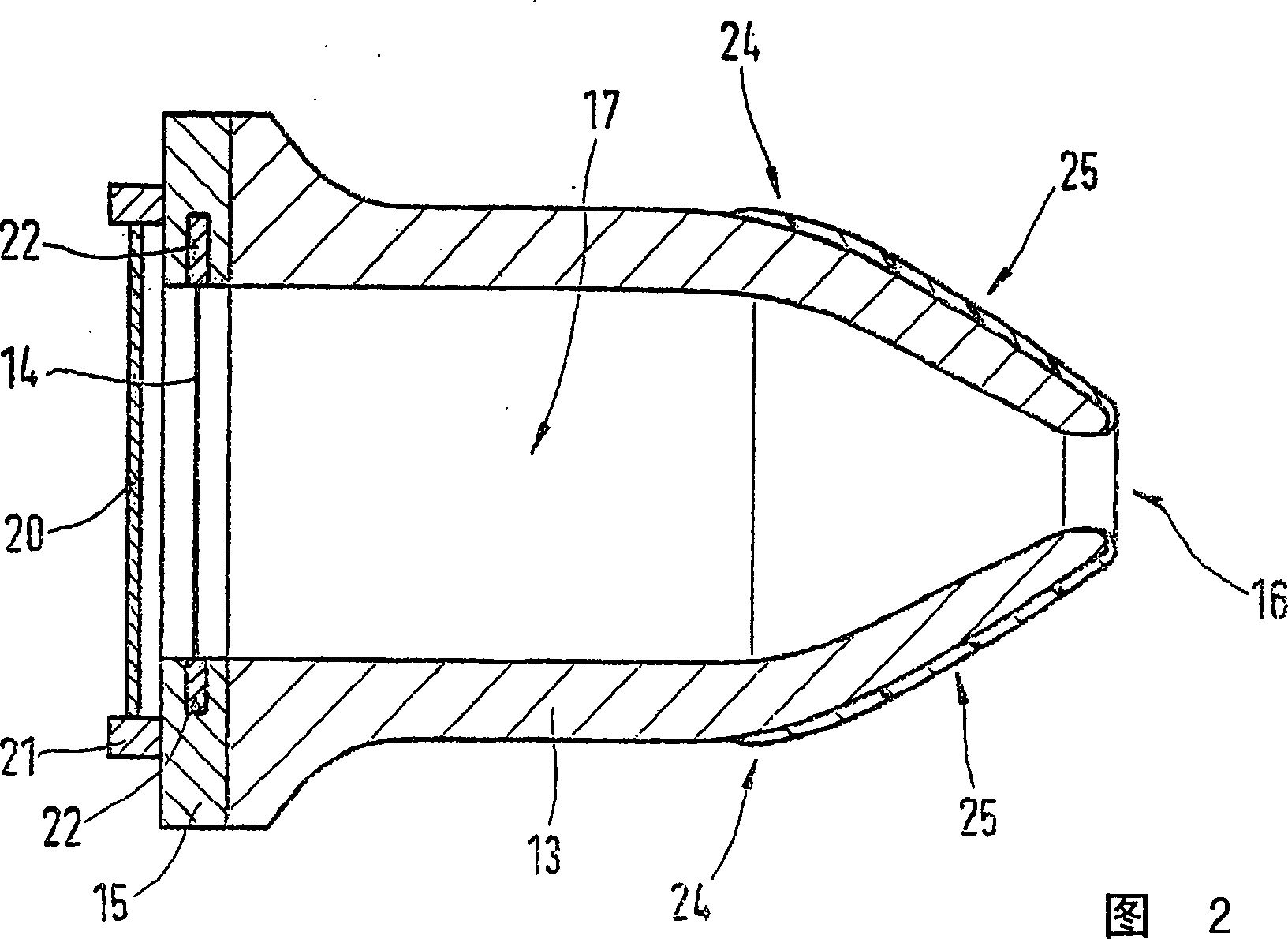

[0020] figure 1 A fluid mixing device 5 acting as a gas injection valve or mixing nozzle is shown. The fluid mixing device 5 is in particular a jet compressor nozzle, through which a strong, driving fluid carries a second, weaker fluid. For example, in the fluid mixing device 5 described, hydrogen and saturated water vapor are mixed with each other in a mixing tube or in a mixing zone inside the mixing device.

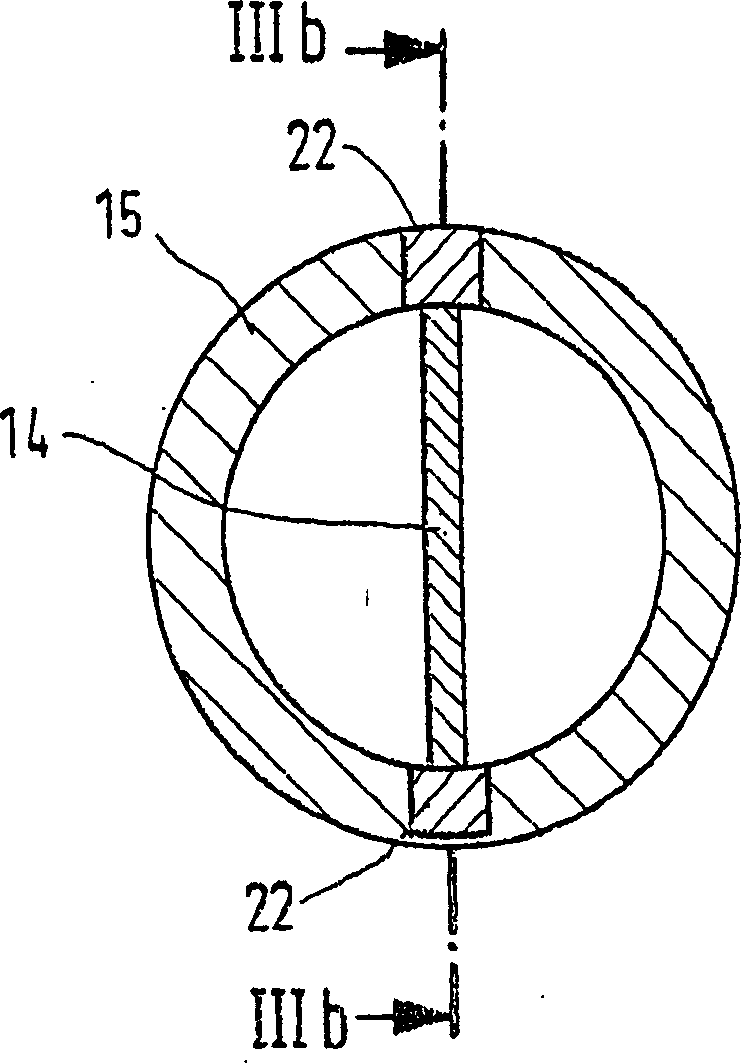

[0021] The fluid mixing device 5 additionally has a base body 18 which is surrounded by a sleeve 19 having an annular groove through which the first fluid, for example hydrogen or a gas containing hydrogen, can be supplied to the base body 18 . Furthermore, a funnel-shaped recess is provided in the base body 18 , which opens into a central duct 23 , which leads into a funnel-shaped opening 10 of the fluid mixing device 5 . Sleeve 19 or base body 18 according to figure 1 Preferably designed as a cylindrically symmetrical structure.

[0022] figure 1 Also shown, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com