Multilayer intumescent sheet

A technology of expansion sheet and expansion layer, which is applied to the above-mentioned device field equipped with flexible multi-layer expansion sheets, and can solve the problems of pollution control devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0140] 100 lbs (45.4 kg) of ceramic fiber (FIBERFRAX TM 7000M, available from Unifrax Co., Niagara Falls, NY) was slushed in 960 gallons (3,634 liters) of water for one minute. The fiber stock was then transferred to a 2,000 gallon (7,520 liter) stock chest and diluted with 140 gallon (526 liter) of water. While stirring, add 39 pounds (17.7kg) of 45.5% solid latex (RHOPLEX HA-8, available from ROHM & HAAS, Philadelphia, PA). 11 pounds (5.0 kg) of aluminum sulfate (50% solids) was then added to coagulate the latex. This latex-fiber paste is given the designation A below.

[0141] A second slurry was prepared as follows: 100 pounds (45.4 kg) of ceramic fiber (EIBERFRAX TM 7000M) was slurried in 960 gallons (3,634 liters) of water and mixed for 1 minute. Add 43 lbs (19.5 kg) of expanded vermiculite (ZONOLITE #5, available from W.R. Grace Co., Cambridge, MA) and mixed until dispersed. The fiber-expanded vermiculite slurry was pumped into a 1500 gallon (5,678 L) slurr...

Embodiment 6

[0144] 75 lbs (34.1 kg) of ceramic fiber (FIBERFRAX TM 7000M) was slurried in 400 gallons (1514 liters) of water for 90 seconds. It was then transferred to a 2,000-gallon (7,520-liter) pulp chest. Another 75 pounds (34.1kg) of ceramic fiber (FIBERFRAX TM 7000M) was slurried as above, transferred to the 2000 gallon (7570 liters) stock chest, and the combined stock was diluted with 250 gallons (946 liters) of fresh water. While stirring, add 22 pounds (10kg) latex (AIRFLEX TM 600BP, 55% solids), 3.3 pounds (1.5kg) liquid sodium aluminate (NALCO TM 2372, available from Nalco Chemical, Naperville, IL) and 3.1 ounces (0.09 liters) of antifoam (FOAMASTER TM III, available from Henkel Co., Edison, NJ). After 2-3 minutes, the pH of the mixture was measured to be 5.6. Next, 23 lbs (10.4 kg) of the aluminum sulfate (50% solids) solution was diluted with an equal volume of water and added to the slurry tank with stirring to form a slurry. This paste is given the reference C be...

Embodiment 7

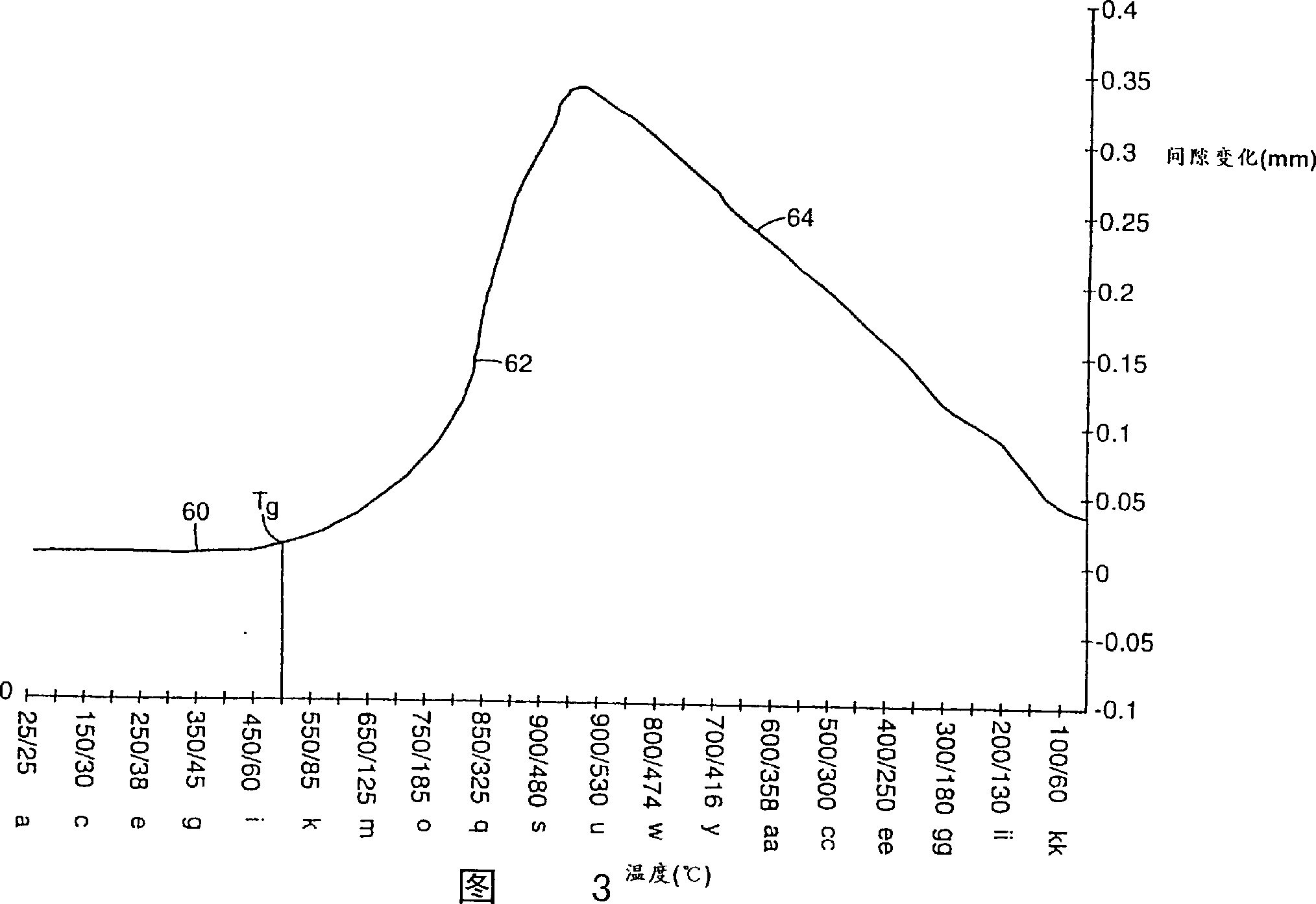

[0154] The settling pressure of the sample of Example 6 above and the sample of Comparative Example 1 below was tested and compared using the Real Condition Fixture Test (RCFT) described above. The temperatures used in the RCFT are representative of the temperatures measured in diesel catalytic converters. Comparative example 1 (C1) is a piece of 4070g / m 2 (nominal) single-layer, low-temperature expanded ceramic fiber sheet containing unexpanded vermiculite, which was purchased from 3M Company, USA under the designation INTERAM. The initial fixed density of embodiment 6 sample and C1 sample is respectively 0.9 and 1.0g / cm 3 .

[0155] The RCFT results of the Example 6 sample and the C1 sample are listed in Table 4 below. The test results show that the multilayer sheet of the present invention can provide higher pressure, ie fixing force, than the sheet of Comparative Example 1 within the indicated temperature range.

[0156] bulk temperature

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com