Ultra-high strength, weldable steels with excellent ultra-low temperature toughness

A technology of tensile strength and finish rolling temperature, applied in the field of weldable low-alloy pipeline steel and pipeline pipes, can solve the problems of not meeting the weldability requirements of pipeline pipes and lack of toughness of pipeline pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

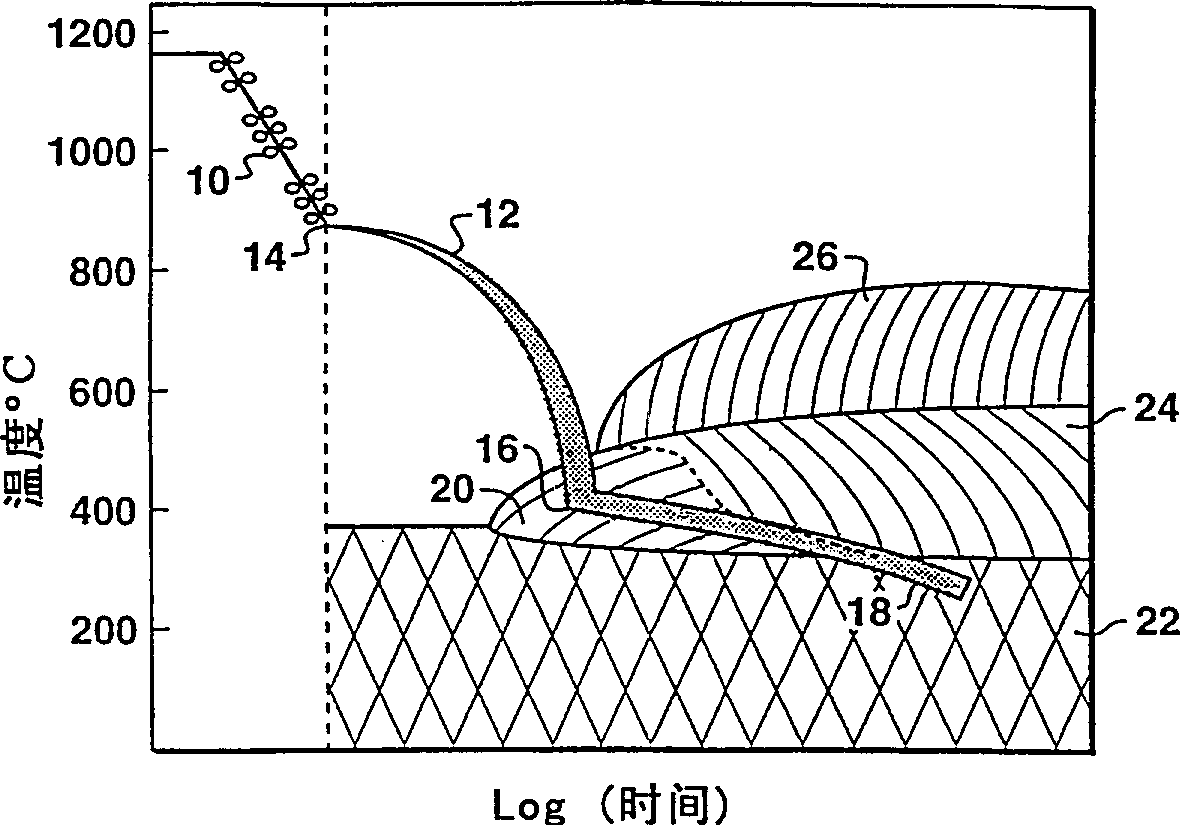

[0058]According to one aspect of the invention, a steel slab is treated by heating the slab to a substantially uniform temperature at which substantially all of the carbides and carbonitrides of vanadium and niobium are sufficiently dissolved, said temperature Preferably about 1000-1250°C (1832-2282°F), and more preferably about 1050-1150°C (1922-2102°F); The slab is hot-rolled for the first time, wherein the reduction is preferably about 20-60% (thickness direction), so as to be rolled into a plate through one or more passes; in the second temperature range, one or more In the pass, the second hot rolling is carried out with a reduction of preferably about 40-80% (thickness direction), the second temperature range is slightly lower than the first temperature range, and austenite cannot occur at this time recrystallized, but more than Ar 3 High transition point; hardening of the rolled plate by quenching with a cooling rate of at least about 10°C / sec (18°F / sec), preferably at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com