Slurry conveying equipment

A slurry conveying and equipment technology, which is applied in the field of loose material transportation devices, can solve the problems of reduced conveying efficiency, unstable operation, non-continuous slurry conveying, etc., and achieves the effect of high power and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

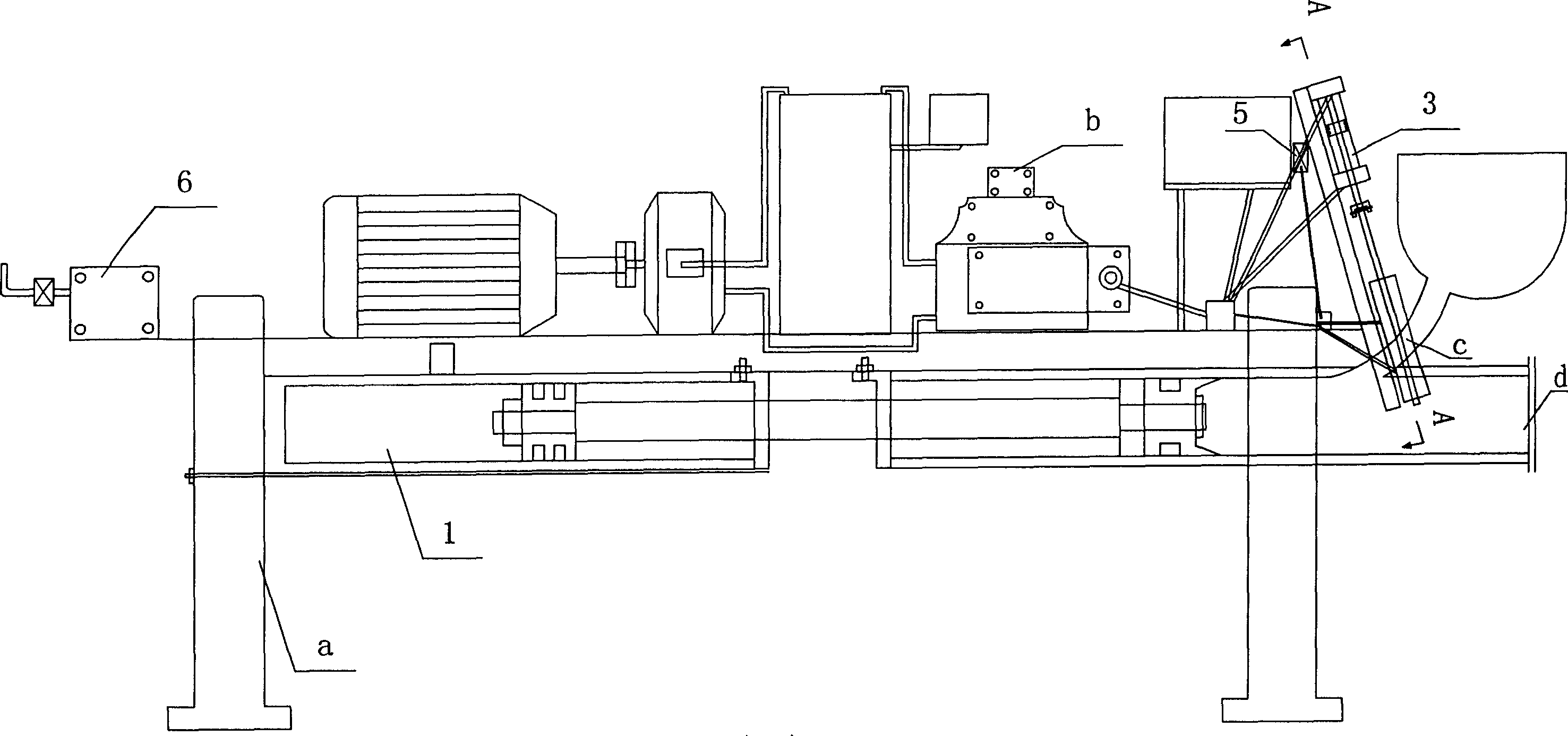

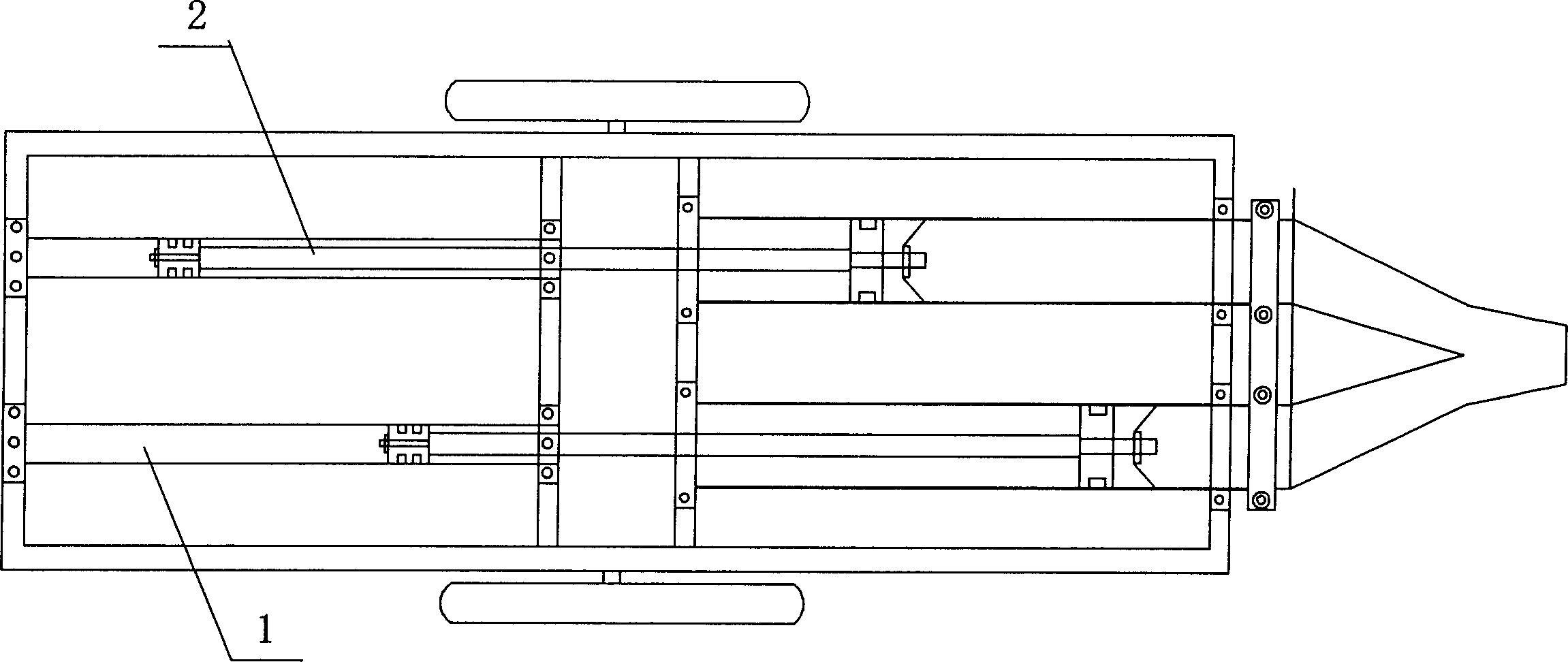

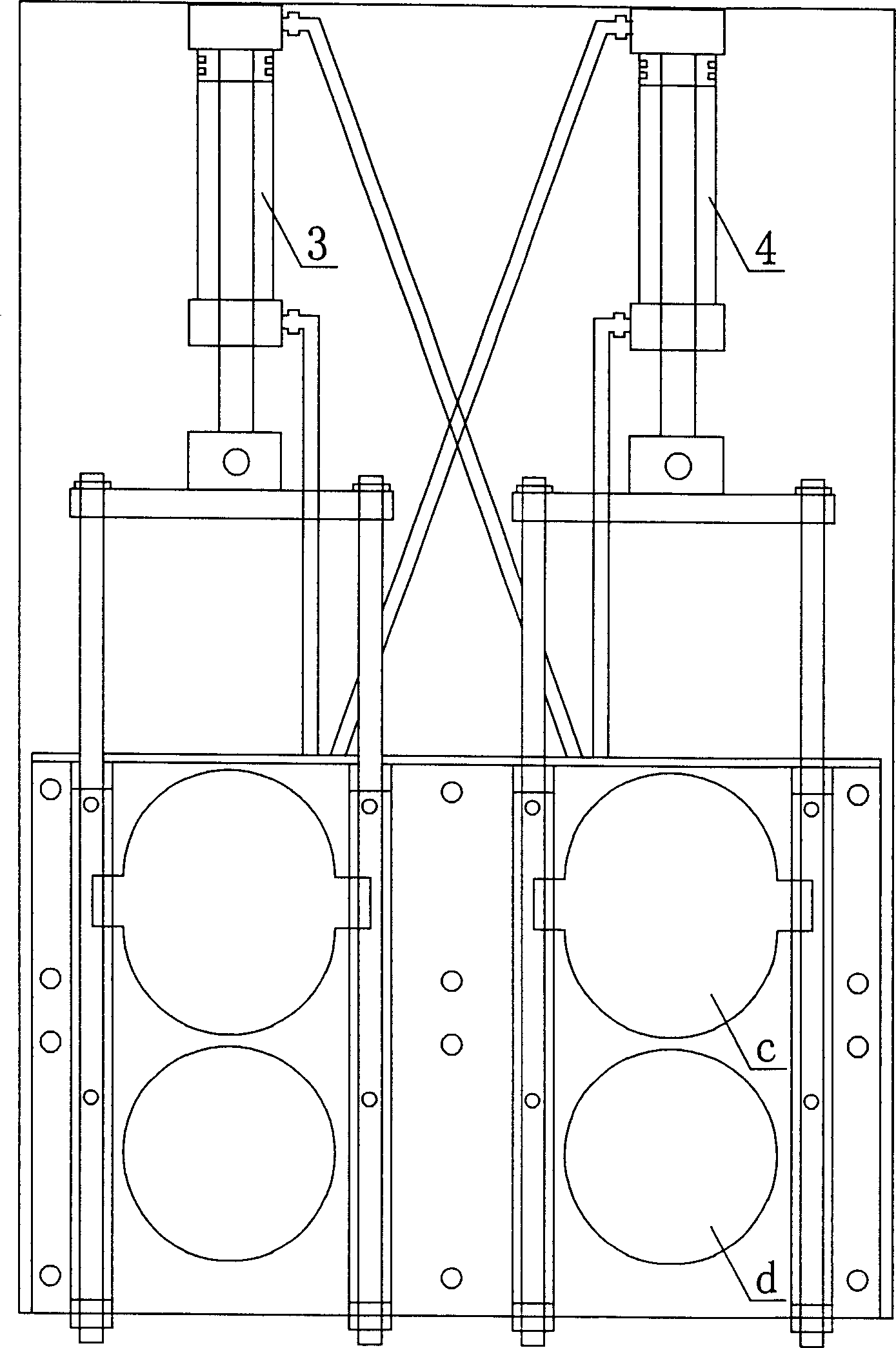

[0014] The invention comprises a frame a, two main hydraulic cylinders are installed on the frame a, a slurry cylinder is arranged in front of each main hydraulic cylinder, a piston is arranged in each hydraulic cylinder, and the free end of the piston rod is connected to the piston of the slurry cylinder , the front parts of the two slurry cylinders are provided with inlet c and outlet d, and the movement of the piston in the auxiliary hydraulic cylinder can open and close the inlet c and outlet d; the front oil of the first main hydraulic cylinder 1 port, the rear oil port of the second main hydraulic cylinder 2, the front oil port of the first auxiliary hydraulic cylinder 3, and the rear oil port of the second auxiliary hydraulic cylinder 4 are connected to an outlet of the reversing valve b, and the first main hydraulic cylinder 1 The rear oil port, the front oil port of the second master hydraulic cylinder 2, the rear oil port of the first auxiliary hydraulic cylinder 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com