Superhigh pressure dynamic pressure sensor

A dynamic pressure and sensor technology, applied in the direction of measuring blasting force, etc., to achieve the effect of high measurement pressure, improved dynamic response, and good dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

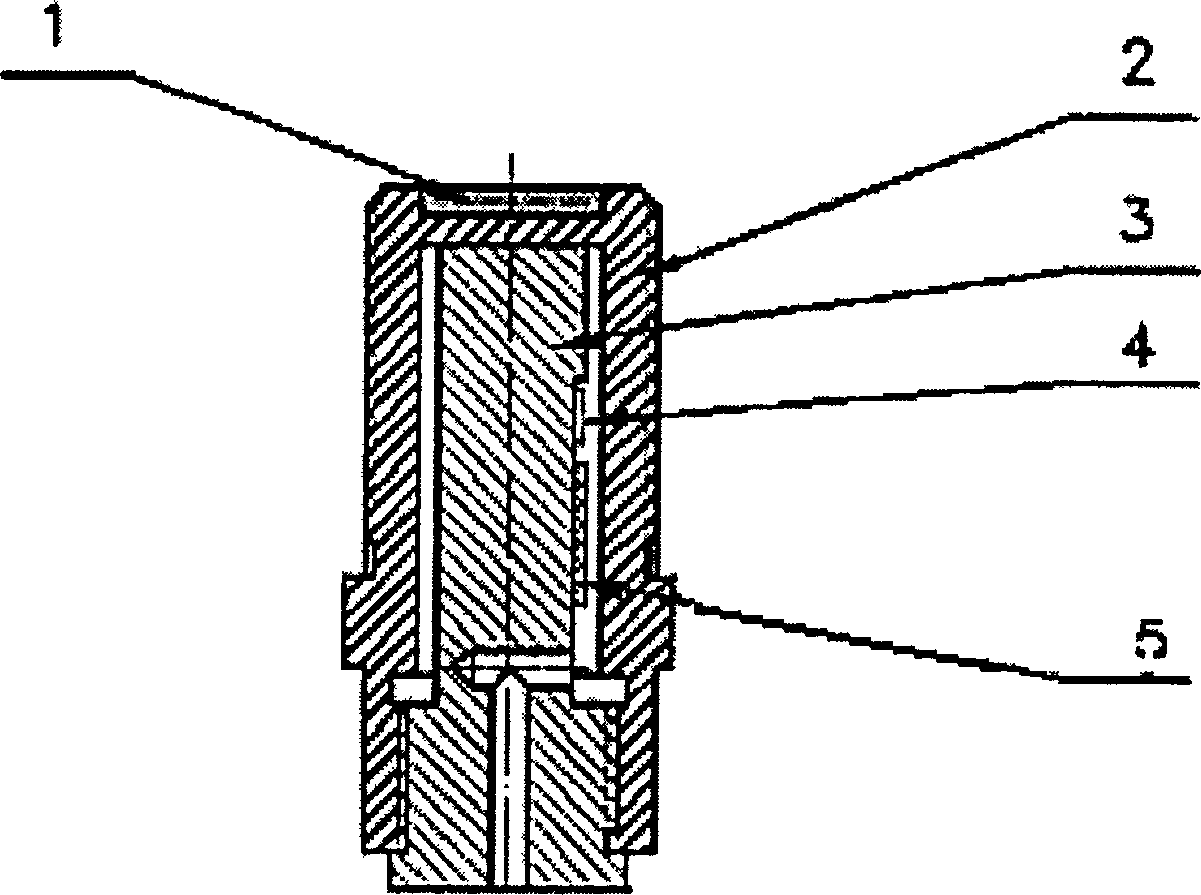

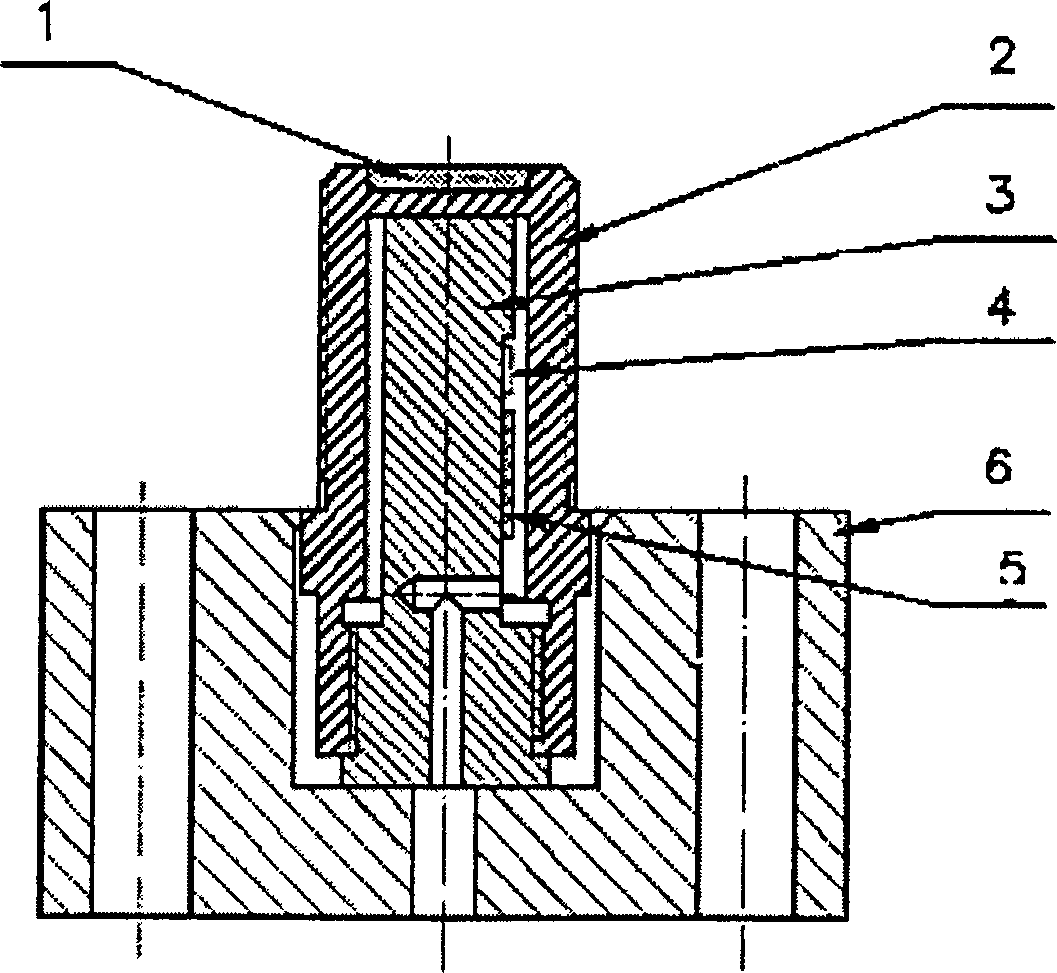

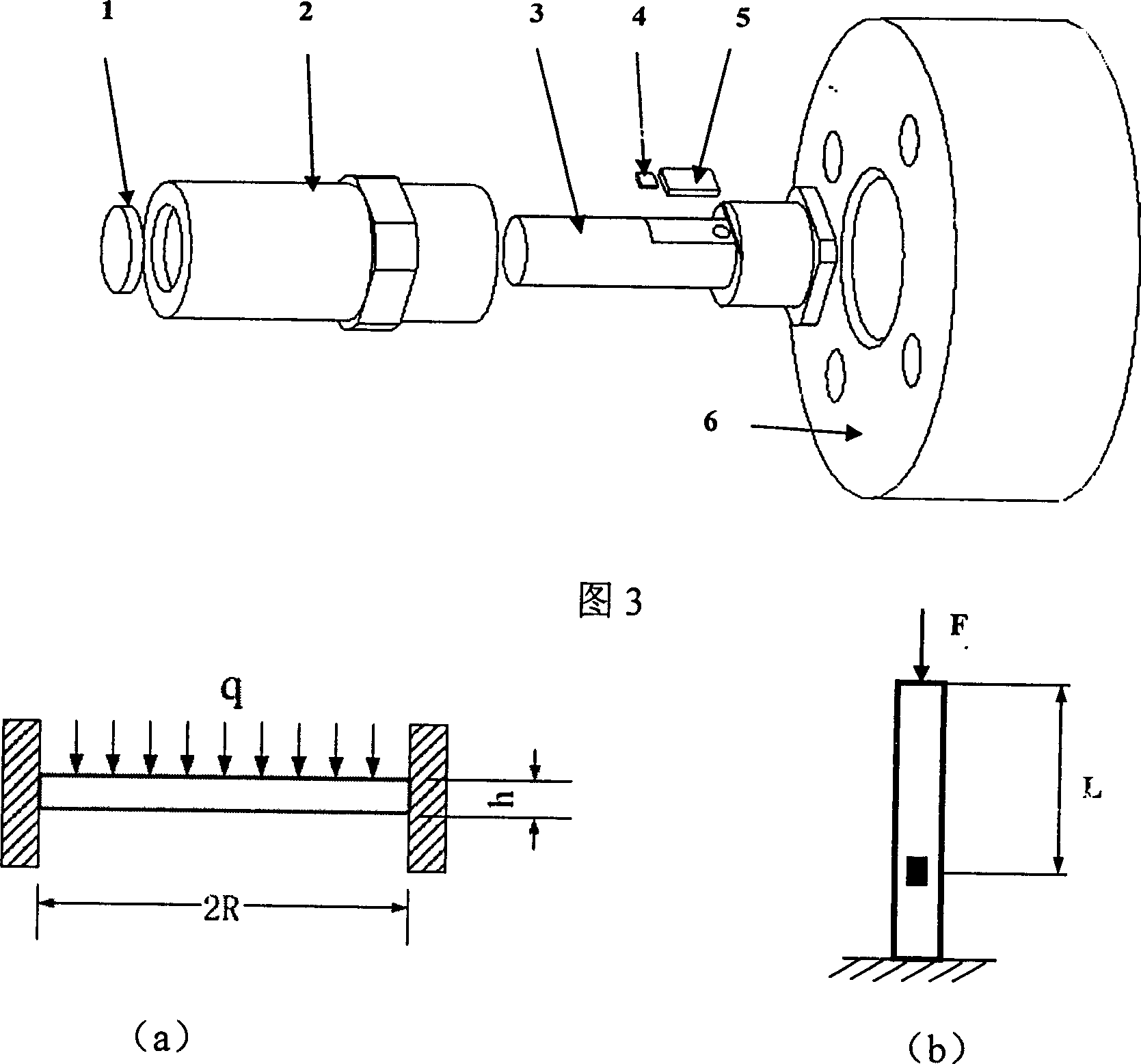

[0012] refer to figure 1 ~Fig. 3, the main ultra-high pressure dynamic pressure sensor of the present invention comprises shell 2, and the circumference of shell 2 has sensitive pressure-bearing diaphragm, and one end of shell 2 is equipped with strain cylinder 3 by screw thread, and in strain cylinder 3 has a platform, which is provided with SOI silicon micro-solid piezoresistive chip 4 and circuit board 5, SOI silicon micro-solid piezoresistive chip 4 is connected with circuit board 5 through gold wire, and the lead wire on the circuit board 5 passes through the circuit board 5 on the platform. A hole passes through the bottom of the strain cylinder 3 , and a replaceable gasket 1 is provided at the other end of the casing 2 , and the replaceable gasket 1 is connected with a sensitive pressure-bearing diaphragm on the circumference of the casing 2 .

[0013] Considering that the pressure on the sensor is very high, another pressure plate 6 is used to fix the sensor on the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com