Squeeze film damper for rolling bearing turbochargers

A squeeze oil film damping and turbocharger technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as large vibration of the rotor system, short service life of the turbocharger, unstable operation, etc., to achieve Effects of improving life and reliability and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

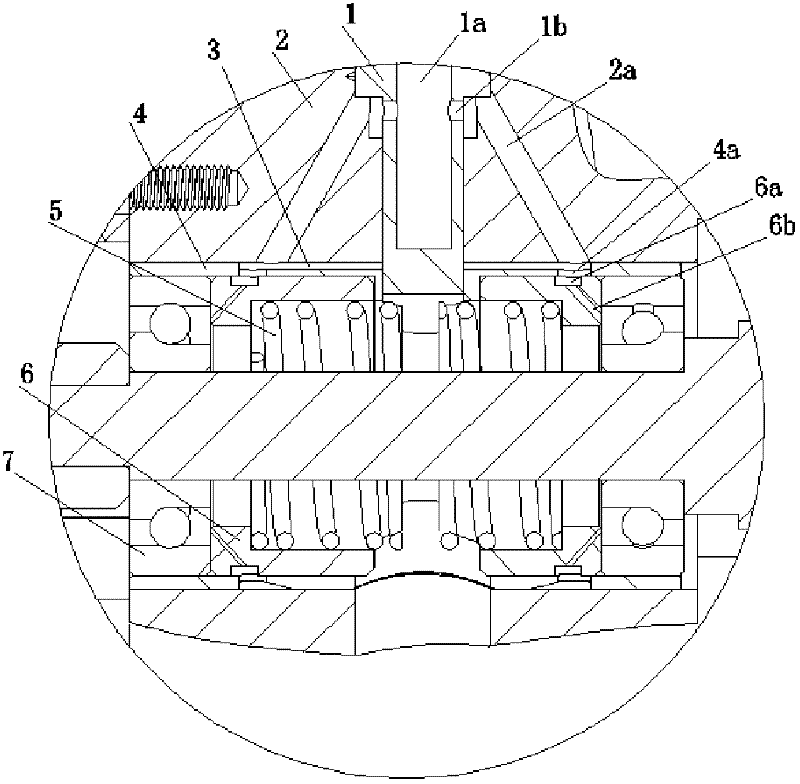

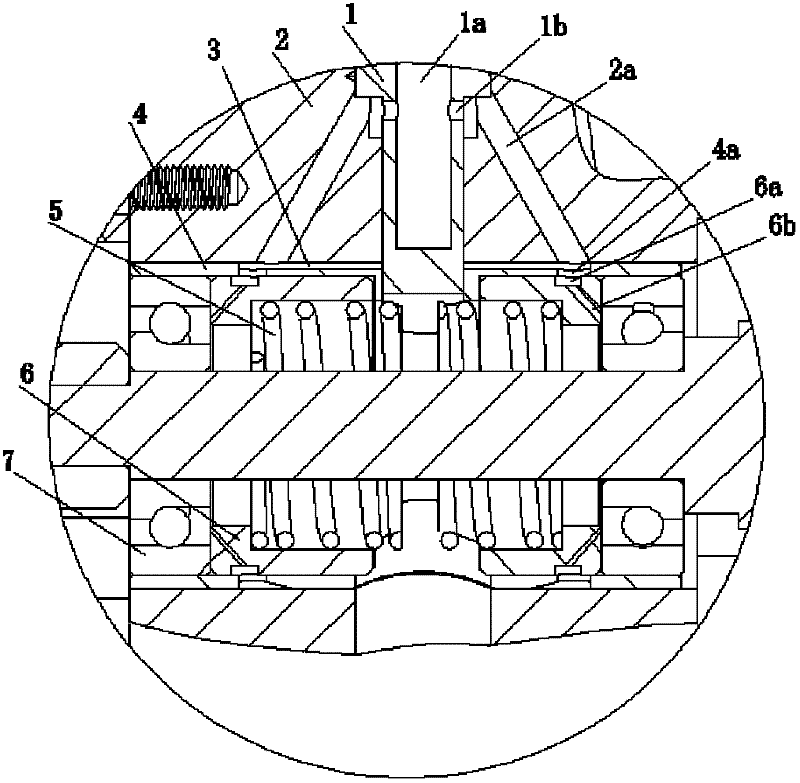

[0016] This embodiment is as figure 1 As shown, the squeeze film damper of a rolling bearing turbocharger includes lubricating oil, an intermediate body 2, a positioning pin 1, and a bearing sleeve 4 in the rotor system, and the bearing sleeve 4 is fixed inside the intermediate body 2 by the positioning pin 1 On the hole, when the bearing sleeve 4 is fixed with the positioning pin 1, there is a gap 3 between the bearing sleeve and the intermediate body. The inside of the positioning pin 1 is hollow, and the hollow part is used as the lubricating oil main channel 1a, and the intermediate body 2 There is a lubricating oil branch 2a, the lubricating oil main channel 1a communicates with the lubricating oil branch 2a through the outlet hole 1b on the side wall of the positioning pin 1, the lubricating oil branch 2a communicates with the gap 3, and the lubricating oil is pressure lubricating oil. The pressure lubricating oil enters the gap 3 from the lubricating oil main channel 1a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com