New dry process cement production line control system

A dry-process cement and control system technology, applied in the direction of comprehensive factory control, electrical program control, etc., can solve the problems of large fluctuations in the level of shift operation, troubled production and operation managers, difficult to unify and standardize operating methods, etc., to improve control. Adaptability and stability, solving hysteresis and hysteresis, and improving the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

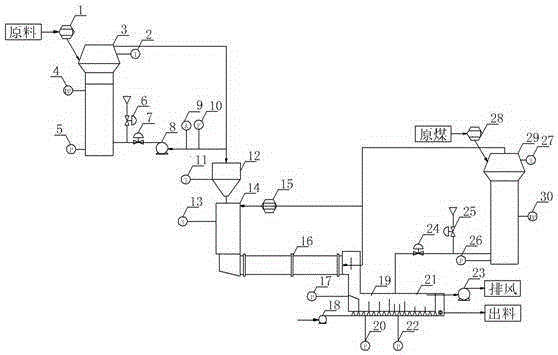

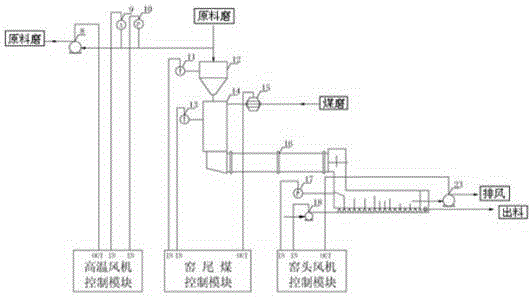

[0015] The control system of the present invention is composed of four parts: a raw material mill control unit, a firing control unit, a grate speed control unit, and a coal mill control unit. Among them, the raw material mill control unit is composed of the raw material mill feeding control module and the raw material cold and hot air valve control module; the firing control unit is composed of the high temperature fan control module, the kiln tailing coal control module, and the kiln head fan control module; the grate speed control unit The segmented grate speed control module is adopted; the coal mill control unit is composed of a coal mill cold and hot air valve control module and a mill coal feed control module.

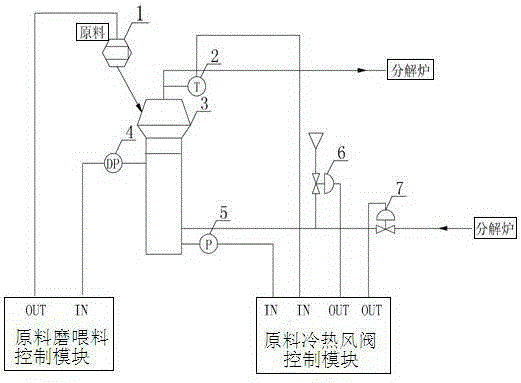

[0016] 1. Raw material mill control unit

[0017] like figure 2 As shown, the raw material mill control unit is composed of a raw material cold and hot air valve control module and a raw material mill feeding control module.

[0018] 1. Cold and hot air val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com