Method for making black matrix and colorful filter

A technology of color filter and manufacturing method, applied in optics, optical elements, nonlinear optics, etc., can solve the problem of inability to increase the aperture ratio, and achieve the increase of the complexity of the manufacturing process, the improvement of chromaticity and brightness, and the reduction of line width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

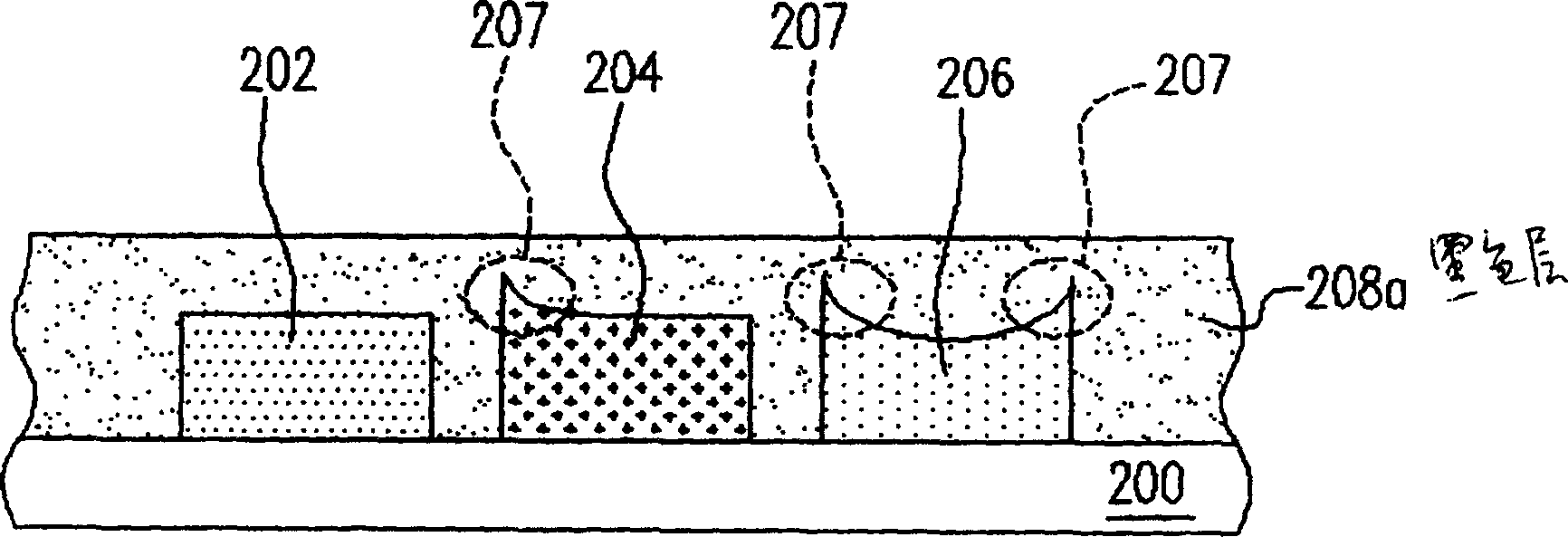

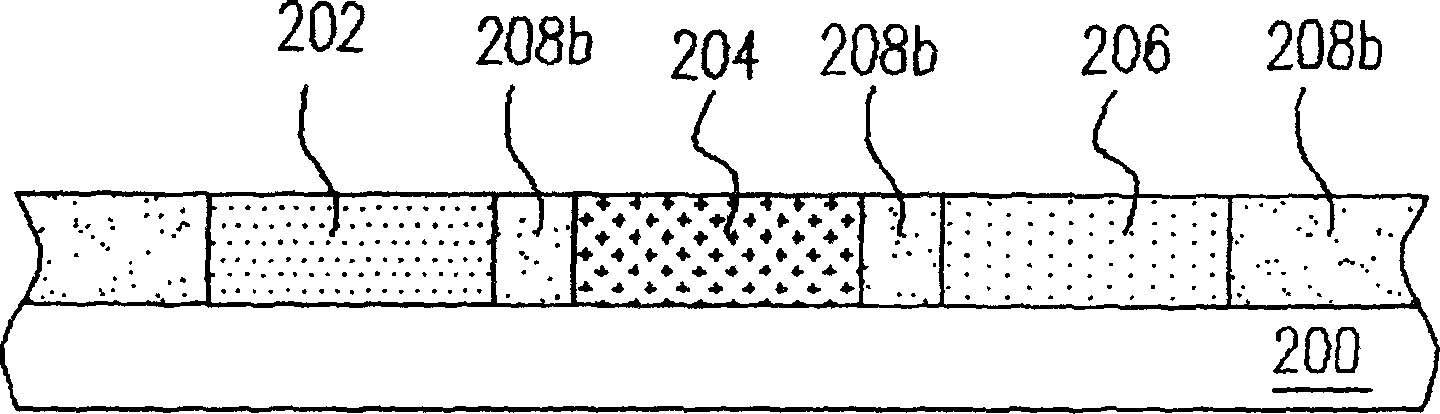

[0027] When the present invention is applied to the production of color filters, please see Figure 2A to Figure 2C Shown. Although there are only three color blocks in the figure, in fact, the color filter has a large number of color blocks, and its configuration is also divided into mosaic type, stripe type, four-pixel configuration type or triangle type, etc. Therefore, the present invention does not Limited to any specific type of color filter

[0028] Figure 2A to Figure 2C It is a schematic cross-sectional view of a color filter manufacturing process according to a preferred embodiment of the present invention. Please refer to Figure 2A First, a transparent substrate 200 such as a glass substrate is provided, and then a red (red) color block 202, a green (green) color block 204, and a blue (blue) color block 206 are formed on the transparent substrate 200, respectively. Before forming the red, green, and blue color blocks, a cleaning step, such as a brush manufacturing pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com