Apparatus and method for writing curve servo sector image

A sector and curve technology, applied in the field of media master production, which can solve problems such as output and multiple memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

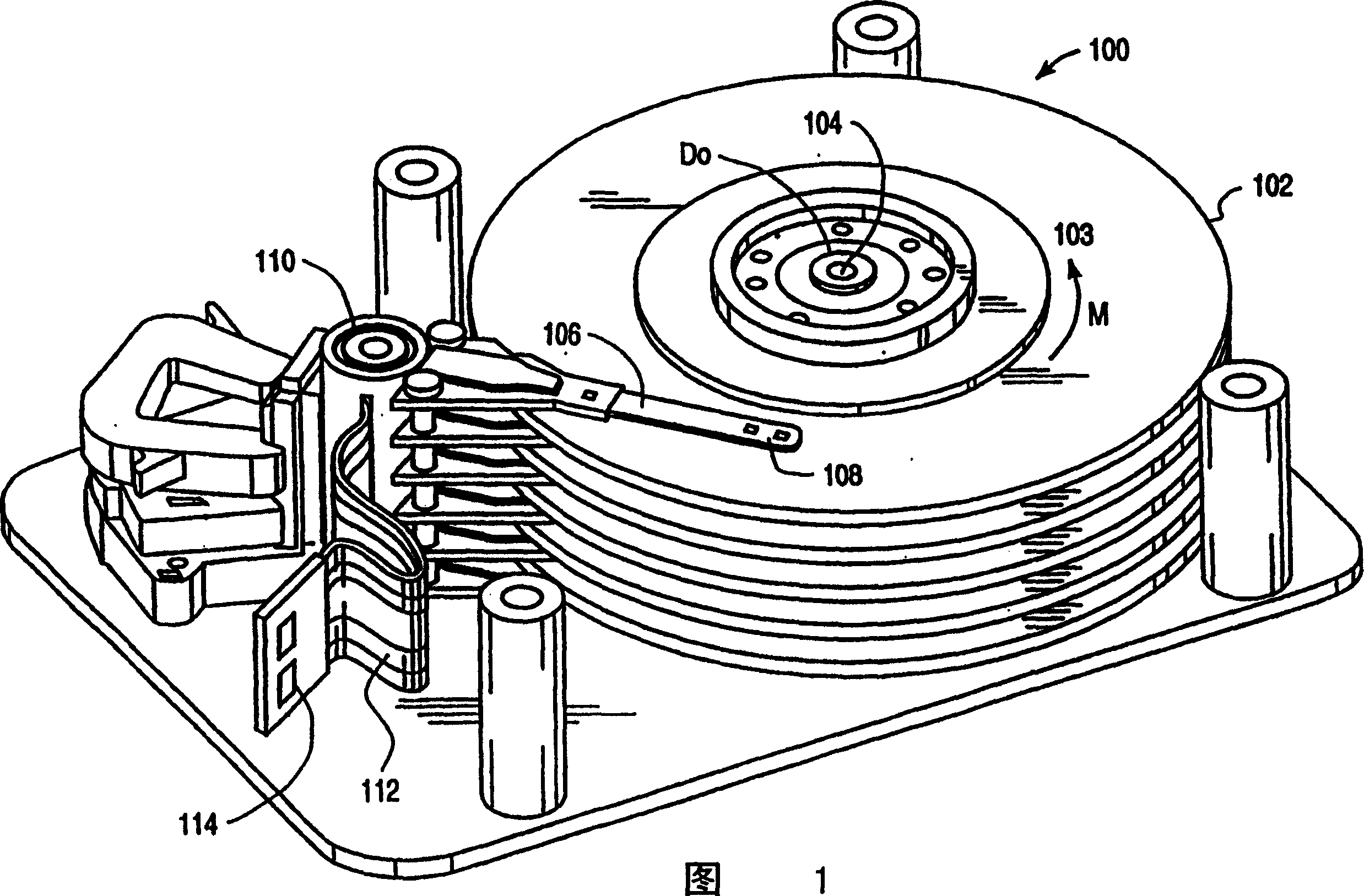

[0030] Referring now to the block diagram in FIG. 1 , an exemplary data storage disk system 100 includes a plurality of disks 102 mounted on a drive spindle 104 extending through a central hole D in the disks. 0 . Disk 102 rotates in a counterclockwise direction (as indicated by arrow M) at a speed measured in revolutions per minute. An actuator arm 106 at one end carries a suspended read / write head 108 over the surface 103 of a selected disk 102 . Although the read-write head 108 is shown positioned above the upper surface of the uppermost disk in the stack, it should be understood that the read-write head 108 may also reside on the upper and lower surfaces of any number of disks 102 . The opposite end of the actuator arm 106 is connected to a rotary actuator assembly 110 configured to rotate the actuator arm 106 so that the read / write head 108 pivots. The data pulse signal is received from the associated disk surface 103 and transmitted in a conventional manner along the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com