Attrition mill

A refiner and grinding disc technology, which is applied in pulp beating/refining method, textile and papermaking, fiber raw material processing, etc., can solve the problems of non-sizing of tooth surface, decrease in tensile strength, increase in pressure, etc., and reach the point of failure less, reduce the loss of fiber, reduce the effect of unit pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

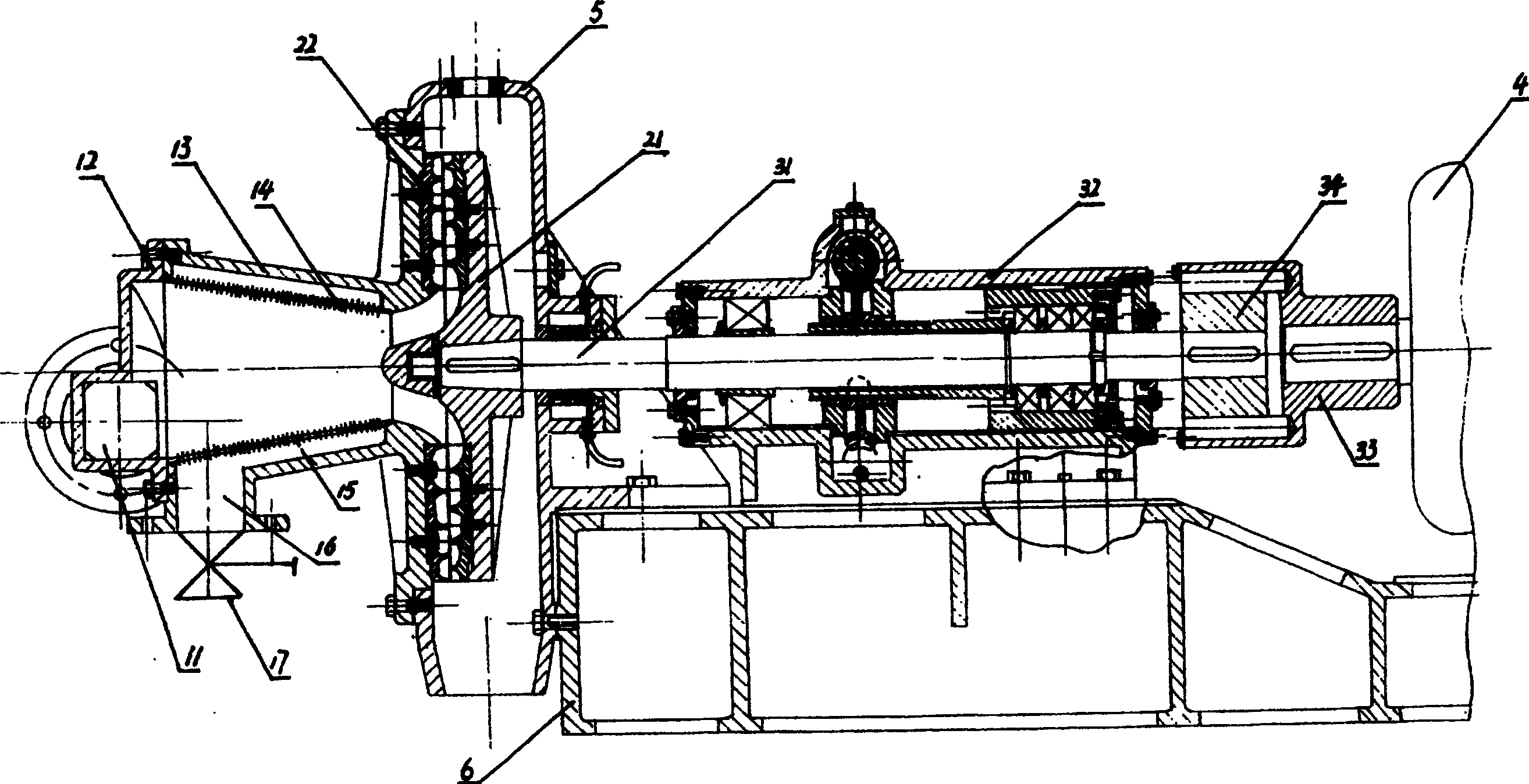

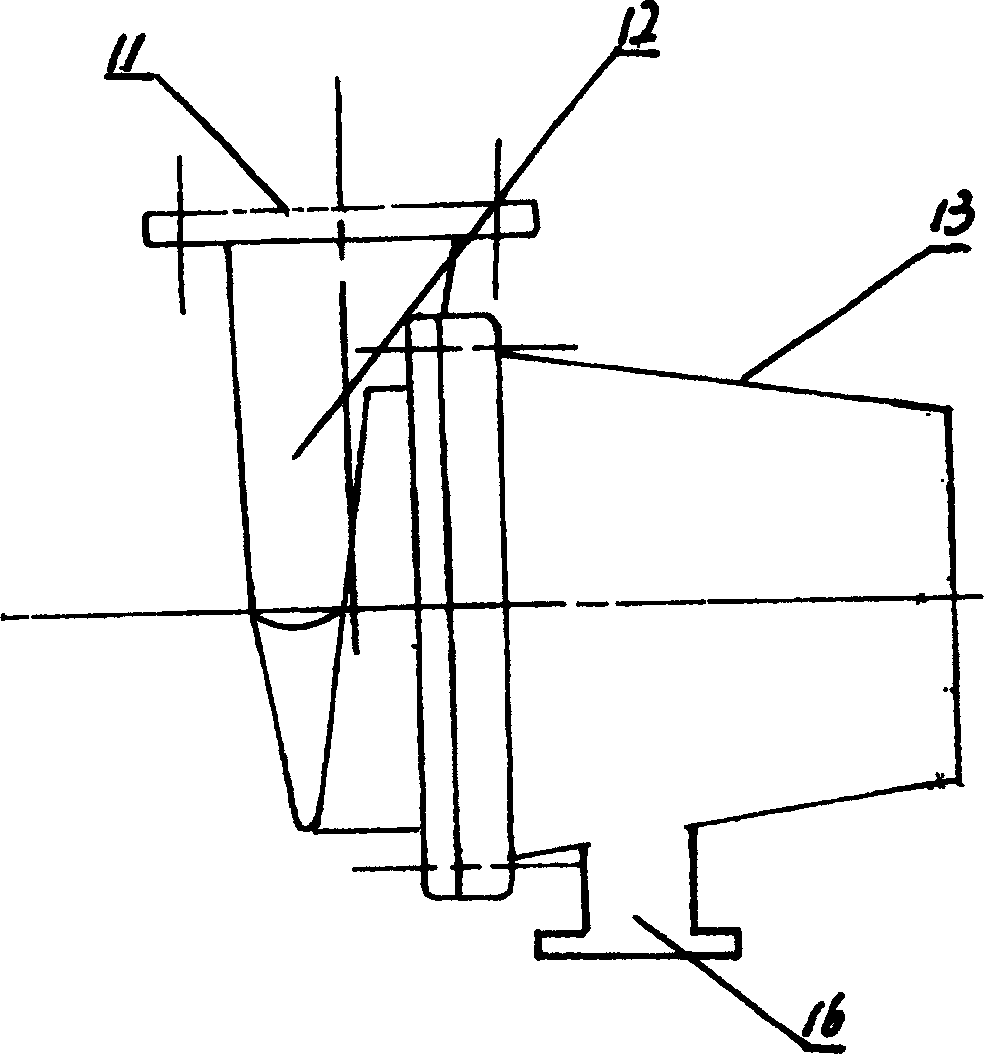

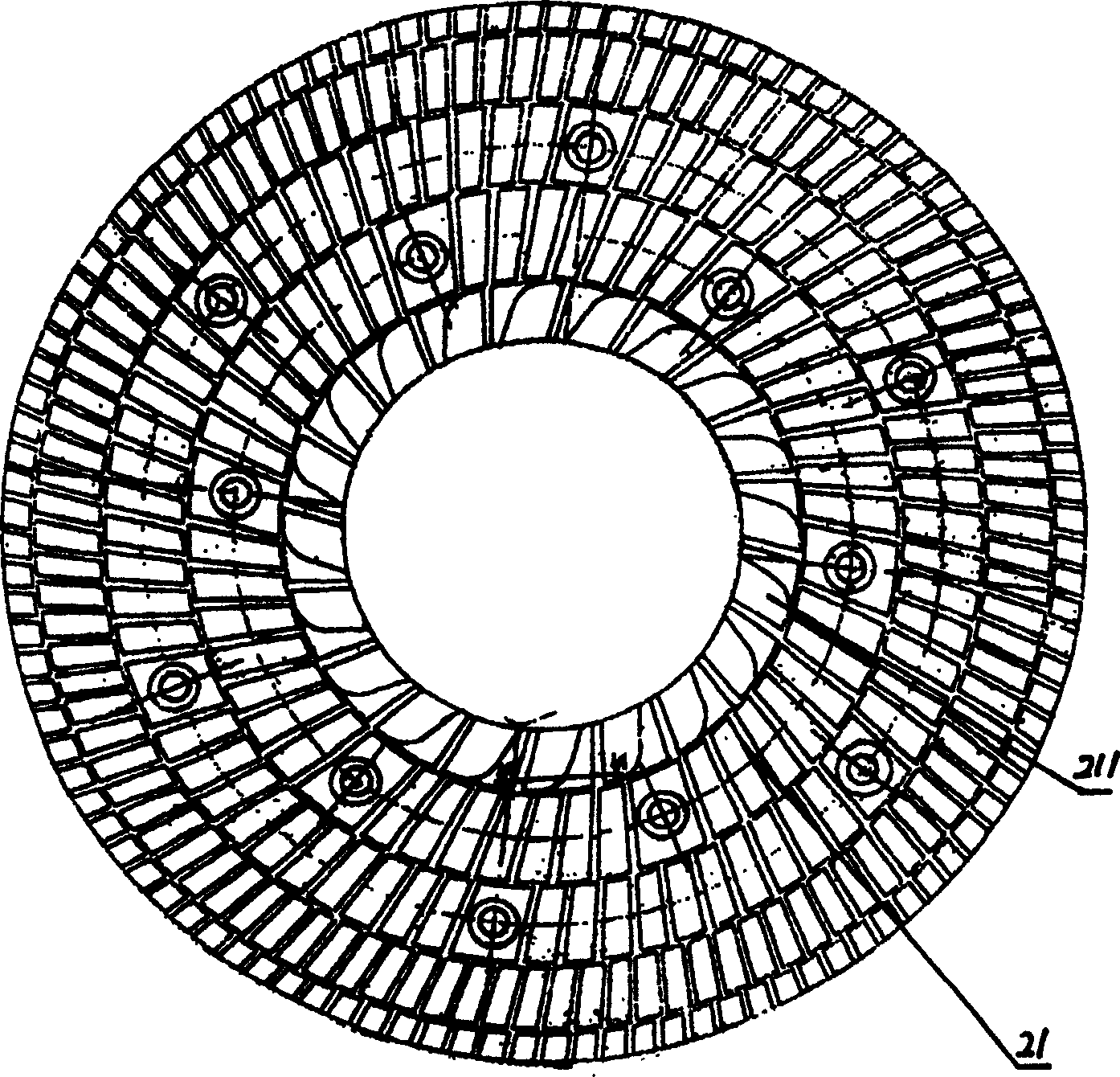

[0028] like figure 1 As shown, a kind of refiner of the present invention, it comprises milling disc part, transmission part and electric motor in turn and is formed, and milling disc part is installed in the casing 5 with screws, and casing 5 and transmission part are all installed in machine base with screws 6; the grinding disc part includes a rotating grinding disc 1 and a fixed grinding disc 2 matched with the rotating grinding disc 1. The rotating grinding disc 1 is installed on the main shaft 31 of the transmission part, and the fixed grinding disc 2 is installed on the inner wall of the casing 5. The transmission part mainly includes the main shaft 31 , bearing housing 32, driving coupling 33 and driven coupling 34, driven coupling 34 is installed on the main shaft 31, driven coupling 34 is sleeved in driving coupling 33, driving coupling 33 links to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com