Circuit structure for connecting weld-pad and electrostatic protective circuit

A technology of electrostatic discharge protection and circuit structure, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of unfavorable component integration, reduced process margin, etc., achieve large variability and freedom, enhance protection ability, Avoid the effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

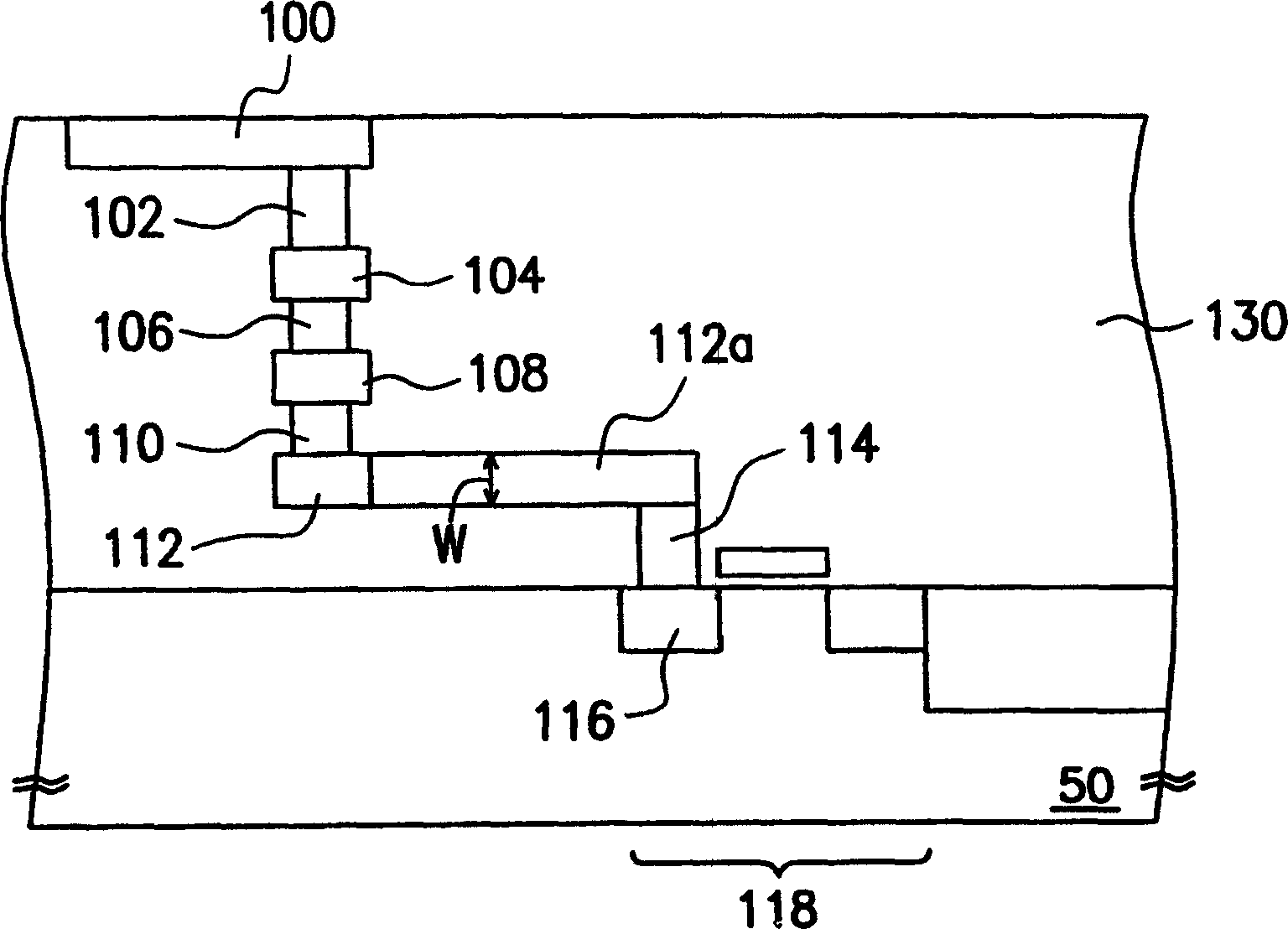

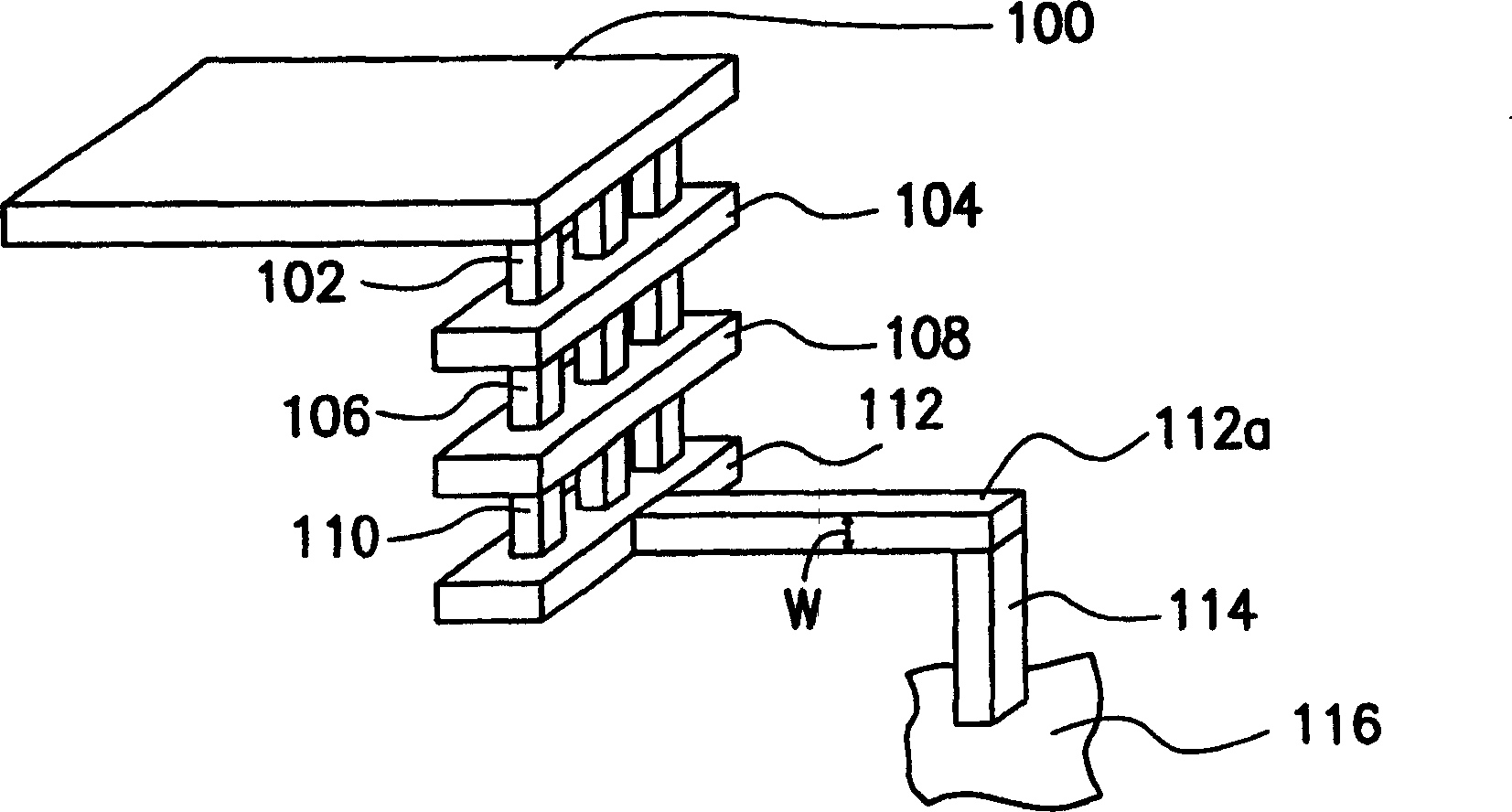

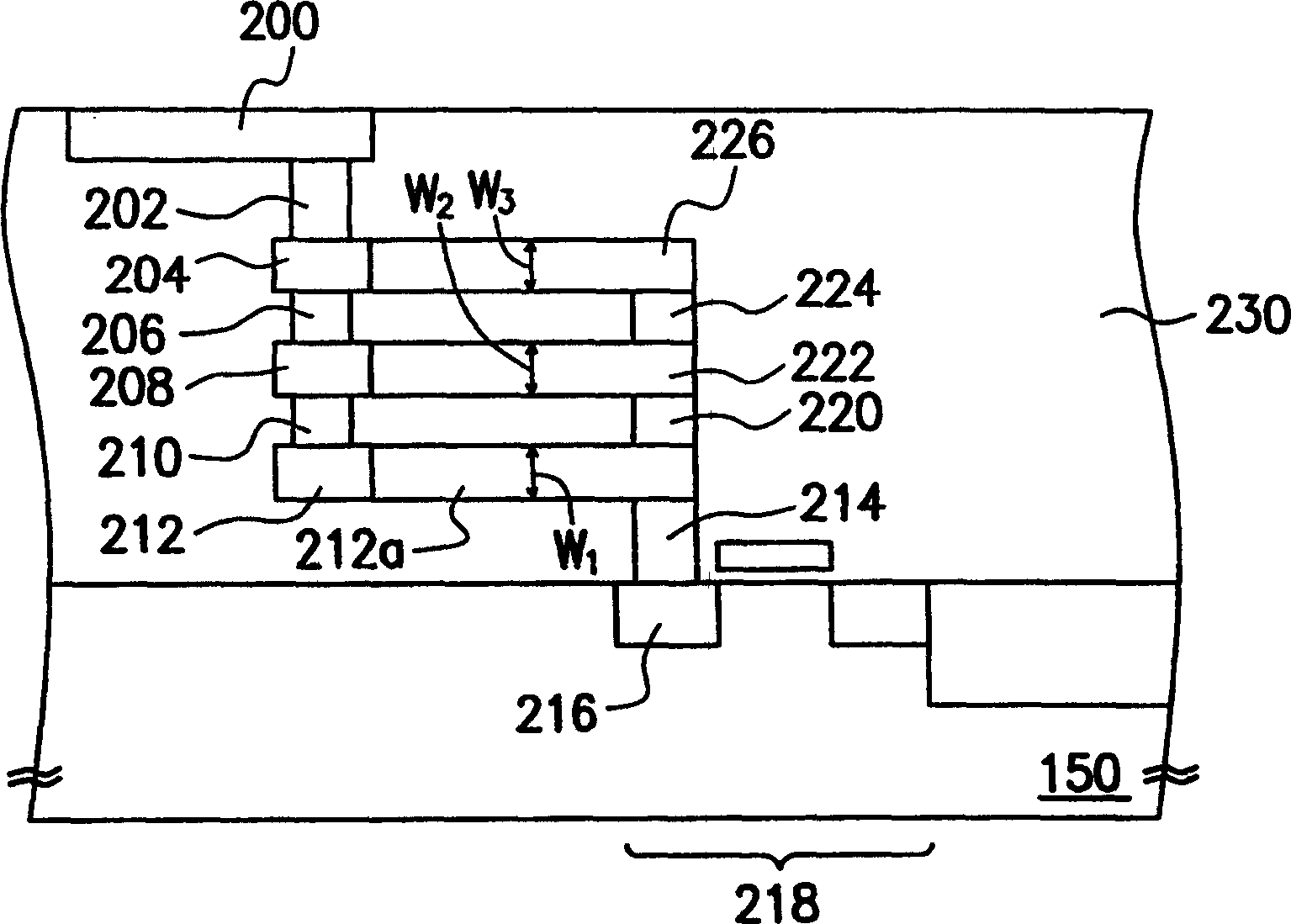

[0027] image 3 It is a cross-sectional view of the circuit connection between the solder pad of the semiconductor element and the electrostatic discharge protection circuit according to the preferred embodiment of the present invention, and Figure 4 It is a perspective view of the circuit connection between the solder pad of the semiconductor element and the electrostatic discharge protection circuit according to the preferred embodiment of the present invention.

[0028] Please also refer to image 3 and Figure 4 . The external circuit structure of the connection pad 200 and the electrostatic discharge protection circuit 218 of the present invention includes: a via 202, a conductive layer 204, a via 206, a conductive layer 208, a via 210, a conductive layer 212, and as an extension wire The wire 212a, the contact 214, the via 220, the wire 222 as a dummy wire, the via 224, and the wire 226 as a dummy wire.

[0029] exist image 3 and Figure 4 Among them, the bonding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com