Film filter

A membrane filtration and membrane module technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of reducing filtration capacity, reducing effective working time, reducing the life of membrane modules, etc., and achieving a reduction in filtration capacity. The effect of delaying, increasing effective working time and improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

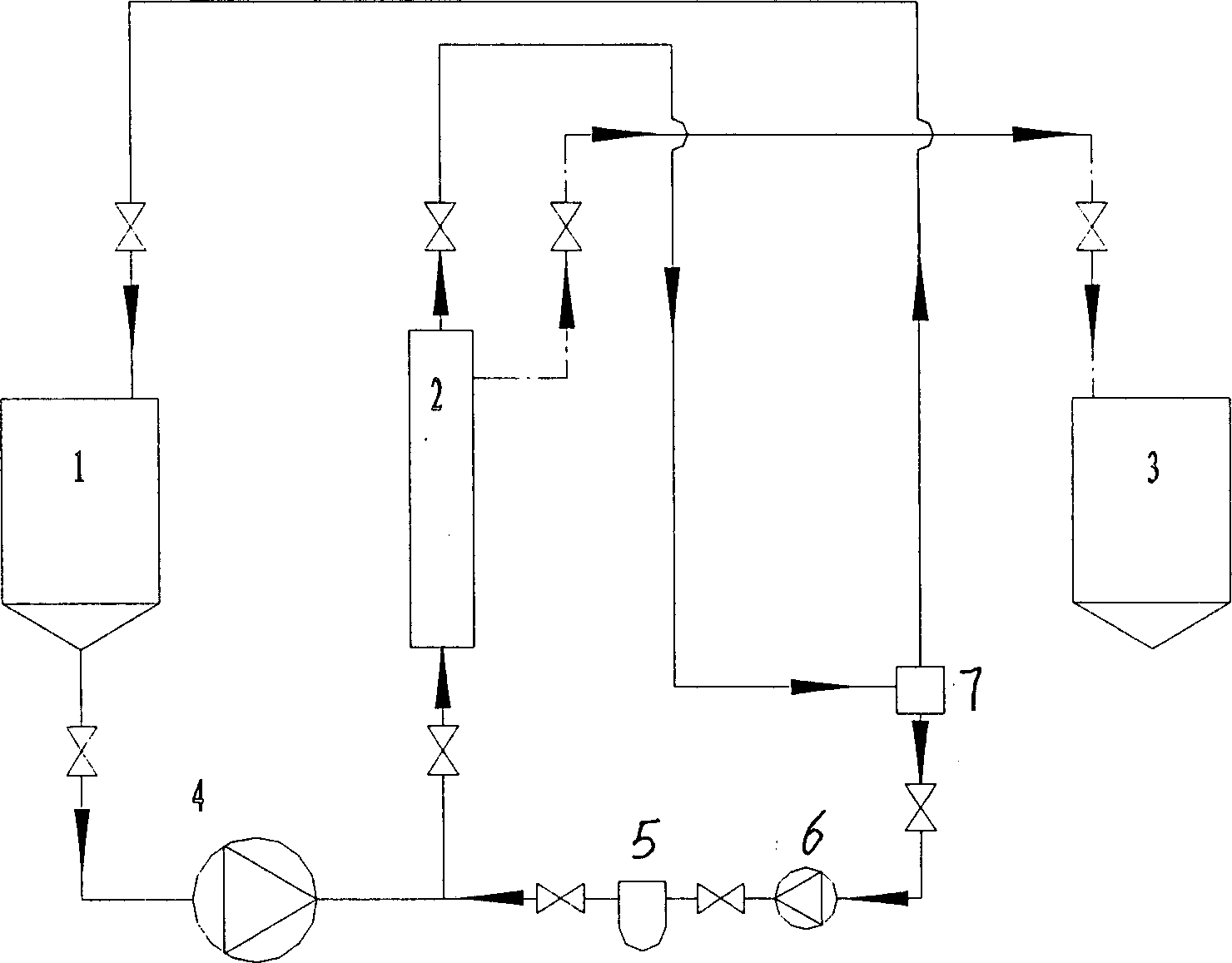

[0028] A membrane filtration device according to the present invention comprises a stock solution tank 1, a membrane module 2, a net liquid tank 3 and a stock solution pump 4, the stock solution tank 1 is connected to the inlet of the membrane module 2 through the stock solution pump 4, and an outlet of the membrane module 2 It is connected with the net liquid tank 3, the inlet of the membrane module 2 is connected with the ball tank 5, and the other outlet of the membrane module 2 is connected with the ball liquid separator 7, and the ball tank 5 is connected with the ball liquid through the ball pump 6. The separator 7 is connected, and the other end of the ball liquid separator 7 is connected with the stock solution tank 1 .

[0029] During work, at first load an appropriate amount of regenerated balls into ball groove 5, the regenerated balls can be rubber balls. The stock solution is fed into the membrane module 2 from the stock solution tank 1 by the stock solution pump ...

Embodiment 2

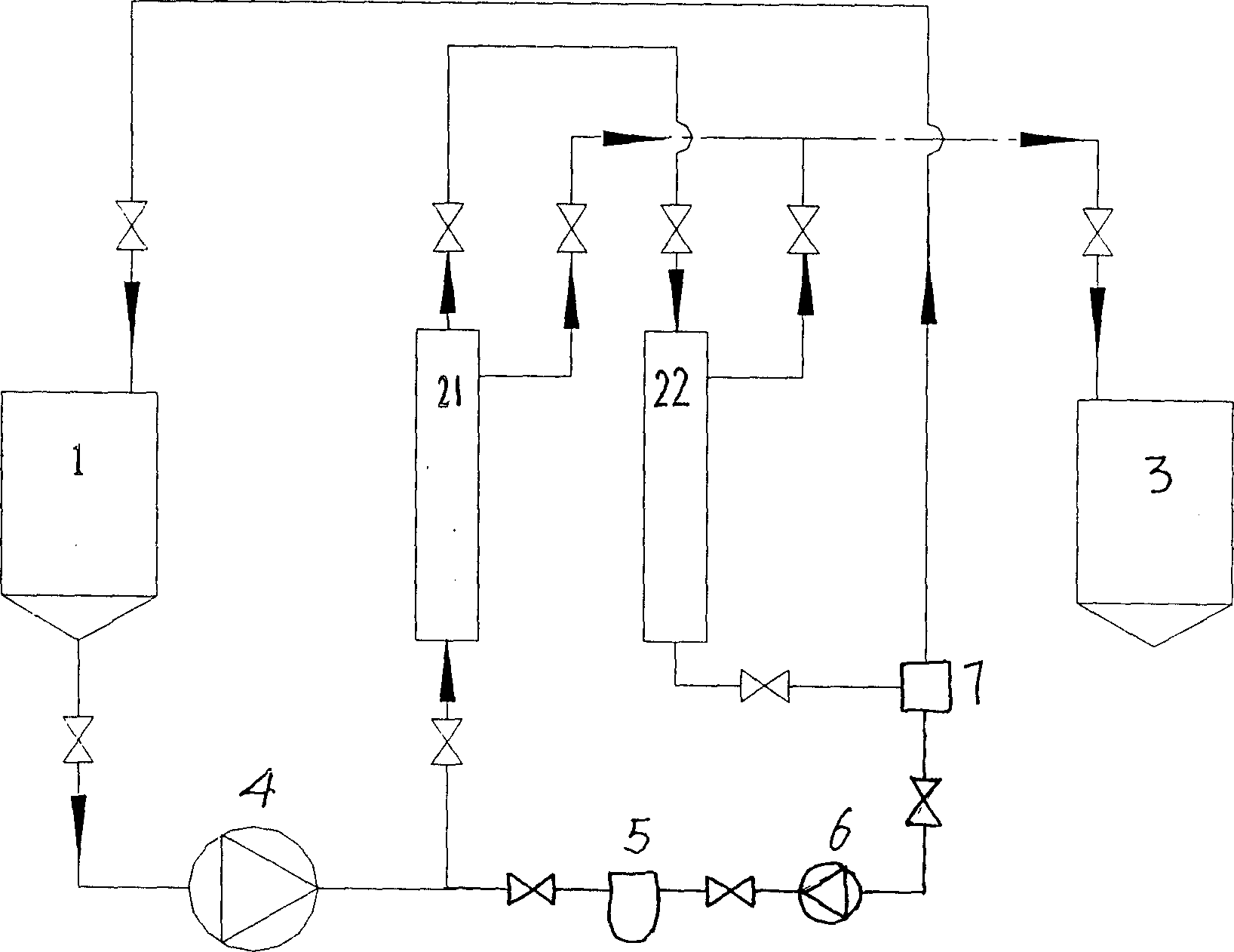

[0031] Another membrane filtration device of the present invention, see image 3 , including a stock solution tank 1 , a first membrane module 21 , a second membrane module 22 , a clean solution tank 3 and a stock solution pump 4 . The outlets of the first membrane assembly 21 and the second membrane assembly 22 are all connected with the clean liquid tank 3, and the other outlet of the first membrane assembly 21 is connected with the inlet of the second membrane assembly 22, at the inlet of the first membrane assembly 21 Be connected with adding ball groove 5; Be connected with ball liquid separator 7 at the outlet of the second membrane module 22, the outlet of the second membrane module 22 passes through ball liquid separator 7, losing ball pump 6 and adding ball groove 5 and the first The inlet of the membrane module 21 is connected.

[0032] During work, at first load an appropriate amount of regenerated balls into ball groove 5, the regenerated balls can be rubber balls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com