Container for fuel cell,fuel cell and electronic apparatus

A fuel cell and container technology, applied in the direction of fuel cells, fuel cell groups, fuel cell components, etc., can solve problems such as hindering electrochemical reactions and degrading power generation efficiency, achieve high reliability and safety, and improve mechanical reliability excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

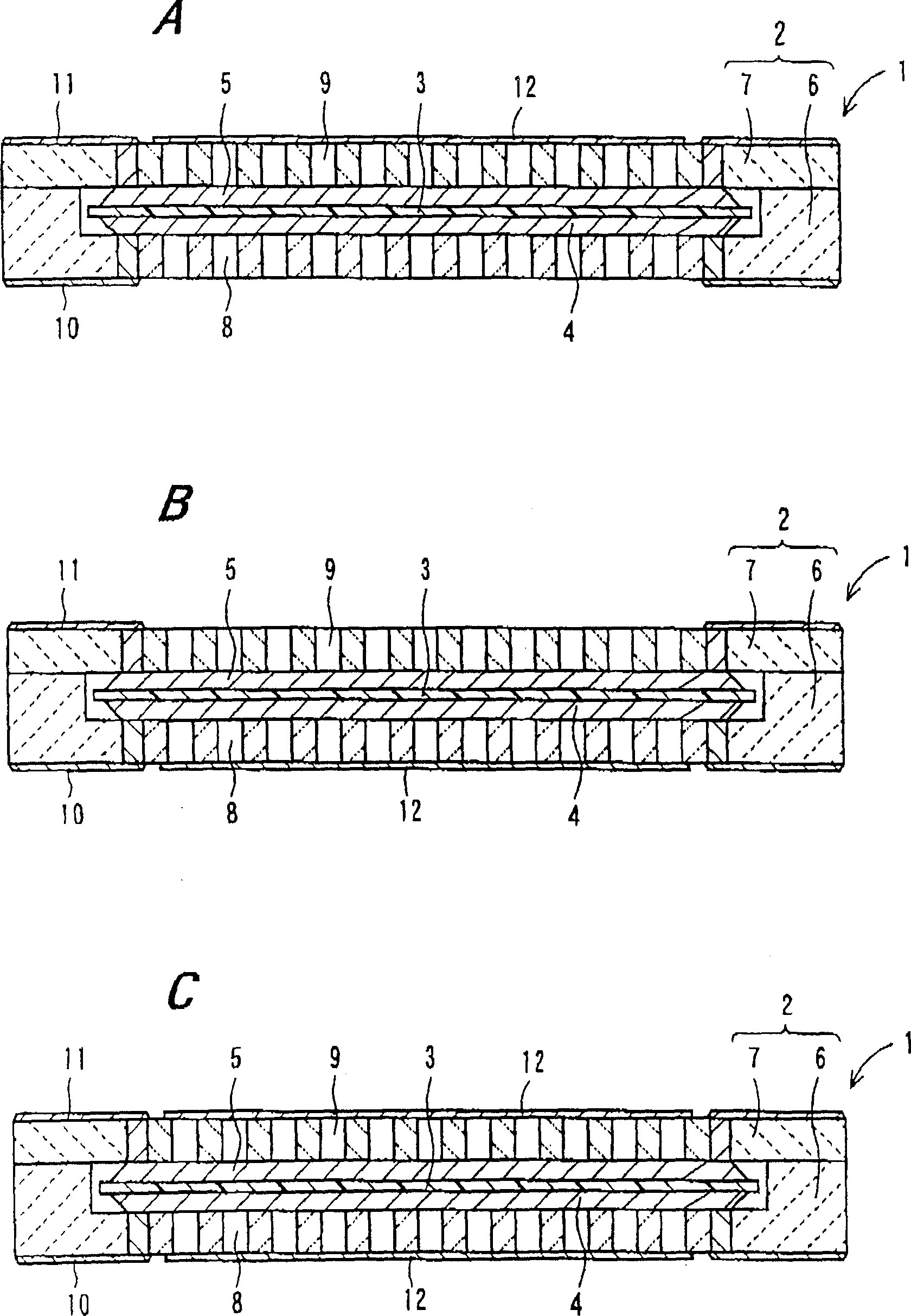

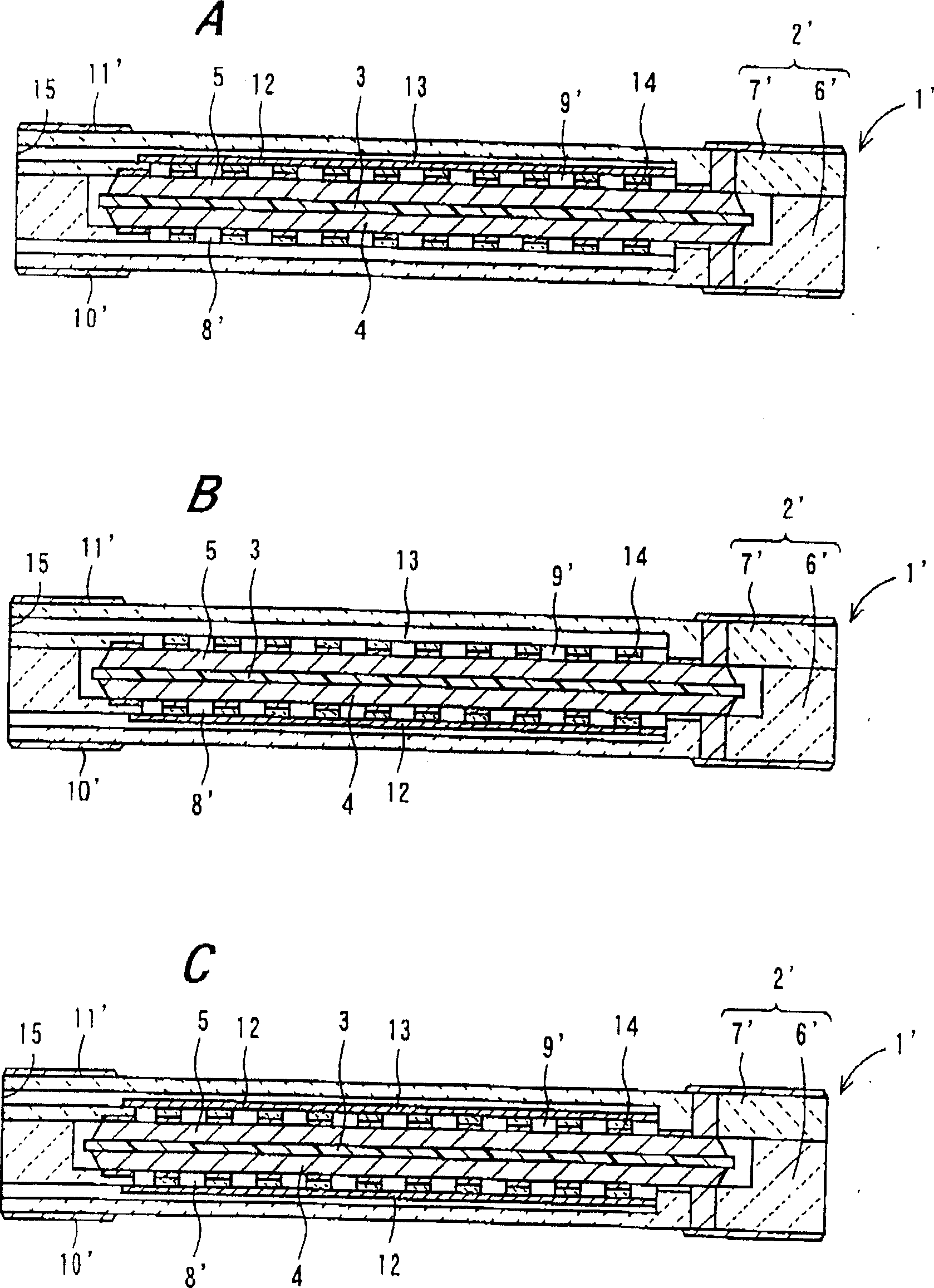

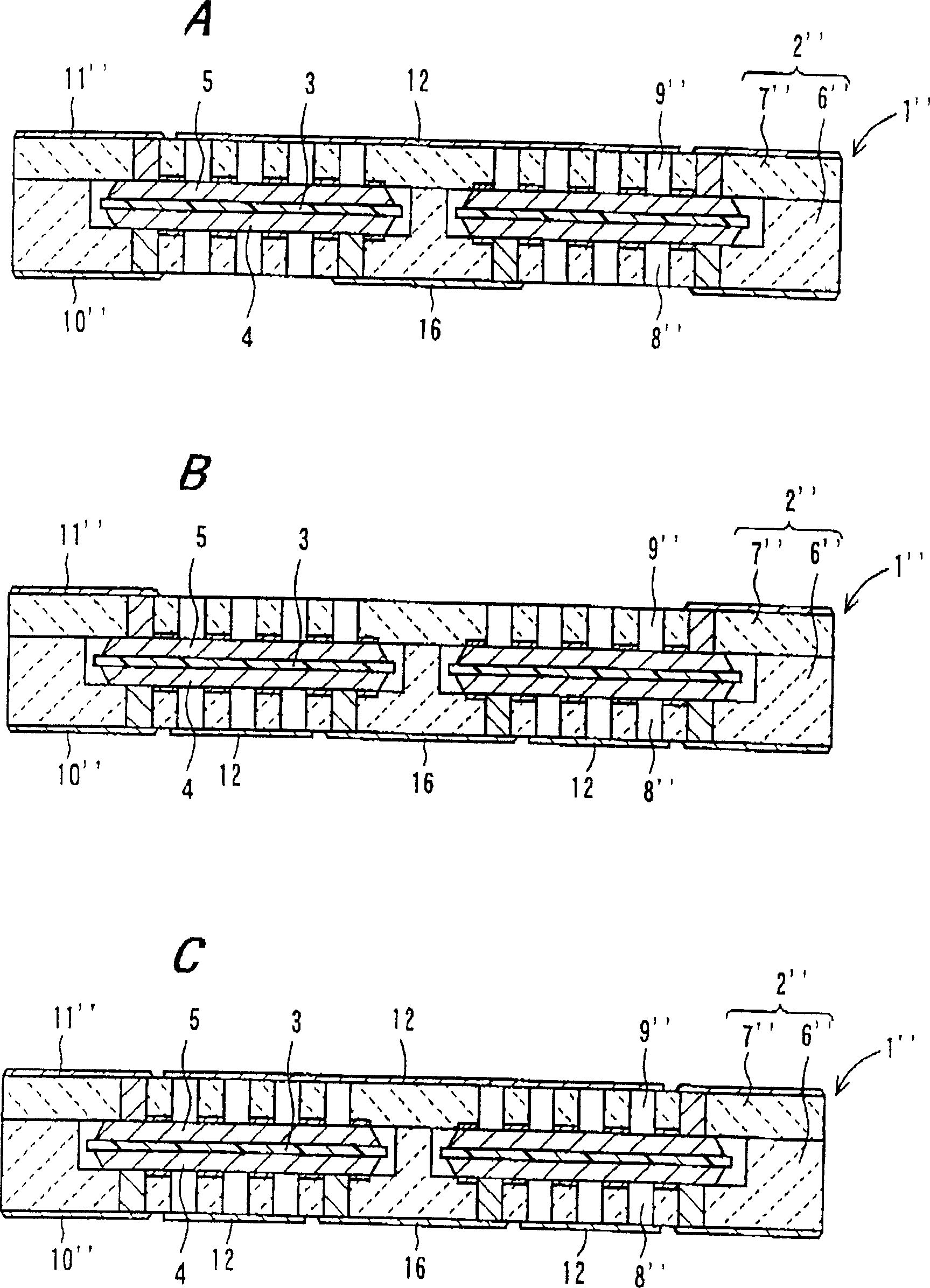

[0055] figure 1 A~ figure 1 C is a cross-sectional view showing a fuel cell container and a fuel cell using the same according to an embodiment of the present invention. exist figure 1 A~ figure 1 In C, 1 is a fuel cell, 2 is a container for a fuel cell, 3 is an electrolyte member, 4 is a first electrode, 5 is a second electrode, 6 is a substrate, 7 is a cover, 8 is a first fluid flow path, 9 Reference numeral 10 denotes a second fluid flow path, 10 denotes a first wiring conductor, 11 denotes a second wiring conductor, and 12 denotes a porous body.

[0056] In the electrolyte member 3 of the present invention, for example, a fuel electrode (not shown) serving as an anode-side electrode and an air electrode (not shown) serving as a cathode-side electrode are integrally formed on both main surfaces of an ion-conducting membrane (exchange membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com