Method for preparing steel slag water washing sand used as a substitute for yellow sand

A technology for washing sand and steel slag, applied in chemical instruments and methods, wet separation, solid waste removal, etc., can solve the problem of steel slag pellets without performance indicators and other problems, and achieve improved performance, stable performance, and significant environmental benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

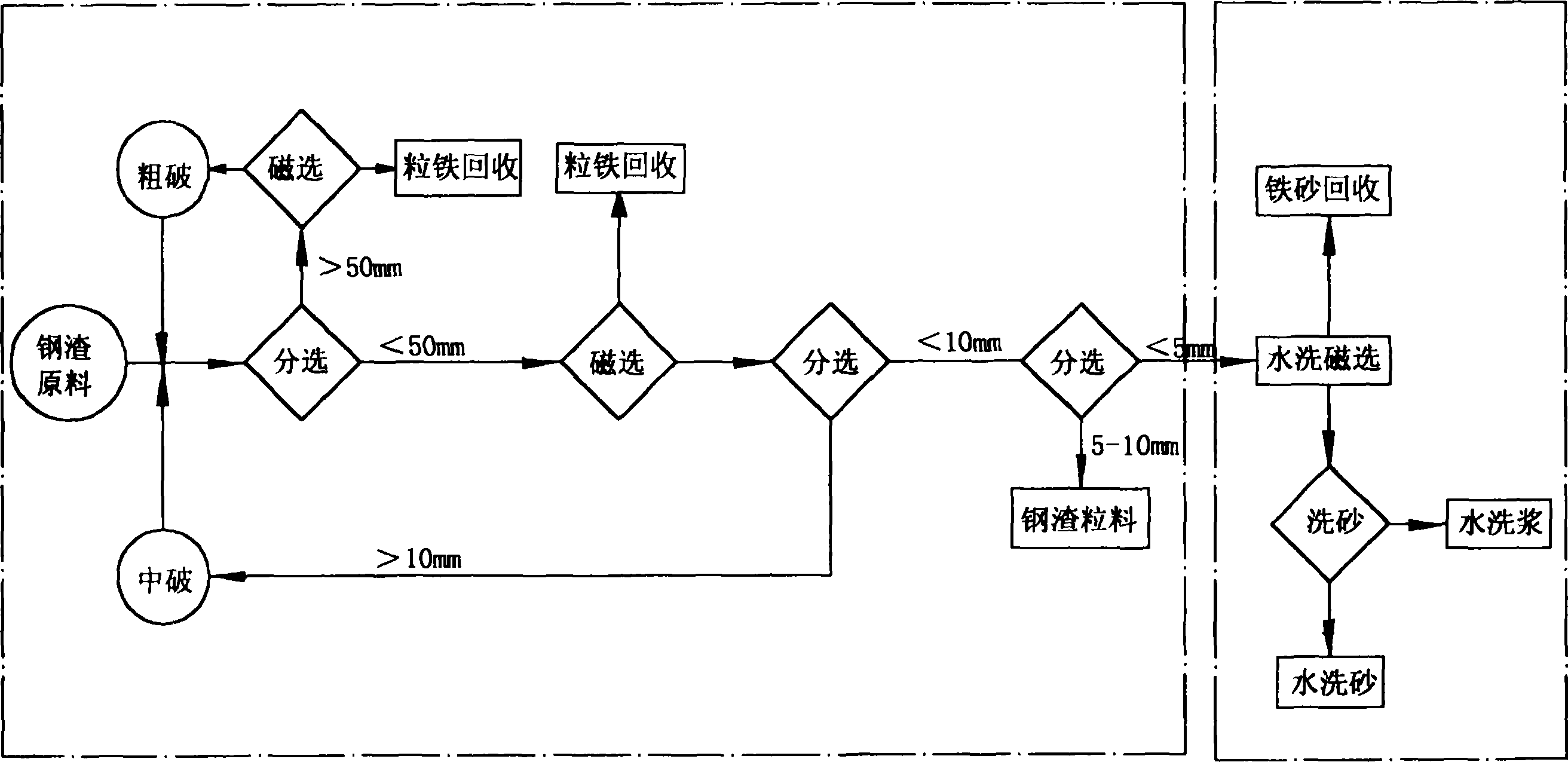

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] The invention discloses a method for preparing steel slag water-washed sand used to replace yellow sand, which comprises repeated magnetic separation, crushing, and sorting of steel slag until the particle size is less than 5mm, and then sorting, water-washing, and magnetic separation.

[0018] The specific operation steps are:

[0019] (1) Fully crushing, sorting, and magnetically separating steel slag raw materials, and concentrating steel slag magnetic separation materials and sorting materials with a particle size of <5mm;

[0020] (2) Evenly distribute the magnetic separation material and sorting material with a particle size of <5mm obtained after the previous process into the water washing magnetic separator, and fully carry out water washing and magnetic separation. While recovering the magnetic separation iron sand, Filter out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com