A kind of eps flame-retardant fire-proof board and its production process

A fireproof board and particle technology, applied in the fields of heat preservation, high flame retardant fire prevention, heat insulation, and environmental protection, can solve the problems of low production capacity, magnesium chloride anti-halogenation, long curing time period, etc., to reduce production costs, no pollution emissions, eliminate The effect of white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

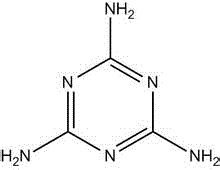

[0024] Raw material ratio: 30 parts of EPS particles, 76 parts of melamine resin, 42 parts of aluminum hydroxide, 4.5 parts of borax.

[0025] Preparation:

[0026] 1. Mixing: Weigh the melamine resin according to the formula amount, add the formula amount of aluminum hydroxide under stirring, stir evenly, then add the formula amount of curing agent borax in turn for later use. Add the formula amount of EPS particles into the mixer, and spray the prepared flame-retardant resin solution in the form of a spray under stirring at a stirring speed of 100 rpm within three minutes, and then continue to stir for two Minutes, stir evenly and discharge.

[0027] 2. Forming: put the evenly stirred material into the forming mold box and scrape it flat, and then send it into the pressure forming machine platform and use the upper and lower oil cylinders for double ejection. The compression ratio is 1:2 in the form of counter pressure, and the compression stroke is 20 seconds / time. , and ...

Embodiment 2

[0031] Raw material ratio: 35 parts of EPS particles, 85 parts of melamine resin, 48 parts of aluminum hydroxide, 5 parts of borax.

[0032] The preparation method is the same as in Example 1.

Embodiment 3

[0034] Raw material ratio: 32 parts of EPS particles, 80 parts of melamine resin, 45 parts of aluminum hydroxide, 4.8 parts of borax.

[0035] The preparation method is the same as in Example 1.

[0036] The present invention adopts a cold-pressing large mold forming process, which is a forming process of cutting a block-shaped cube with a length of 3m, a width of 1.2m, and a height of 1m and a compression ratio of 1:2 as required. There is no need to install steam boilers, no pollution emissions, energy saving and environmental protection.

[0037] The invention is the first in China, and it is a revolutionary change in the domestic thermal insulation manufacturing industry. It replaces the traditional thermoplastic molding process, and at the same time, it also replaces the thermosetting molding process imported from abroad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation vapor pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com