Bar production line cooling bed sampling robot system and sampling method

A robotic system and production line technology, applied in sampling devices, instruments, manipulators, etc., can solve the problems of low sampling efficiency, slow response speed, poor sampling accuracy, etc., and achieve the effect of high cutting accuracy, avoiding influence and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

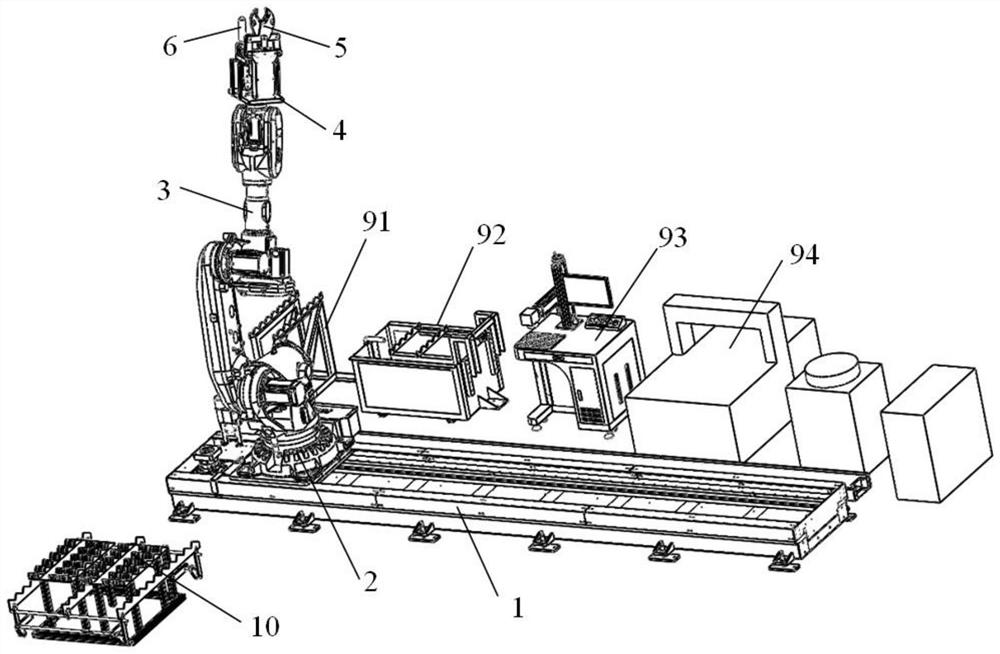

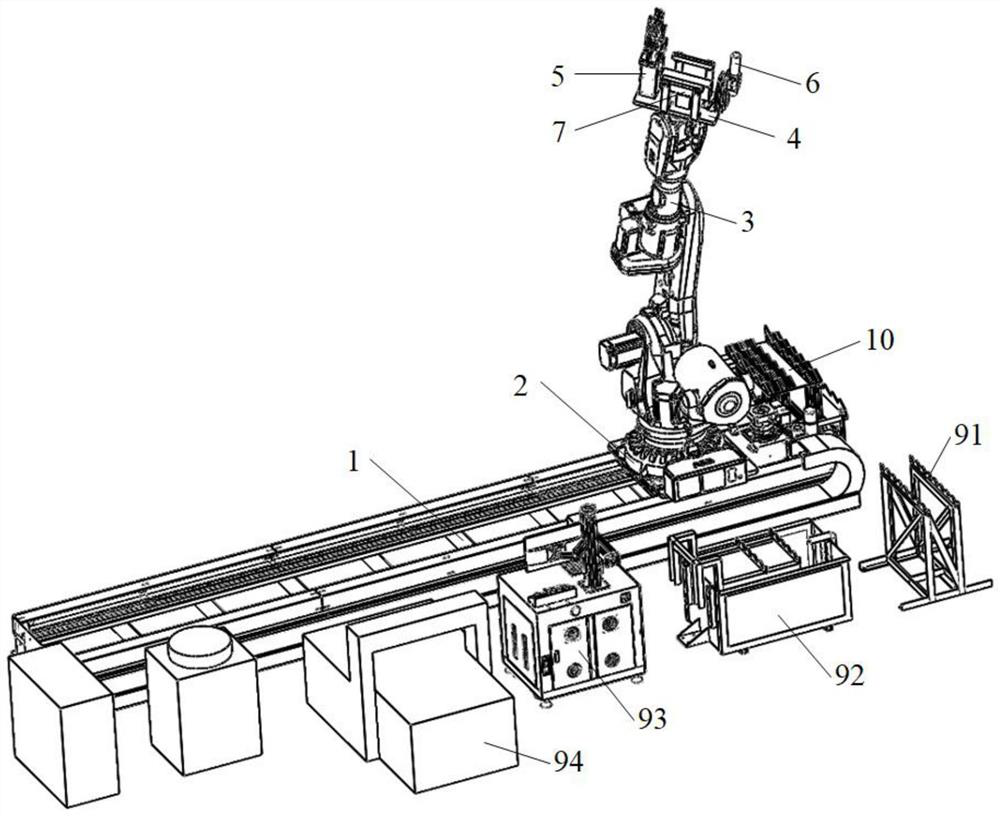

[0028] Figure 1 to Figure 4 A robotic system for cold bed sampling in a bar production line according to an embodiment of the present invention is schematically shown.

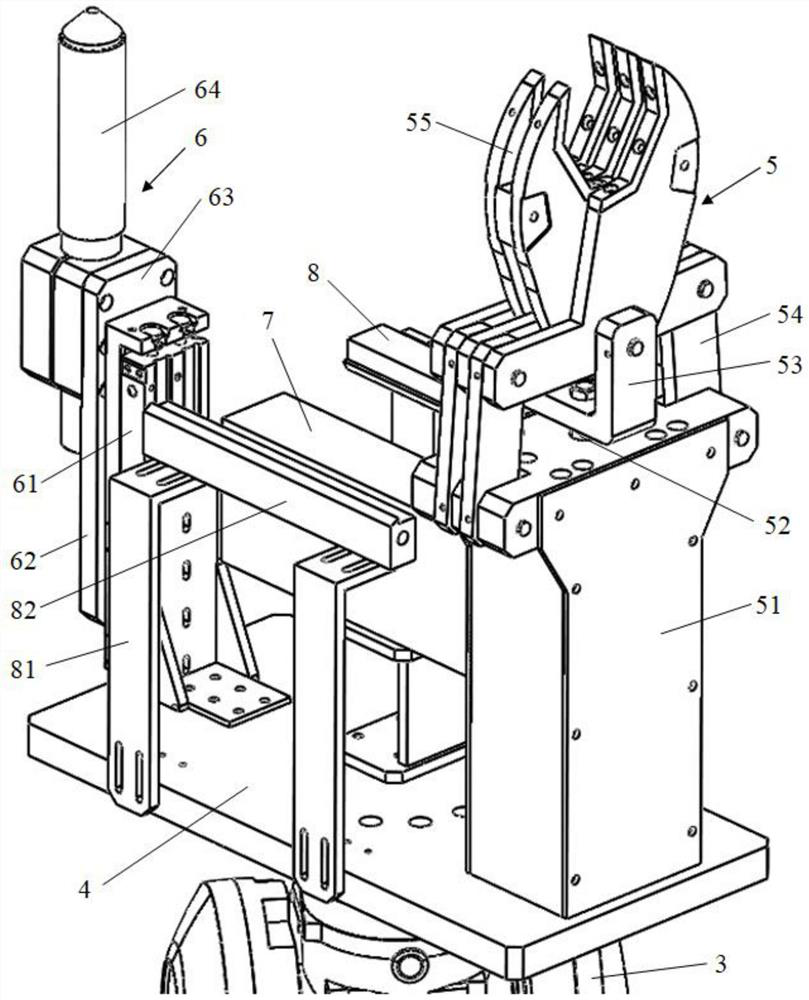

[0029] refer to Figure 1 to Figure 4 , The bar production line cooling bed sampling robot system includes a ground rail push device 1, a walking base 2, a manipulator 3, a mounting seat 4, a grabbing device 5, a shearing device 6, a visual recognition system, an air knife device 8, a sample collection system, Cooling bed sampling rack 10 and PLC control device. The walking base 2 is installed on the ground rail pushing device 1 and is pushed by the ground rail device 1 to be able to move back and forth along the ground rail device 1 . The ground rail pushing device 1 may include a track and a pushing device, the walking base 2 is matched with the track and connected with the pushing device, and the pushing device pushes the walking base 2 to move back and forth along the track. One end of the manipulator ...

Embodiment 2

[0037] The bar production line cooling bed sampling method for the bar production line cooling bed sampling robot system of Embodiment 1, comprising the following steps:

[0038] S1. The second visual device of the visual recognition system recognizes the end information of the bar and determines the appropriate sampling position; the PLC control device is set according to the sampling signal or the sampling time. After the bar is in place, the visual recognition system includes the main control device. The received position signal determines the appropriate sampling position and generates a control signal and transmits it to the PLC control device;

[0039] S2, the manipulator 3 drives the grabbing device 5, the shearing device 6 and the first visual device 7 to move to the sampling position; the PLC control device controls the walking base 2 to push the manipulator 3 to move automatically after receiving the control signal sent by the visual recognition system to a suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com