Novel composite material, and preparation method and application thereof

A composite material and a production method technology, which are applied in the fields of new composite materials and production and application, can solve the problems of waste of resources, harmful chemical odors to the human body, and unqualified materials cannot be reused, and achieve the effect of saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

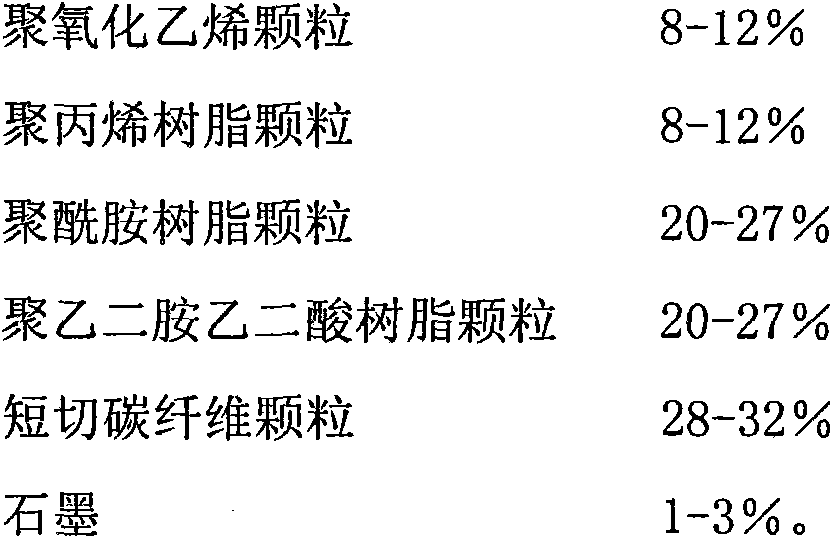

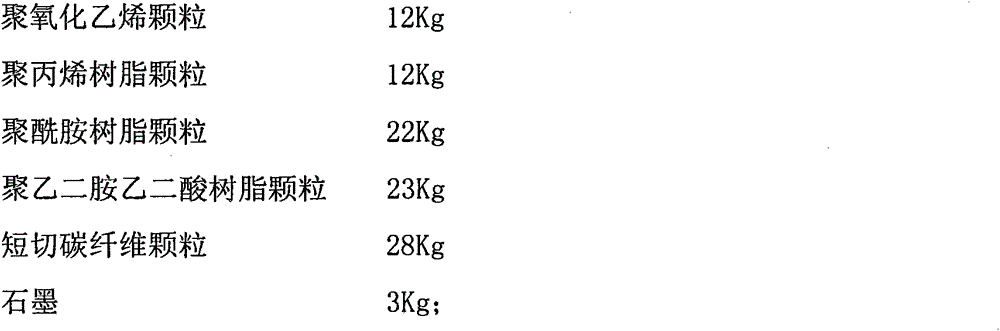

[0022] One, a novel composite material, it is based on the sum of the following component consumption and 100Kg weight ratio, wherein:

[0023]

[0024] The particle size of the above-mentioned polyethylene oxide particles, polypropylene resin particles, polyamide resin particles, polyethylenediamine oxalic acid resin particles, and chopped carbon fiber particles is less than or equal to 3×5mm;

[0025] Two, a new type of composite material production method:

[0026] (1) First, mix and stir the above-mentioned 12Kg of polyethylene oxide particles and 12Kg of polypropylene resin particles evenly, put them into an extruder at 200°C to granulate 24Kg, the particle size is less than or equal to 3×5mm, and set aside.

[0027] (2) Mix and stir the particles prepared in step (1) with 22Kg of the above-mentioned polyamide resin particles, 23Kg of polyethylenediamine oxalic acid resin particles, 28Kg of chopped carbon fiber particles, and 3Kg of graphite to make them uniform and se...

Embodiment 2

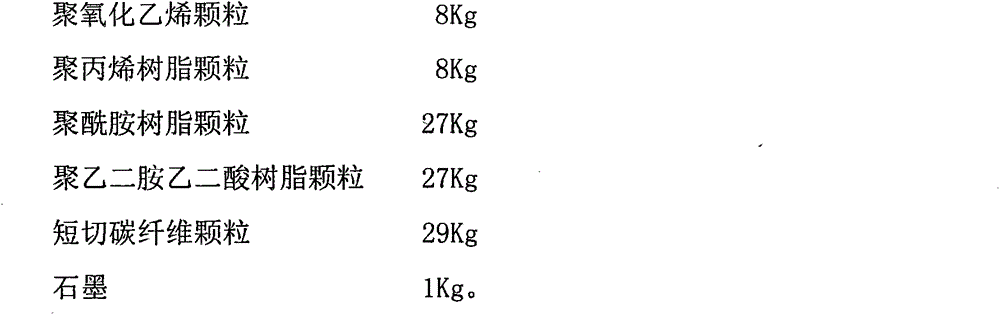

[0031] One, a novel composite material, it is based on the sum of the following component consumption and 100Kg weight ratio, wherein:

[0032]

[0033] The above-mentioned polyethylene oxide particles, polypropylene resin particles, polyamide resin particles, polyethylenediamine oxalic acid resin particles, and chopped carbon fiber particles have a particle size less than or equal to 3×5mm.

[0034] Two, a new type of composite material production method:

[0035] (1) First, mix and stir the above-mentioned polyethylene oxide granules 8Kg and polypropylene resin granules 8Kg evenly, put them into an extruder at 150°C to granulate 16Kg, the particle size is less than or equal to 3×5mm, and set aside.

[0036] (2) Mix and stir the particles prepared in step (1) with 27Kg of the above-mentioned polyamide resin particles, 27Kg of polyethylenediamine oxalic acid resin particles, 29Kg of chopped carbon fiber particles, and 1Kg of graphite to make them uniform and set aside.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com