Macrocyclic full loaded workable equipment for fabricating gasoline and diesel oil through cracking waste plastics

A gasoline and diesel, full-load technology, applied in the field of waste plastic cracking oil production equipment, can solve the problems of lower heat transfer efficiency, easy blockage of equipment and pipelines, easy fouling of heat transfer surfaces, etc., and achieve the effect of slowing down blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

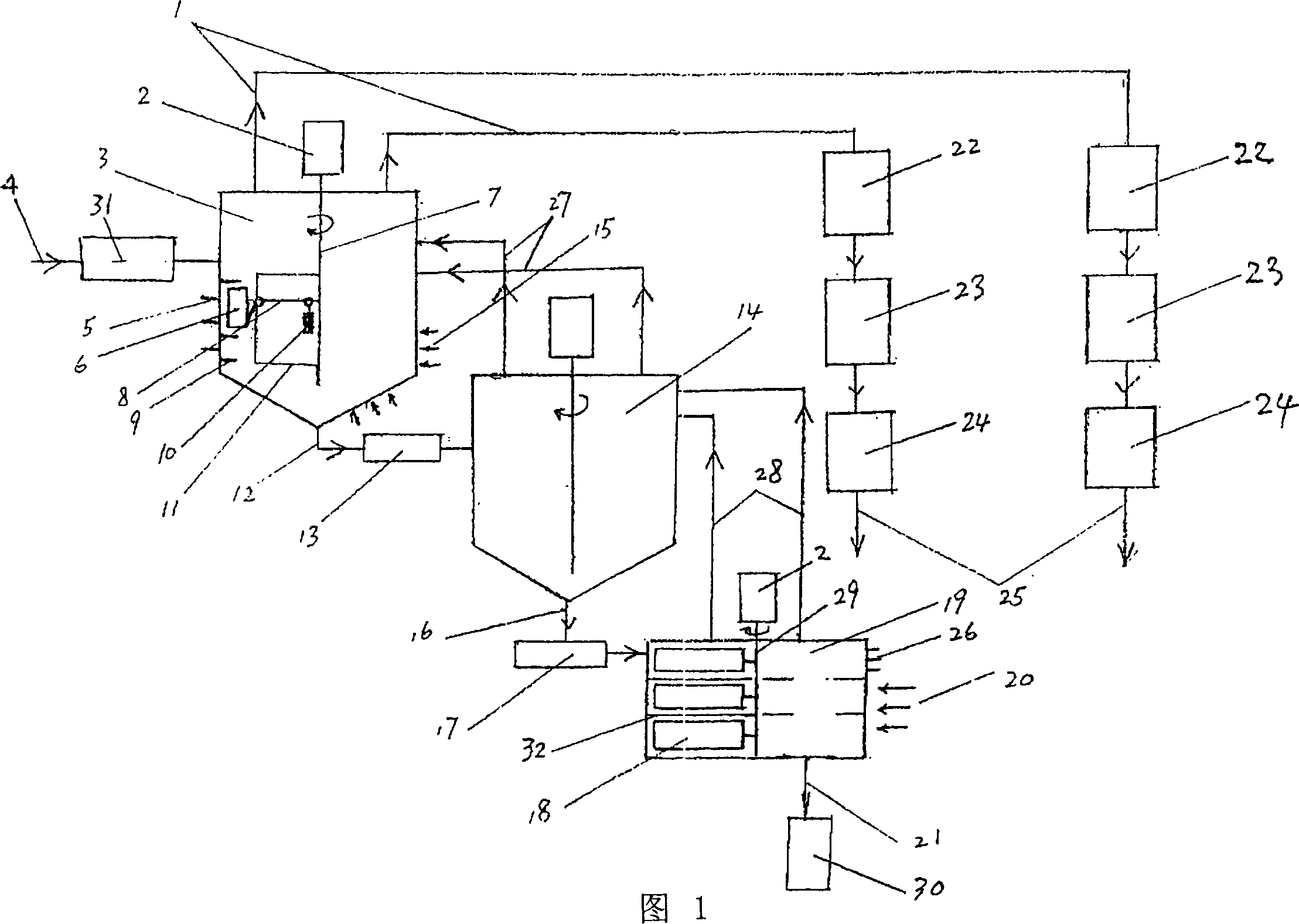

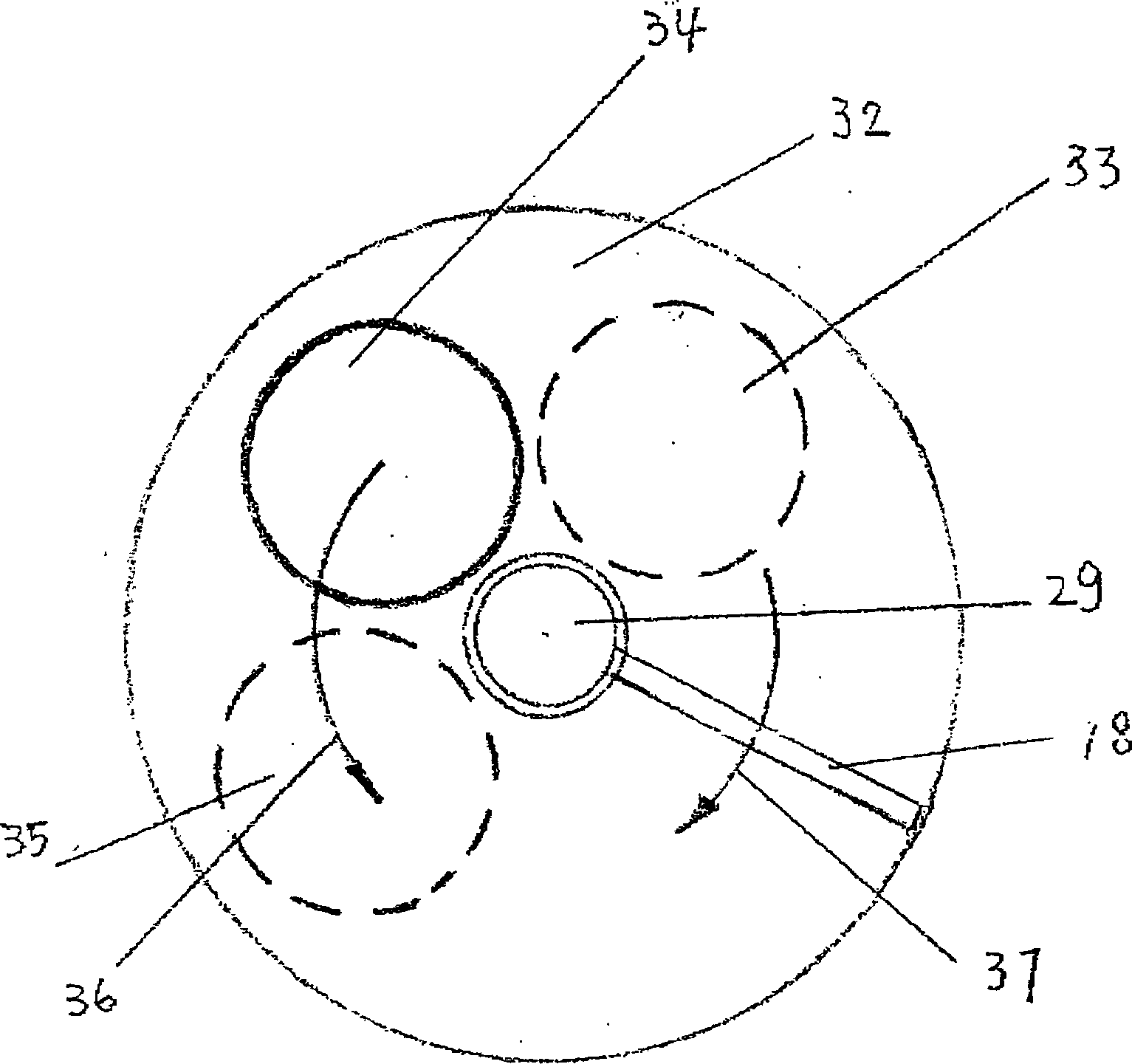

[0014] As shown in Figure 1, the waste plastic 4 containing moisture first enters the drying tank 31 to remove most of the moisture, and then enters the front thermal cracking reactor 3 in the two sets of thermal cracking reactors, and the liquid phase part of the preceding thermal cracking reactor 3 The outer wall of the reactor is heated by a heat source 15 directly or indirectly heated by a flame, and the front pyrolysis reactor 3 has outer wall fins 5 and inner wall fins 9, which can increase heat transfer intensity and improve the rigidity of the still wall. The waste plastic 4 melts into a liquid after entering the front pyrolysis reactor 3, and a small amount of pyrolysis reaction takes place. The oil and gas discharged from the pre-pyrolysis reactor 1 enters one of two or more sets of gas phase main process equipment through two or more parallel pipelines. The gas phase main process equipment can be a catalytic and condensation system, and the catalytic and condensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com