Rolling and drying combined mechanism and drying and flattening method

A technology of drying mechanism and combined mechanism, which is applied in the direction of mechanical processing/deformation, physical treatment of paper, etc., can solve the problems of low production efficiency, achieve fast heating speed, improve flatness, and ensure the effect of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

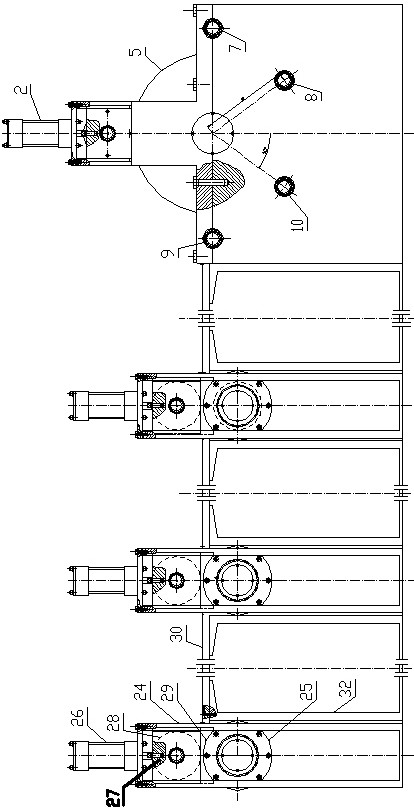

[0064] figure 1 The direction from right to left is the running direction of the anti-seepage paper 23 .

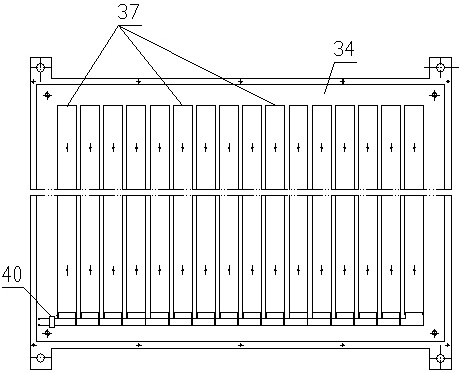

[0065] Such as Figure 1 to Figure 11 As shown, the combined rolling and drying mechanism of the present invention includes several rolling mechanisms and several electric heating drying mechanisms arranged alternately along the forward direction of the anti-seepage paper 23 to be processed; the number of rolling mechanisms and electric heating drying mechanisms is the same;

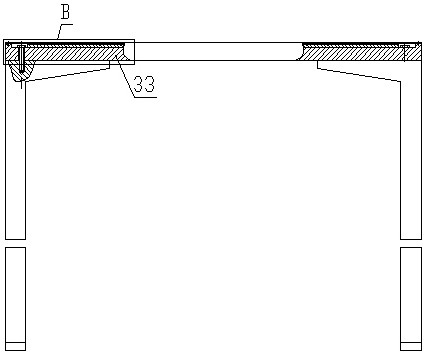

[0066] The rolling mechanism comprises a rolling frame 24, the middle part of the rolling frame 24 is equipped with a lower pressure roller 25 through a bearing, the rolling frame 24 top is fixedly connected with a rolling cylinder 26, and the extension rod of the rolling cylinder 26 extends downwards. Go out and be connected with upper roller installation frame 27, upper roller installation frame 27 is positioned at rolling machine frame 24, upper roller installation frame 27 is installed with upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com