Fuel cell

A technology of fuel cells and battery cells, applied in the direction of fuel cells, fuel cell groups, fuel cell additives, etc., can solve problems such as low rigidity, membrane degradation, poor air permeability, etc., achieve rigidity improvement, improve rigidity, and inhibit trapped diffusion The effect of layers and films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, refer to Figure 1 to Figure 6 (but Figure 6 is a comparative example) illustrates the fuel cell of the present invention.

[0030] The fuel cell of the present invention is a solid polymer electrolyte fuel cell 10 . The solid polymer electrolyte fuel cell 10 is mounted, for example, in a fuel cell vehicle. However, it can also be applied to other than automobiles.

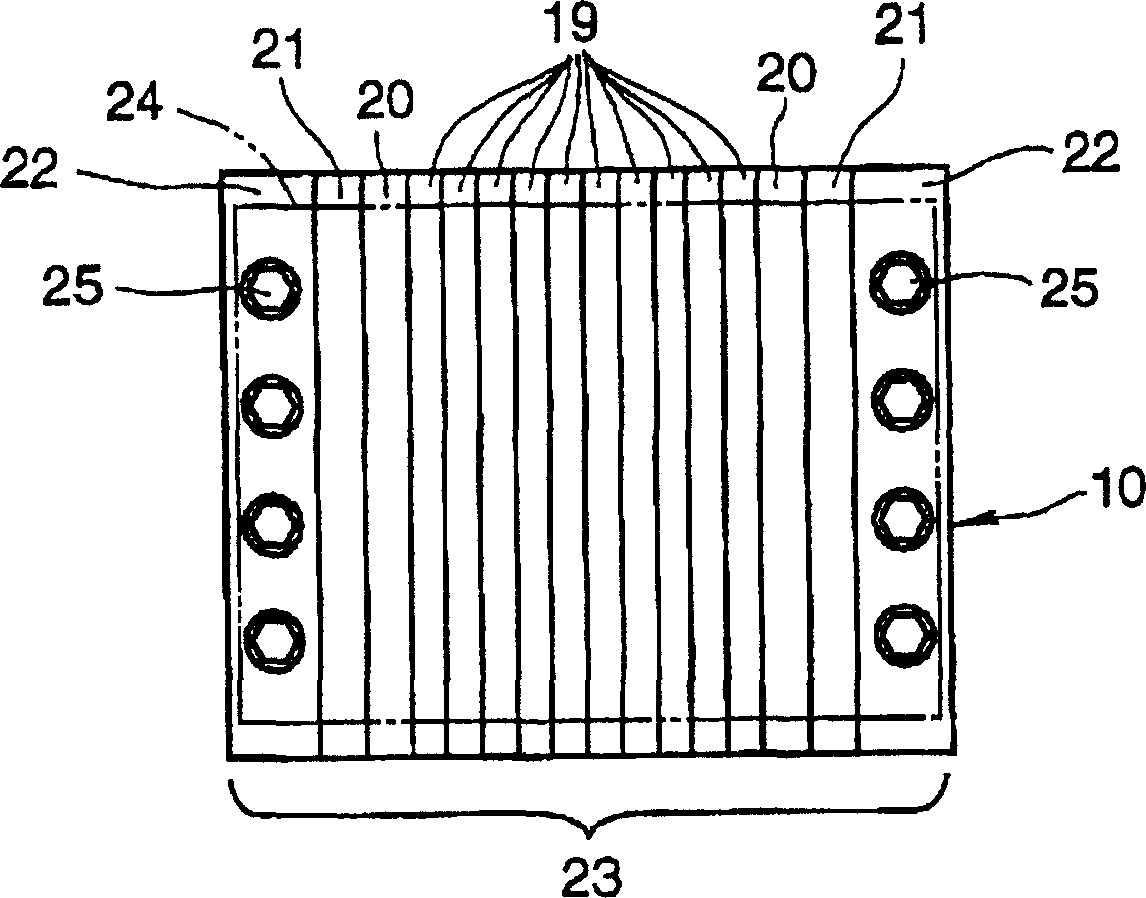

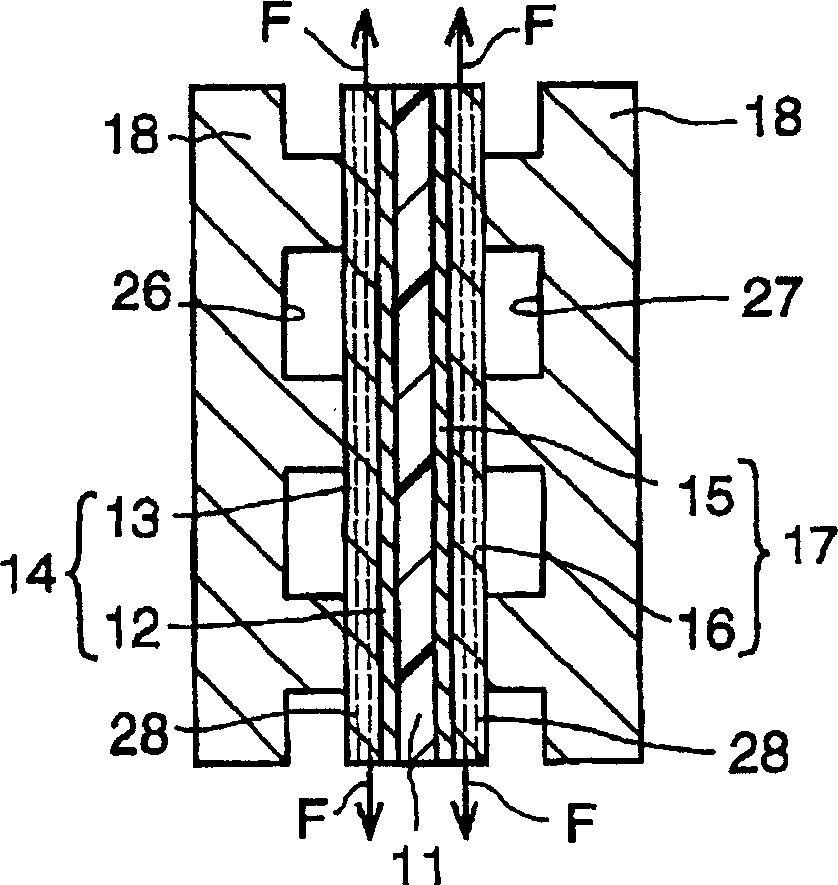

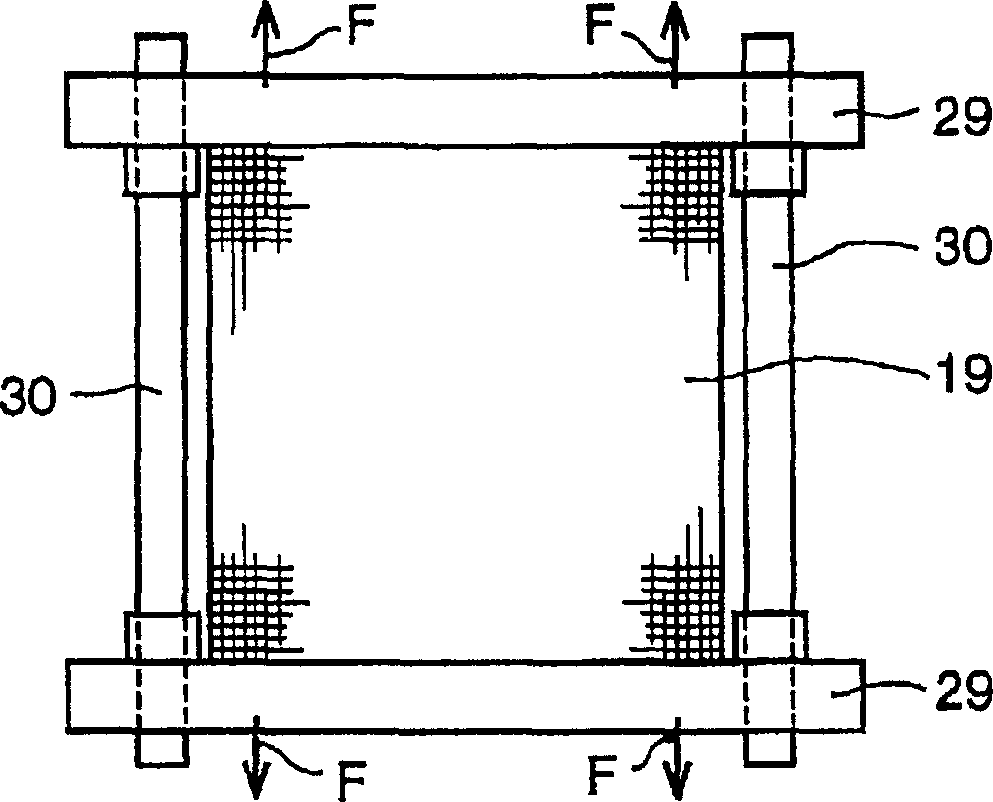

[0031] Such as figure 1 , figure 2 As shown, the solid polymer electrolyte fuel cell 10 is constituted by stacking cells 19 composed of a membrane-electrode assembly (MEA: Membrane-Electrode Assembly) and a separator 18 .

[0032] The MEA includes: an electrolyte membrane 11 composed of an ion exchange membrane, a diffusion electrode 14 (anode) composed of a catalyst layer 12 and a diffusion layer 13 disposed on one side of the electrolyte membrane 11, and a diffusion electrode 14 (anode) disposed on the other side of the electrolyte membrane 11. The catalyst layer 15 and the diffusion layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com