Improvement of thermal conductivity and luminosity promote structure of LED

A technology of light-emitting diodes and heat conduction, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of hindering the conduction and heat dissipation of light-emitting diodes, affecting the light-emitting effect or lighting effect, and failing to exert their due, so as to increase the length of the beam irradiation. , Improve the heat dissipation effect, the effect of good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

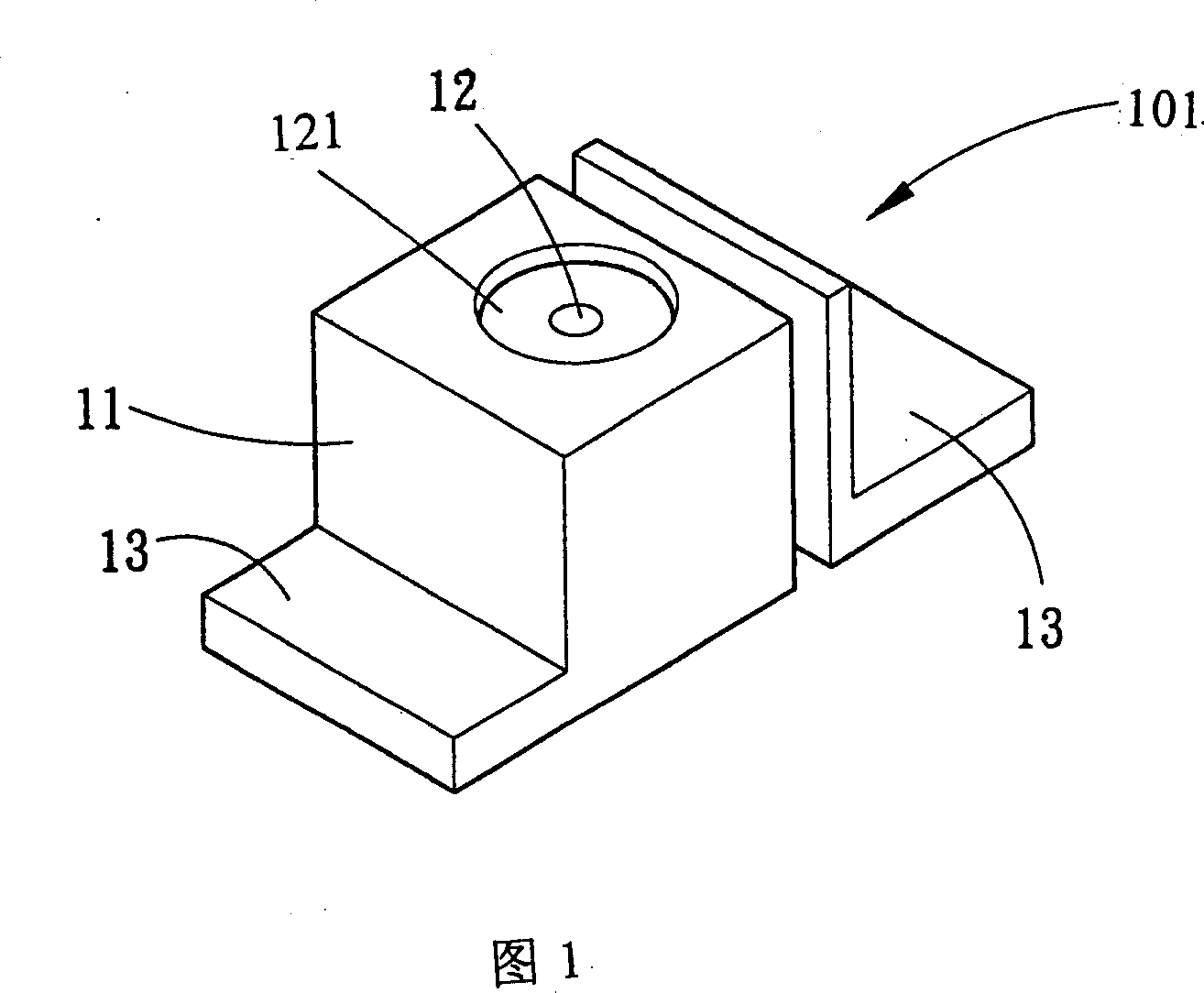

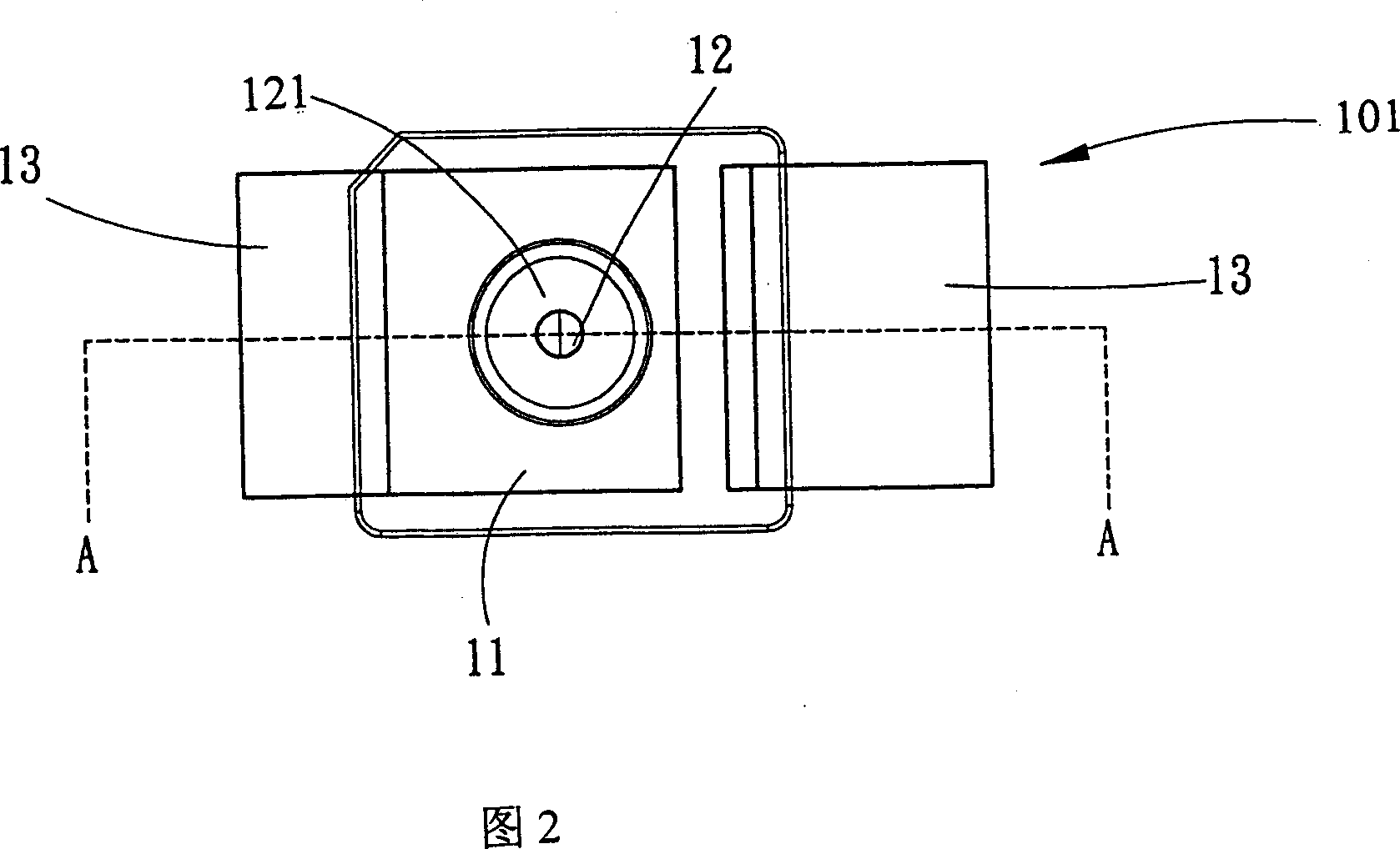

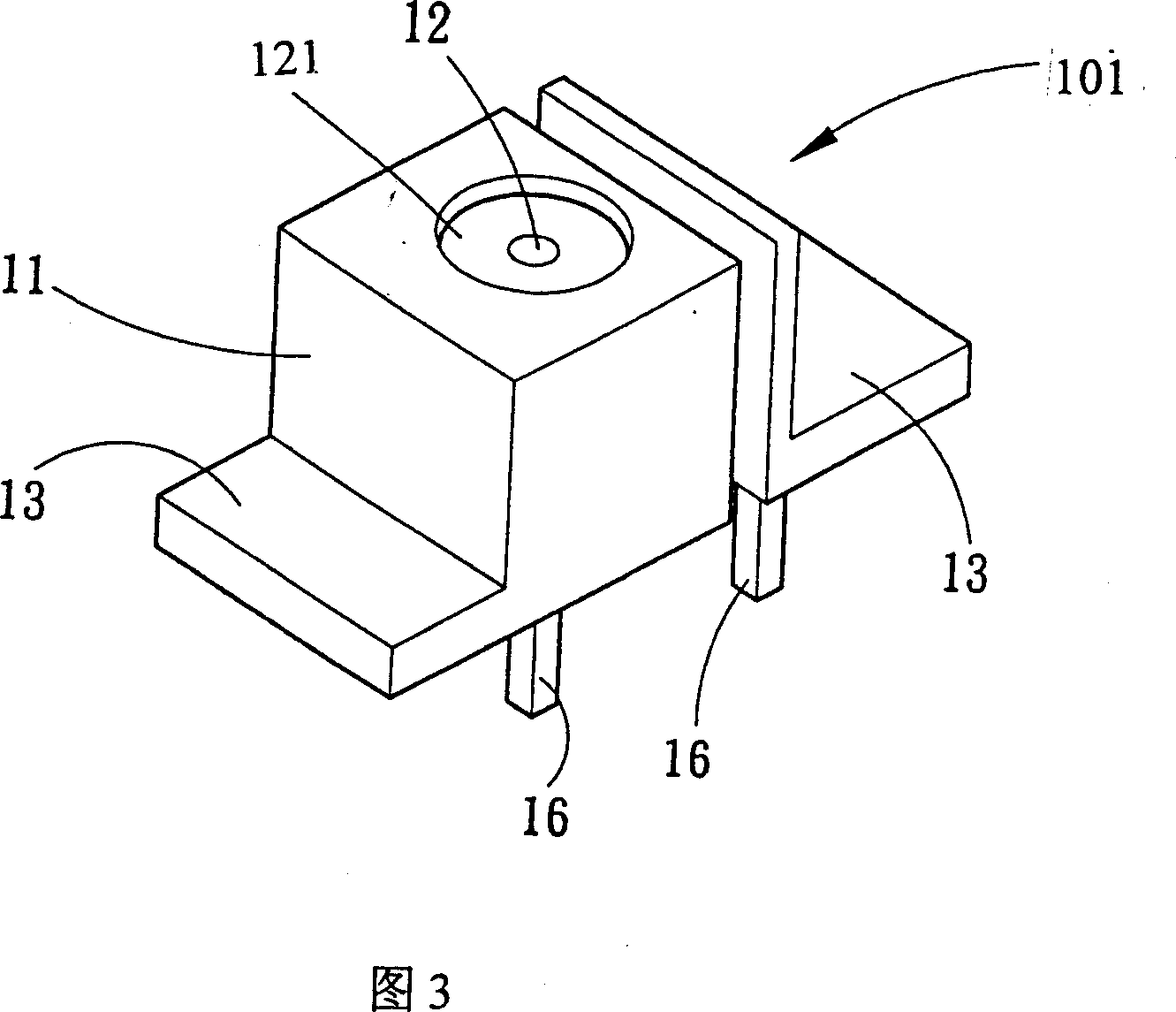

[0069] Referring to Fig. 1 to Fig. 21, it can be clearly seen that the heat conduction and luminosity structure of the light-emitting diode provided by the present invention is mainly aimed at brackets 101 (double cooling fins), 102 (four cooling fins), 103 ( No cooling fins) (or other feasible shapes) on the cathode stand 11 upper end forms a bowl cup structure 121,122,123,124, for holding light-emitting chip 150 in above-mentioned bowl cup 121,122,123,124 most The bottom is at least provided with a concave portion 12 whose diameter or area is relatively smaller than the bottom surface of the light-emitting chip (the best is between 15% and 35% of the area of the bottom surface of the chip, and the feasible implementation range is between about 5% and 95%), and the concave portion The shape of 12 can be round, square, rectangular, rhombus, etc., and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com