Heat insulating structure body

A technology of structure and thermal insulation material, applied in the direction of protecting pipelines, heat exchange equipment, lighting and heating equipment through thermal insulation, can solve problems such as thickening thermal insulation materials, and achieve lower equipment costs, lower costs, and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

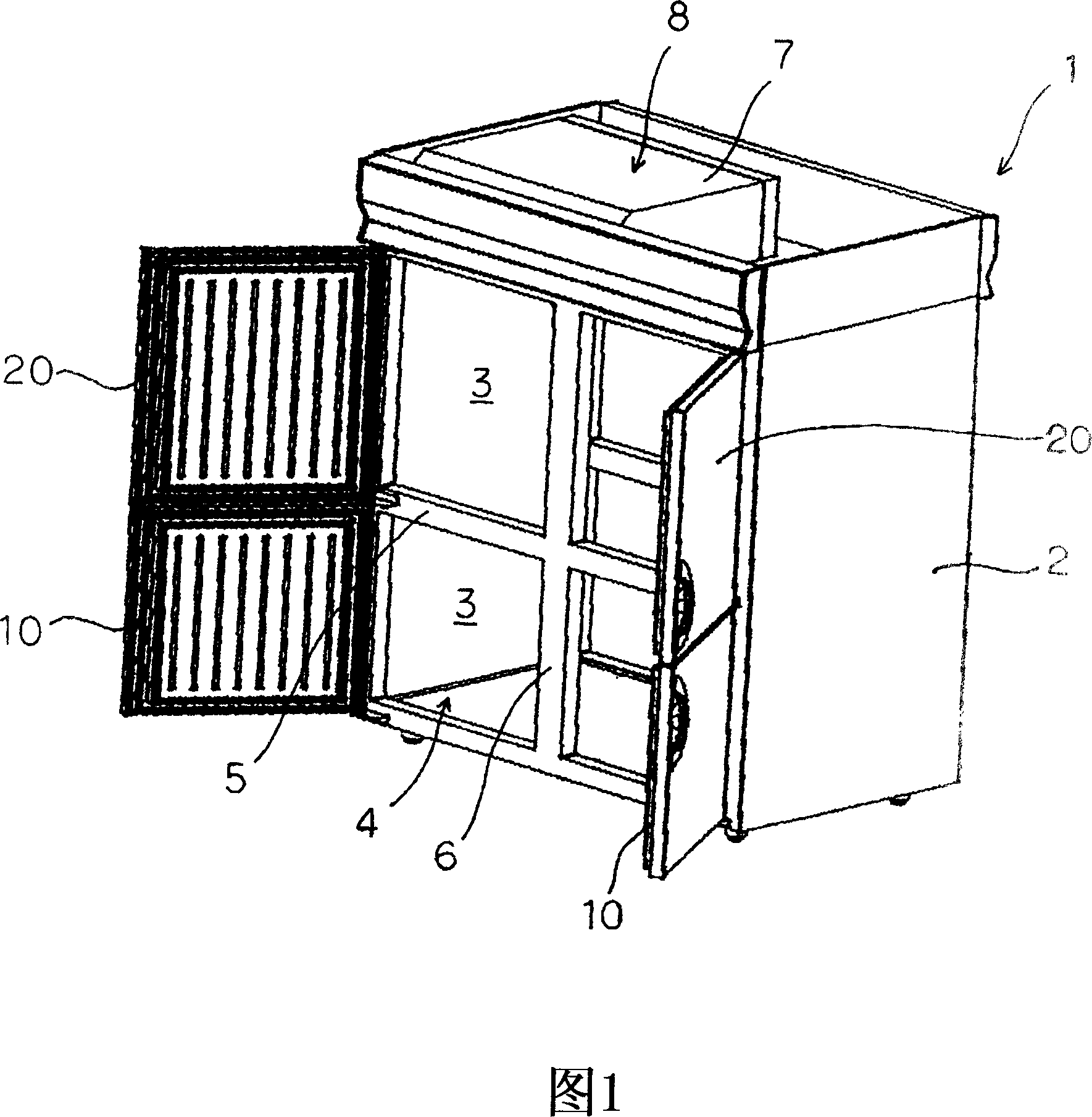

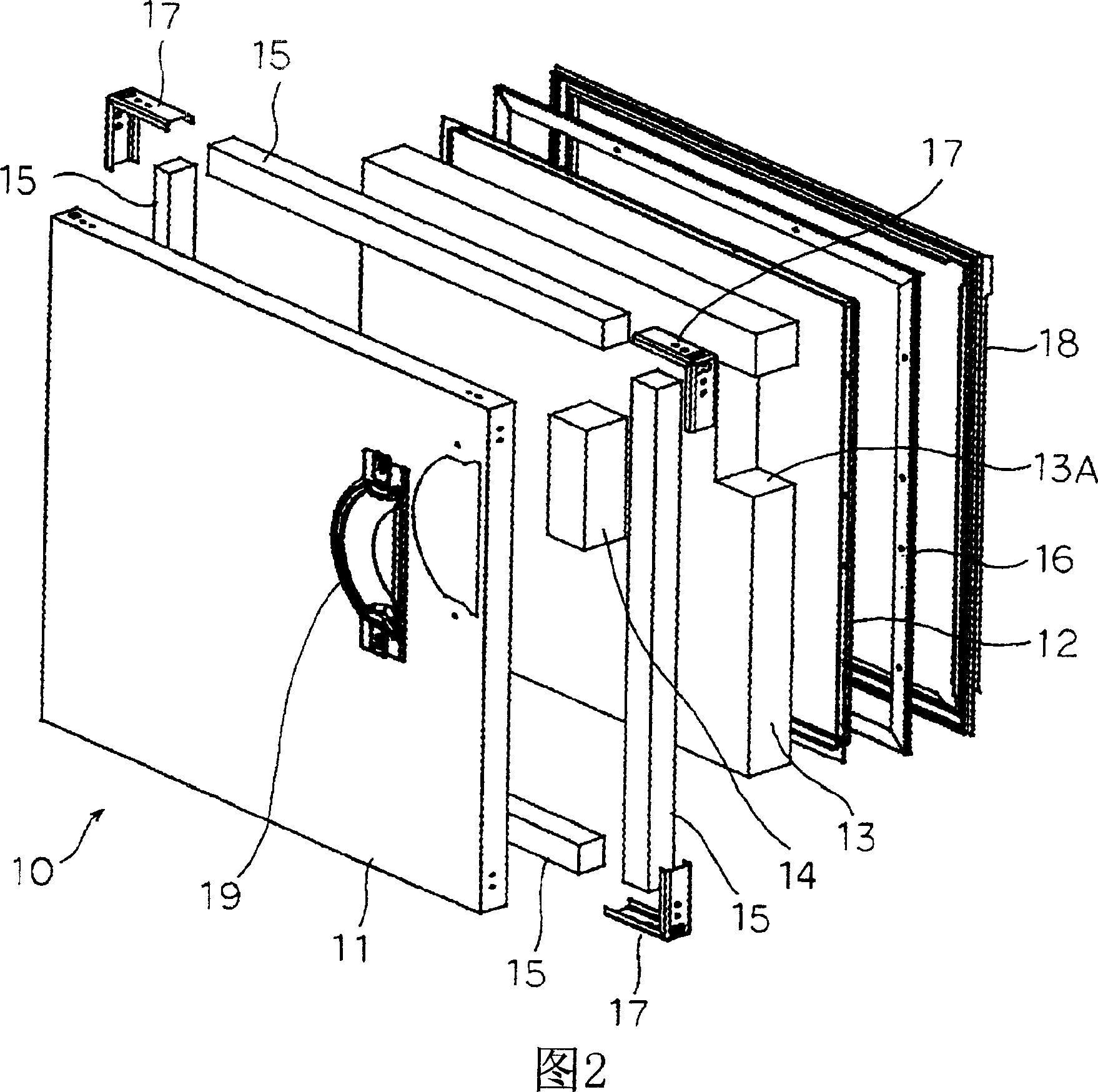

[0037] Next, embodiments of the present invention will be described in detail based on the drawings. Fig. 1 is a perspective view showing a commercial freezer 1 provided with a heat insulating structure according to the present invention, and Fig. 2 is a disassembled perspective view showing an insulating door of the commercial freezer 1 shown in Fig. 1 . The freezer 1 of the embodiment is, for example, a vertical commercial freezer installed in a kitchen of a hotel or a restaurant, and is constituted by a heat insulating box 2 opened at the front.

[0038]The front opening 4 of the storage compartment 3 constituted by the heat insulating box 2 is partitioned into up, down, left, and right at the central portion by an intermediate partition 5 extending in the horizontal direction and a vertical partition 6 extending in the vertical direction. On the left side of the vertical compartment 6, there is a storage room for storing cooked food (cooking) or food materials in the upper...

Embodiment 2

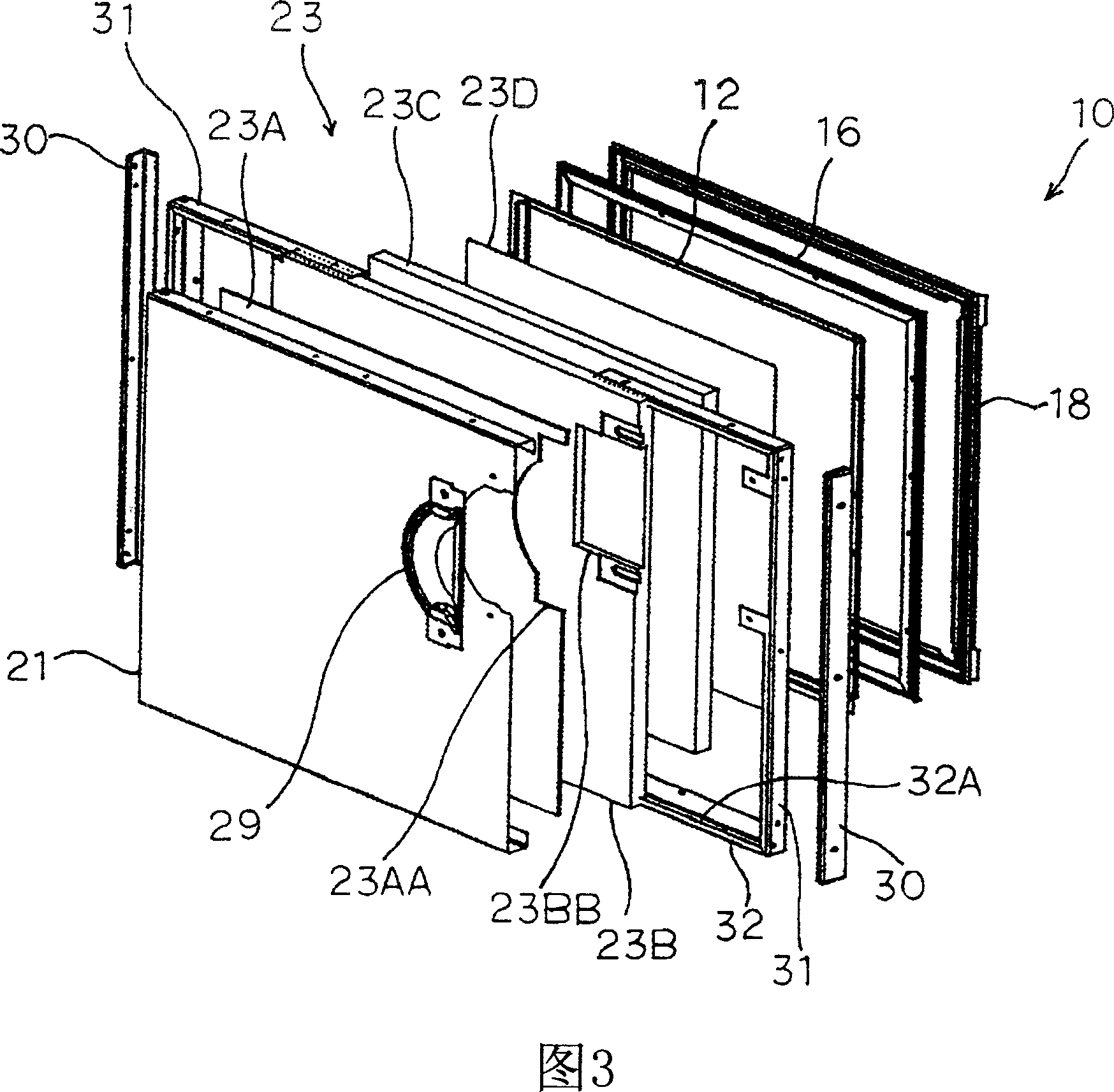

[0053] Fig. 3 is an exploded perspective view showing an insulating door 10 according to another embodiment of the present invention. In addition, the same code|symbol is attached|subjected to the same part as the above-mentioned embodiment, and the description is abbreviate|omitted. In the freezer 1 described with the above-mentioned embodiment, the insulating door 10 is composed of a face material and a heat insulating material 23, wherein the face material is an outer material 21 obtained by bending a steel plate into a U-shaped side surface, and the outer material 21 is formed by closing the outer material. 21 is constituted by a flat plate-shaped inner surface material 12 installed with an opening;

[0054] Both surface materials (the outer surface material 21 and the inner surface material 12 ) are made of the same synthetic resin or steel plate as described above. A handle 29 is provided in the vicinity of the upper part of the outer surface material 21 (on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com