Chemistry strengthened biological fluidizing recombination reactor

A biological fluidization and biological fluidized bed technology, which is applied in the field of chemically enhanced biological fluidization composite reactors, can solve the problems of unsatisfactory solid-liquid separation effect, unsatisfactory discharge of ammonia nitrogen effluent, etc. Separation effect, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

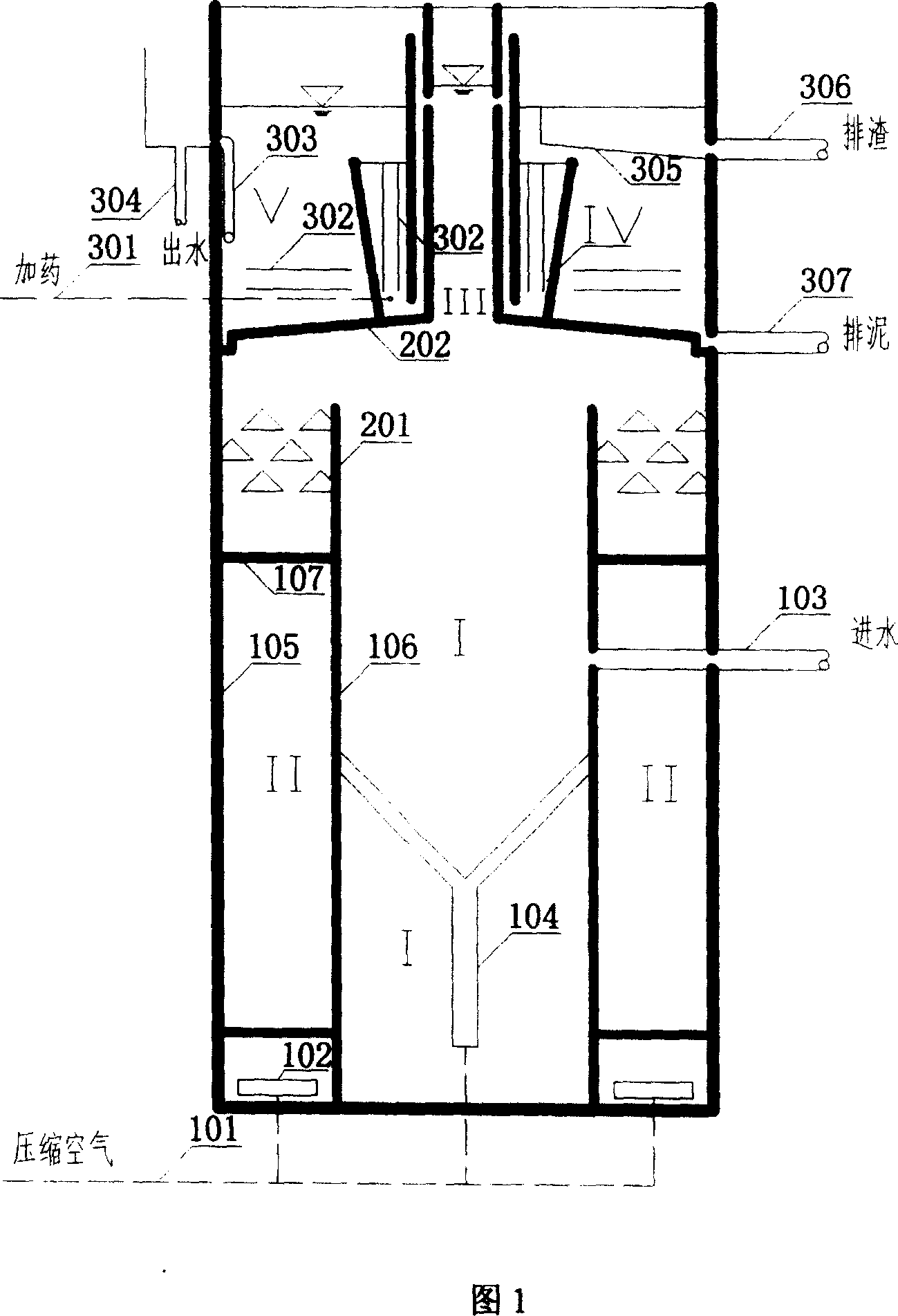

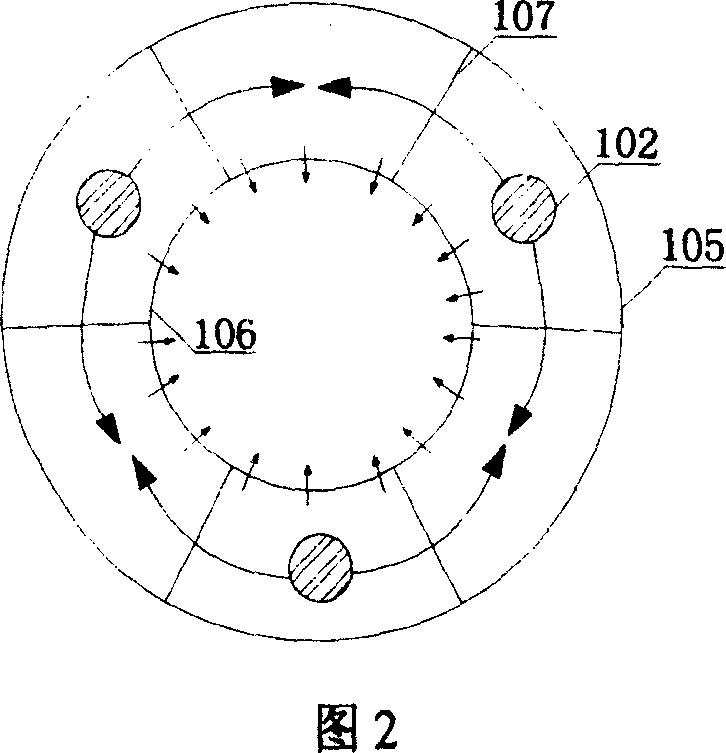

[0016] An embodiment of the chemically enhanced biological fluidized compound reactor described in the present invention is shown in FIG. 1 . The lower part of the biofluidized composite reactor is an internal circulation three-phase biological fluidized bed reaction zone, the middle is a three-phase separator to realize the three-phase separation of solid, liquid and gas, and the top is an electrolytic air flotation device to realize efficient solid-liquid separation reactor. The reaction zone of the fluidized bed is mainly composed of aerobic fluidized reaction zone II and anoxic zone I. At least one set of pole plates 302 are respectively arranged in the solid-liquid rising zone IV and the air flotation clarification zone V of the electrolytic air flotation reactor.

[0017] The chemically intensified biological fluidized composite reactor uses steel plate as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com