Method and device for rinsing fabric in roped form

A textile, rope-like technology, applied in the field of washing rope-like textiles, can solve problems such as uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

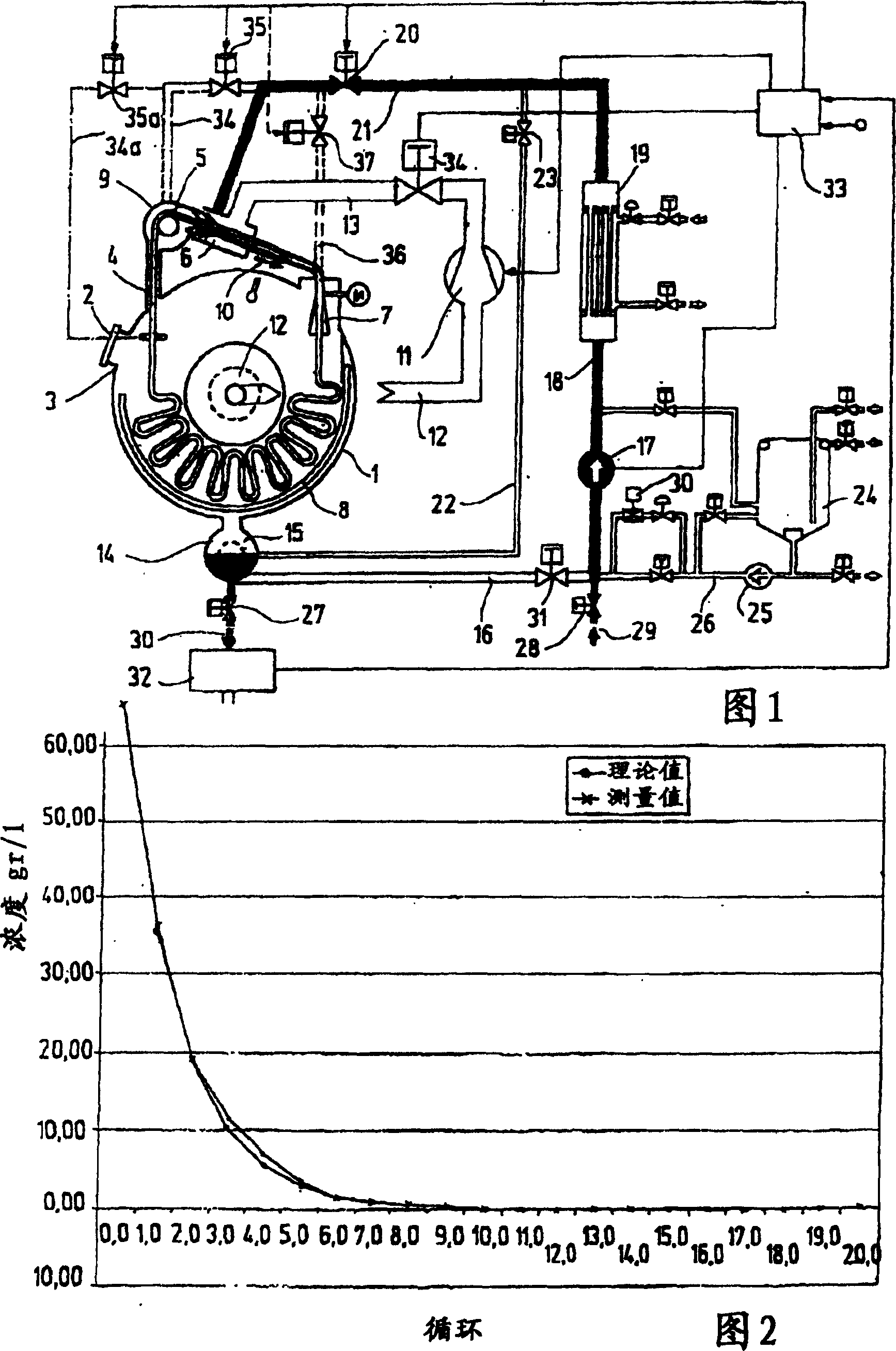

[0038] The high-temperature (HT) piece dyeing machine shown schematically in FIG. 1 has a pressure-resistant cylindrical container 1 into which an operating opening 3 closable by a cover 2 opens, through which a rope-like fabric 4 can be introduced. The rope-like fabric 4 is inserted via an externally driven winch 5 into a Venturi delivery nozzle 6 , to which a folder 7 is attached. The folder 7 stores the strand 4 discharged from the delivery nozzle 6 folded in a storage 8 from which the continuous strand 4 is withdrawn via the capstan 5 . The capstan 5 and the delivery nozzle 6 are mounted in respective housing parts 9 which are fluid-tightly connected to the container 1 . After the rope-like fabric 4 is introduced through the manipulating hole 3, it is connected at each end to form a continuous loop of fabric.

[0039] The conveying nozzle 6 is supplied with a gaseous conveying medium flow, which circulates the continuous web 4 in a circulation direction indicated by the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com