Optical recording media

A technology for optical recording and media, applied to optical record carriers, optical recording/reproducing, recording layers, etc., can solve the problems of inconvenience, management and time-consuming, and achieve the effect of convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, an optical recording medium according to a preferred embodiment of the present invention will be described with reference to related drawings.

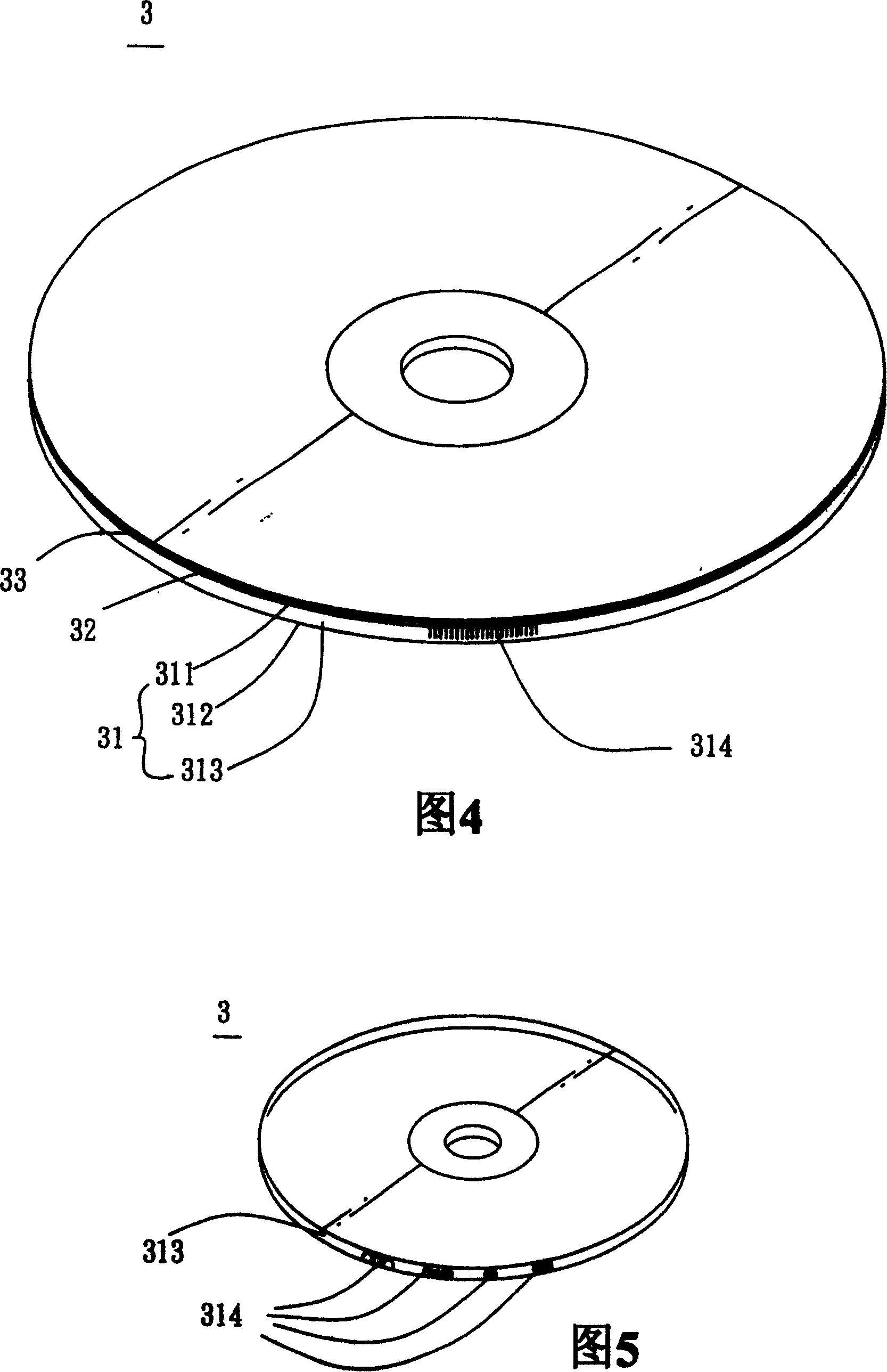

[0042] See also shown in Figure 4, according to the optical recording medium 3 of preferred embodiment of the present invention, comprise a substrate 31, a reflection layer 32 and a protection layer 33, wherein, substrate 31 has a first surface 311, a second surface 312 and a disc outer peripheral surface 313, the second surface 312 is opposite to the first surface 311, the disc outer peripheral surface 313 is between the first surface 311 and the second surface 312, and the optical disc outer peripheral surface 313 is formed with at least one The pattern 314 ; the reflective layer 32 is disposed on the first surface 311 ; the protection layer 33 is disposed on the reflective layer 32 .

[0043] Most of the substrate 31 is made of polycarbonate which is a transparent material. The substrate 31 with a first surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com