Screw anchored joint prosthesis

A hip joint prosthesis, screw technology, applied in the direction of the prosthesis, shoulder joint, ankle joint, etc., can solve problems such as overall instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

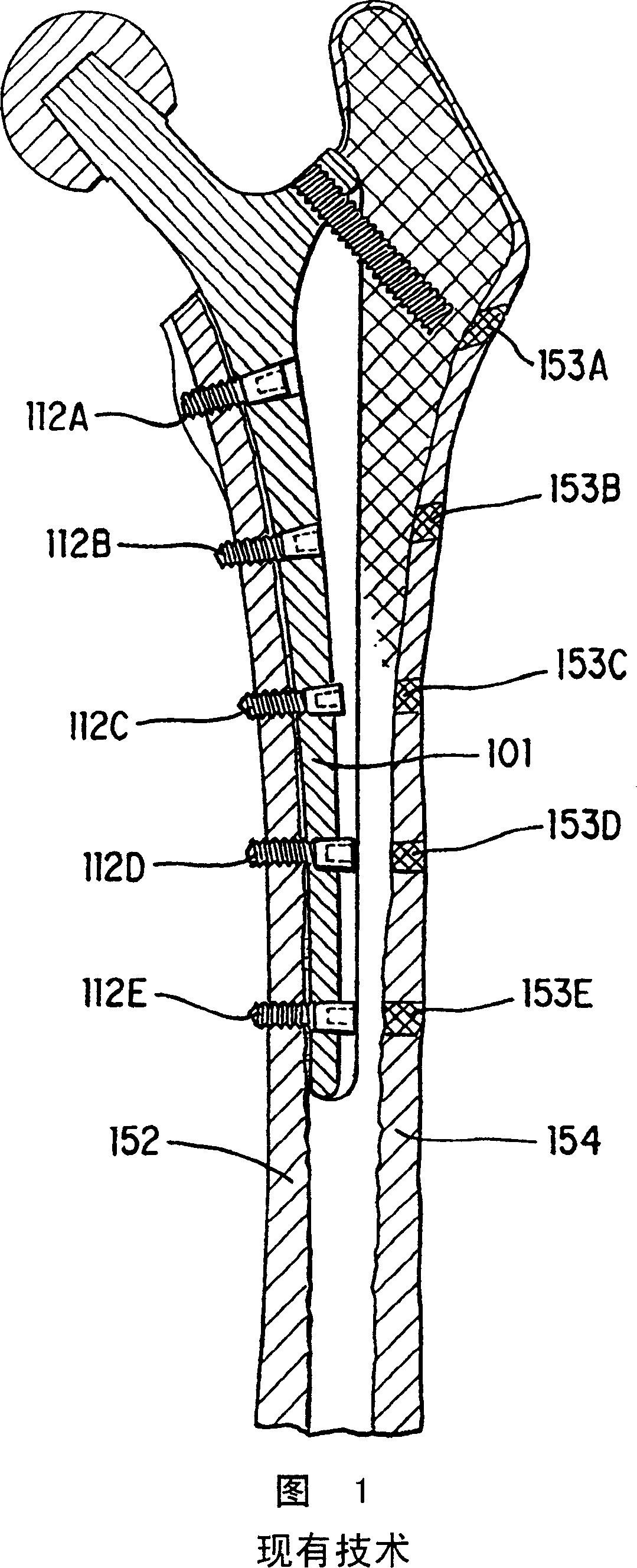

[0040] current technology

[0041] As discussed in detail above, cemented and uncemented (mortarless) hip prostheses have now become an expanding industry with its identified problems, including loss of bone due to movement of the diaphysis and bone at the interface; soft tissue formed at the interface can develop gross instability; and osteolysis can develop global loosening or even fracture of the prosthetic components. While the design disclosed in the '654 patent addresses many of these problems, there is still much room for improvement from a surgical standpoint.

[0042] Cementless, screwed femoral components are known in the art, such a component as disclosed in the '654 patent is shown in FIG. 1 . Screws 112A through 112E attach the femoral components to the mesocortex 152, thus overcoming some of the problems with cemented femoral components. However, this design requires trauma to a part of the patient's body that is not required for long-term immobilization of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com