Double half-carcass tyre with lowered crown reinforcements

A technology for reinforcements and tires, applied to special tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve problems such as limited room for maneuver, achieve the effect of reducing slippage and increasing water storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

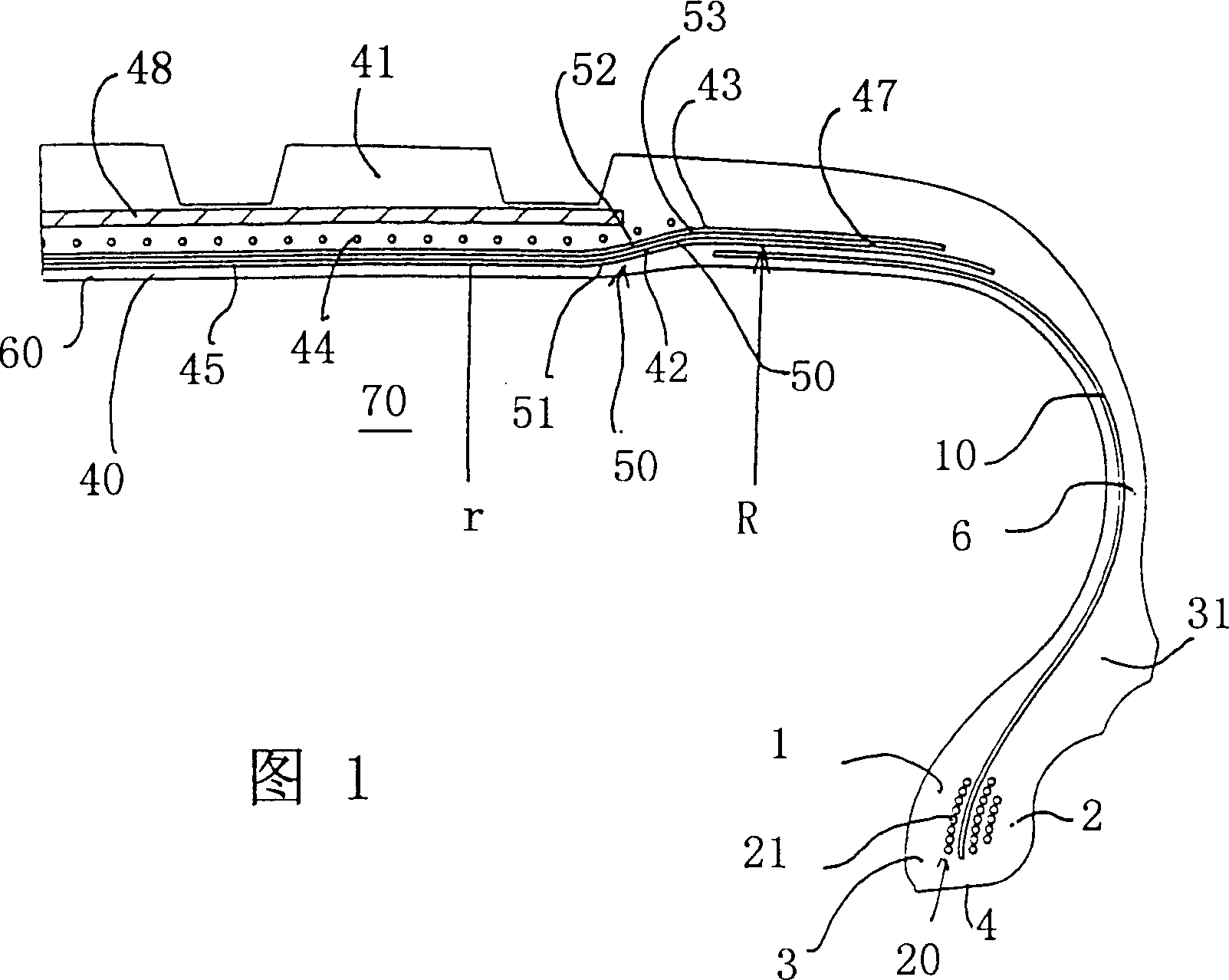

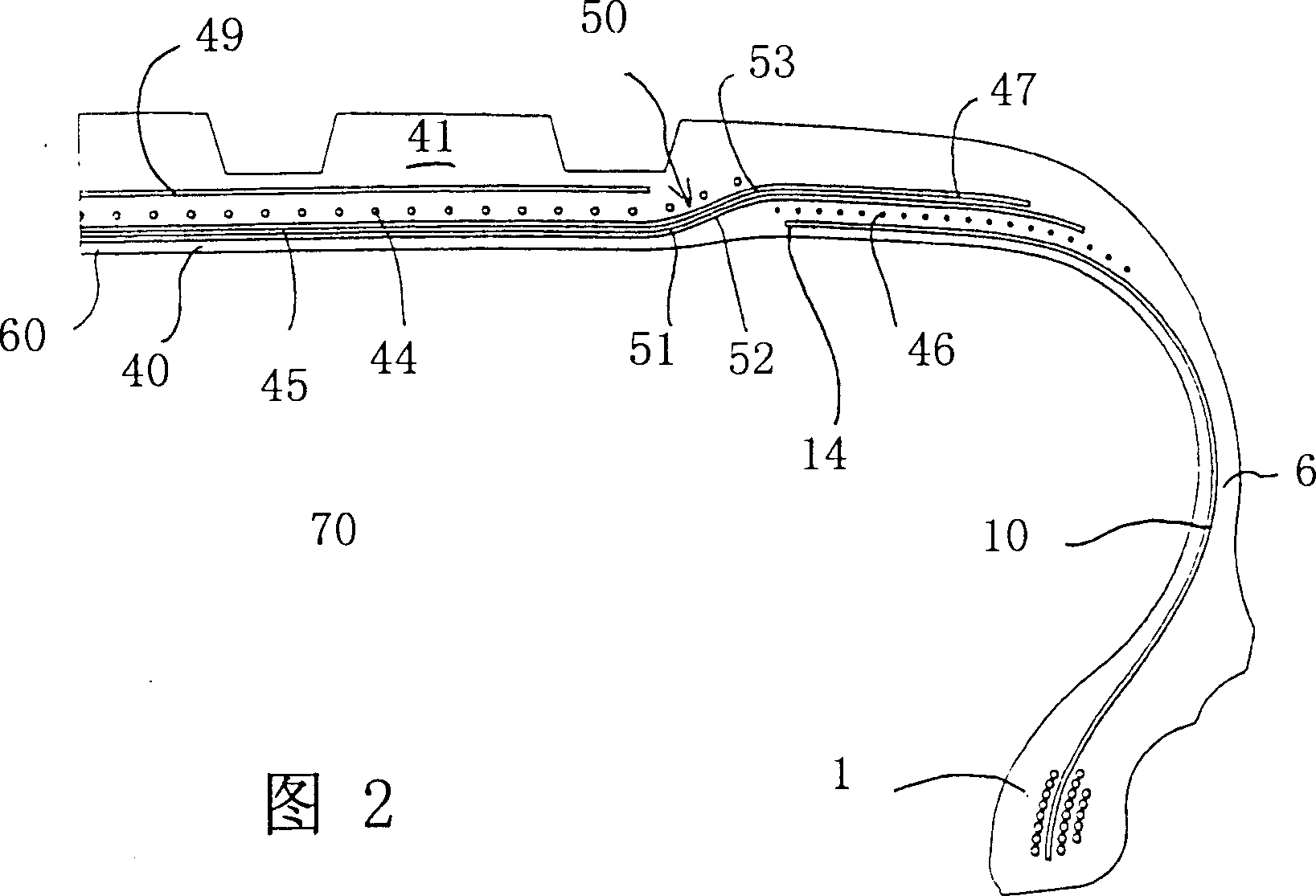

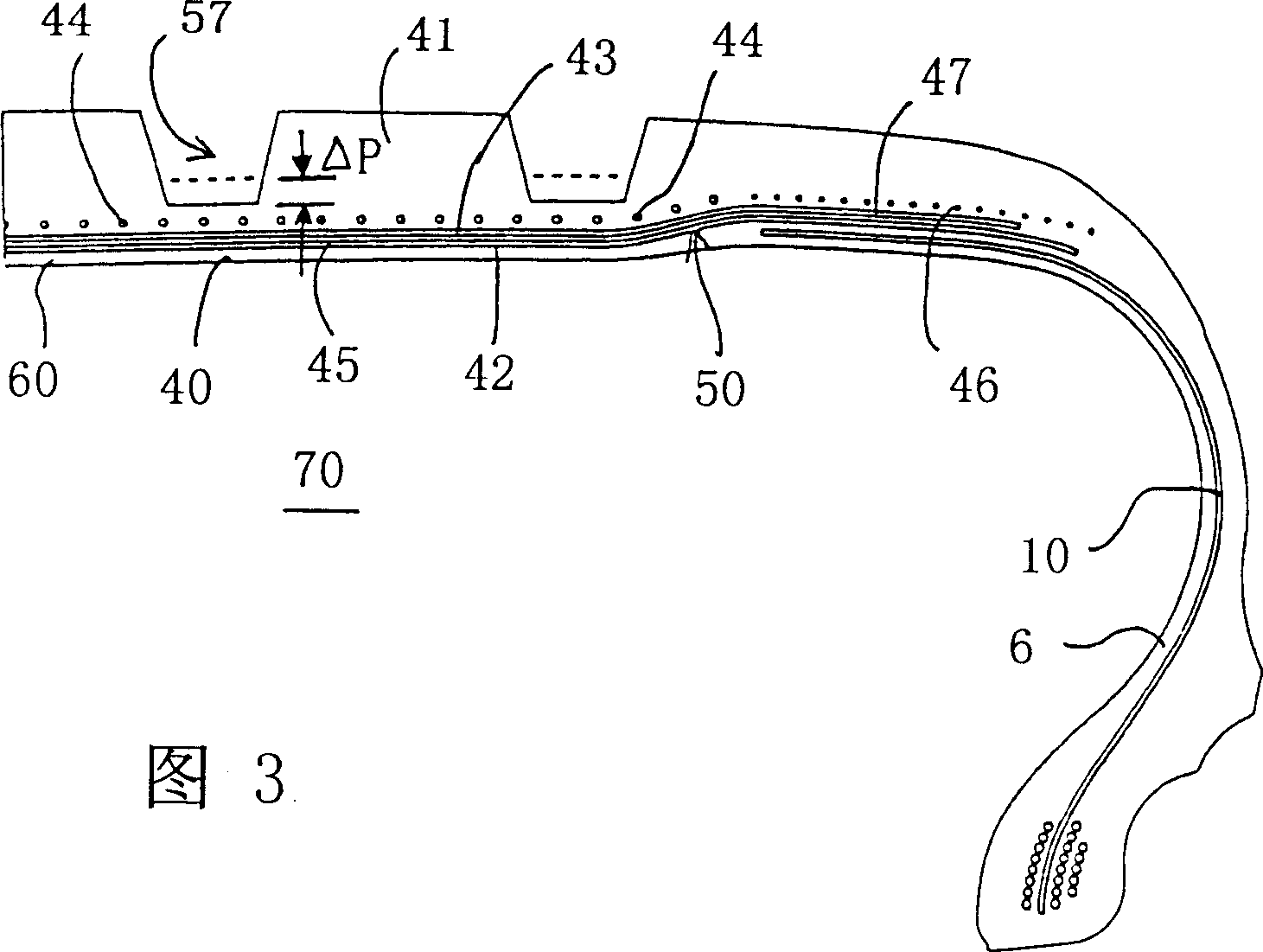

[0051] Figure 1 shows a cross-sectional view of a first form of embodiment of the tire according to the invention. The axially outer portion 2 of the bead 1 is shaped to fit against the flange of the rim. The radially inward end face of the bead 1 is the bead seat 4, which can sit on the rim seat. The bead also comprises an axially inner portion 3 which projects radially from the seat 4 towards the sidewall 6 .

[0052] The tire also comprises a reinforcing structure 10 or carcass-shaped reinforcing structure on which the reinforcements are arranged substantially radially. The structure preferably consists of two parts, for example one on each side of the tire along the sidewalls, but not covering the entire crown.

[0053] The reinforcement included in the crown 40 consists of at least one, preferably two, primary reinforcement structures (crown plies) that provide the required protection and rigidity to this area of the tire. In the example shown in FIG. 1 , the inner m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com