Rotary actuator device for controlling the stroke of a gas-shuttle poppet valve in the cylinder head of an internal combustion engine

A technology for cylinder and stroke control of an internal combustion engine, applied to valve drive devices, non-mechanically actuated valves, valve devices, etc., can solve the problems of unstable control cam position and continuous load on the power grid on the vehicle, avoiding overshoot, structural small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

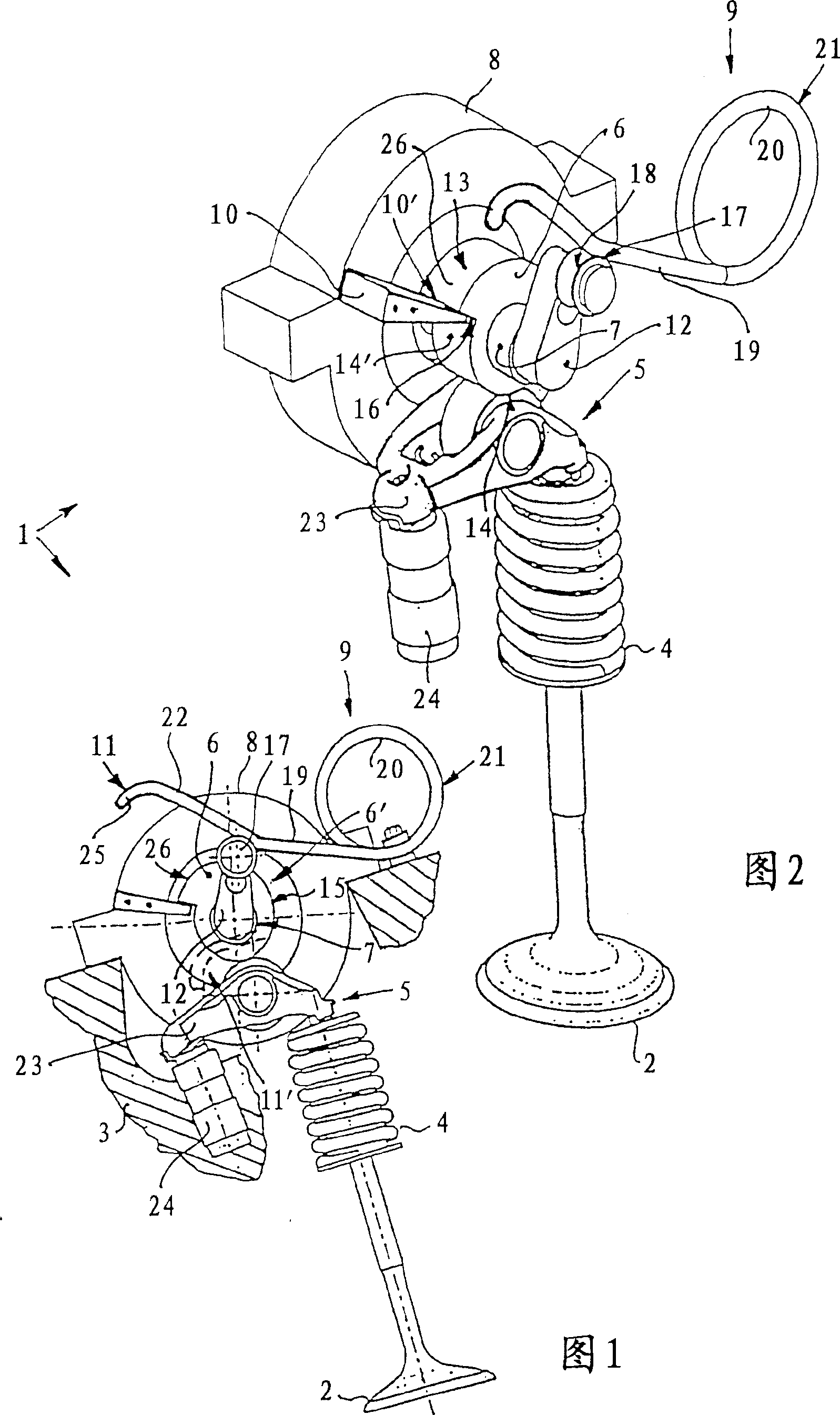

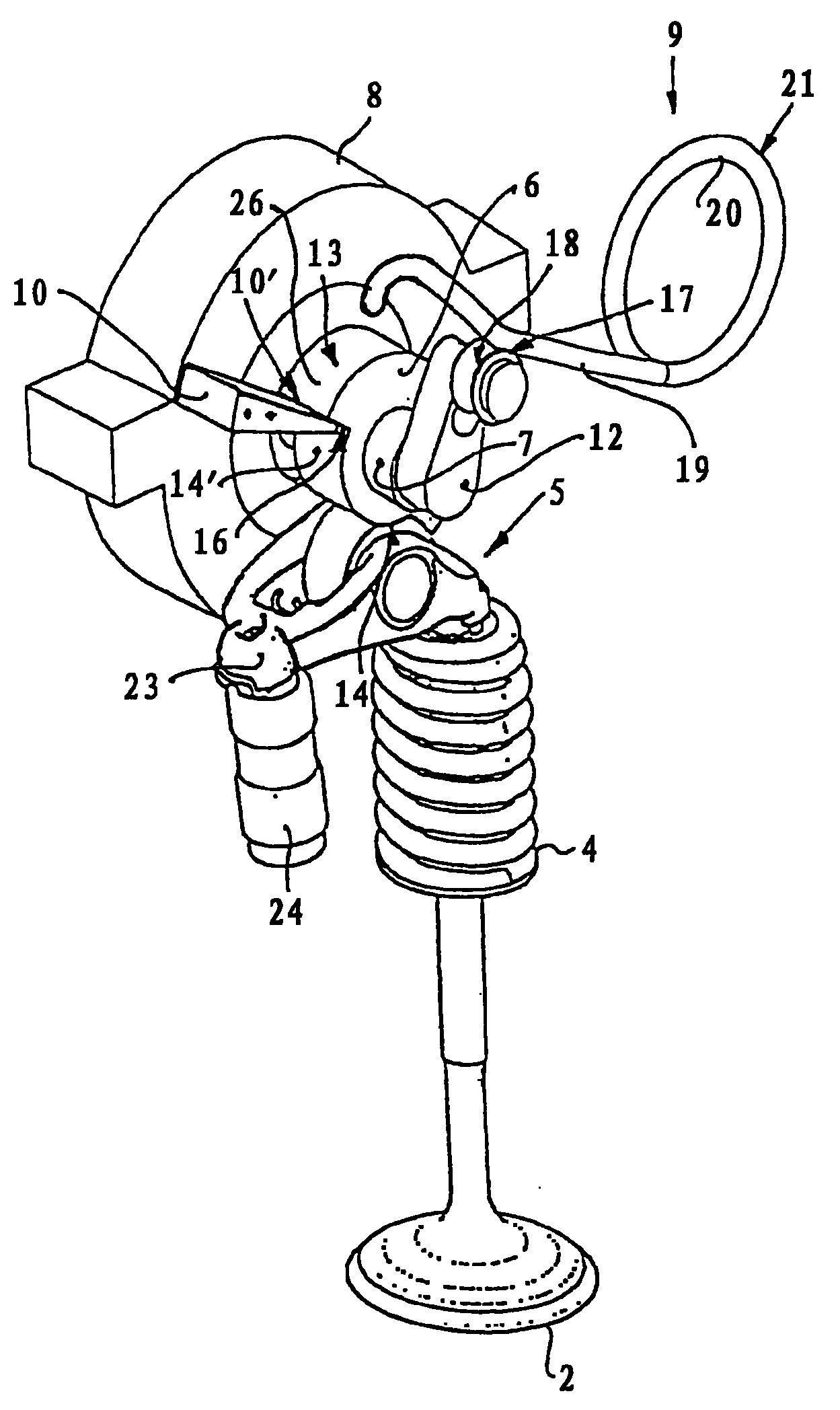

[0026] In a rotary actuator 1 for stroke control of a mushroom valve 2 in a cylinder head 3 not shown in detail of an internal combustion engine not shown in the figure, a mushroom valve 2 loaded by a valve closing spring 4 is In the case of element 5 as an intermediate connection, the travel is controlled by means of a control disk 6 , wherein the control disk 6 , which is rotationally fixed to the shaft 7 , is in drive connection with a universal characteristic curve-controlled, in particular electric, rotary oscillating motor 8 . The rotary pivot motor 8 is controlled in cooperation with a valve closing spring 4 and a prestressed valve opening spring 9 via a control disk 6 acting oppositely to the valve closing spring 4 .

[0027] In order to achieve that the control disk is absolutely held when the internal combustion engine is not in operation, the mushroom valve 2 is in the end position, while the rotary oscillating motor 8 is not powered; Relatively little energy provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com