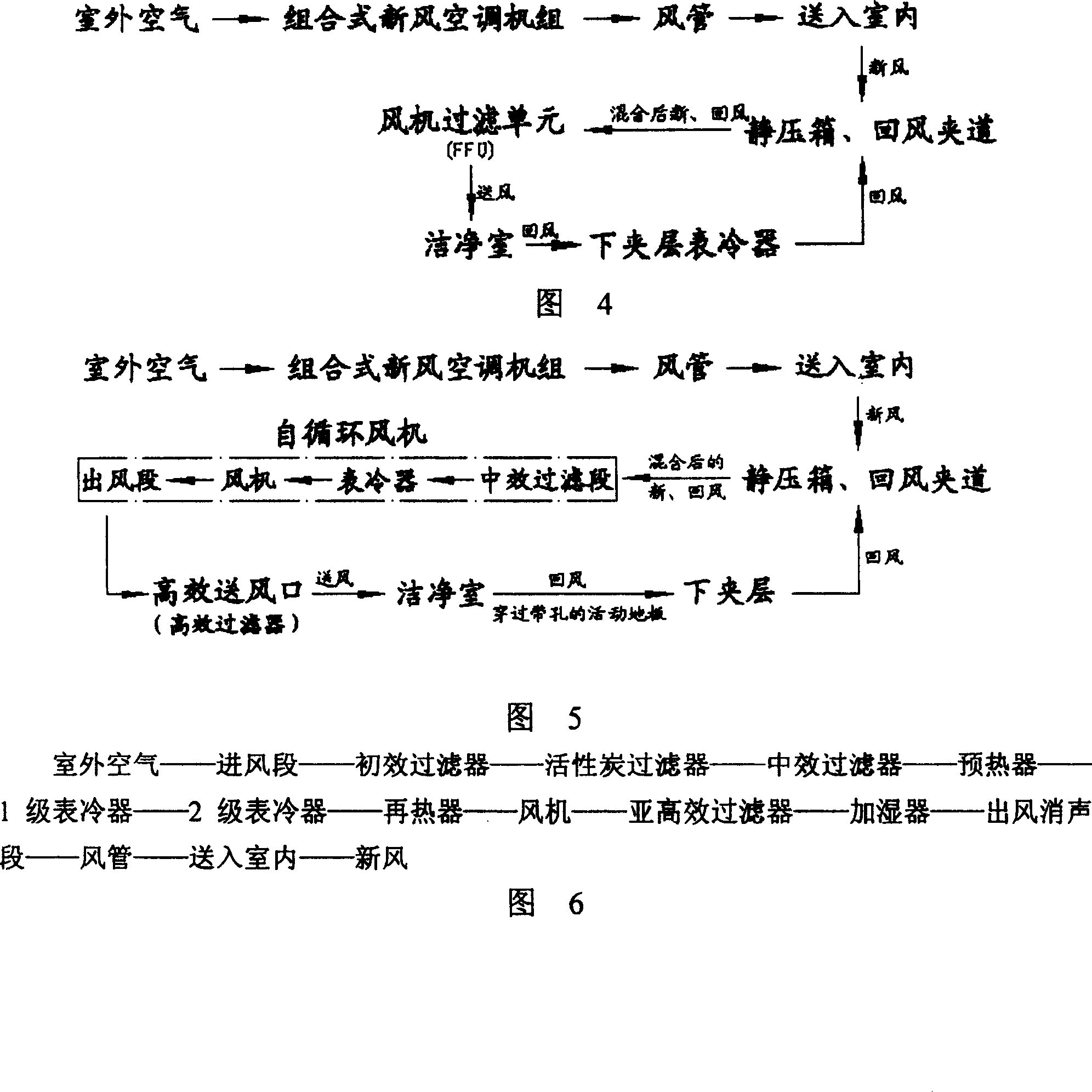

Flow pattern of air conditioning and purifying system in cleaning room

An air conditioning and purification system technology, applied in air conditioning systems, space heating and ventilation, household heating, etc., can solve problems affecting the service life of high-efficiency filters 1, air volume, wind pressure limitations, and small room for adjustment, etc., to achieve The effect of low noise, saving operating cost, and simplifying the sealing form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

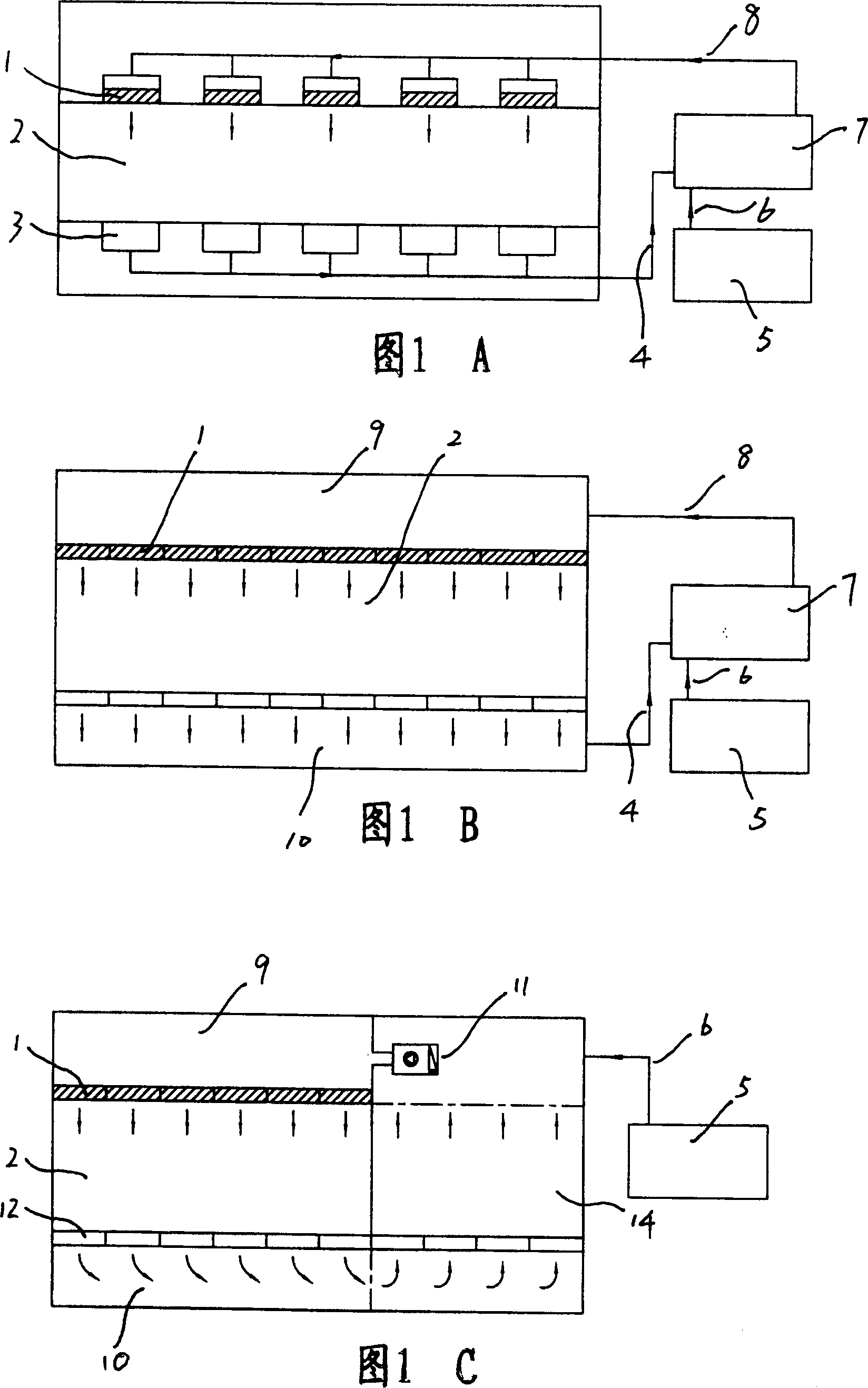

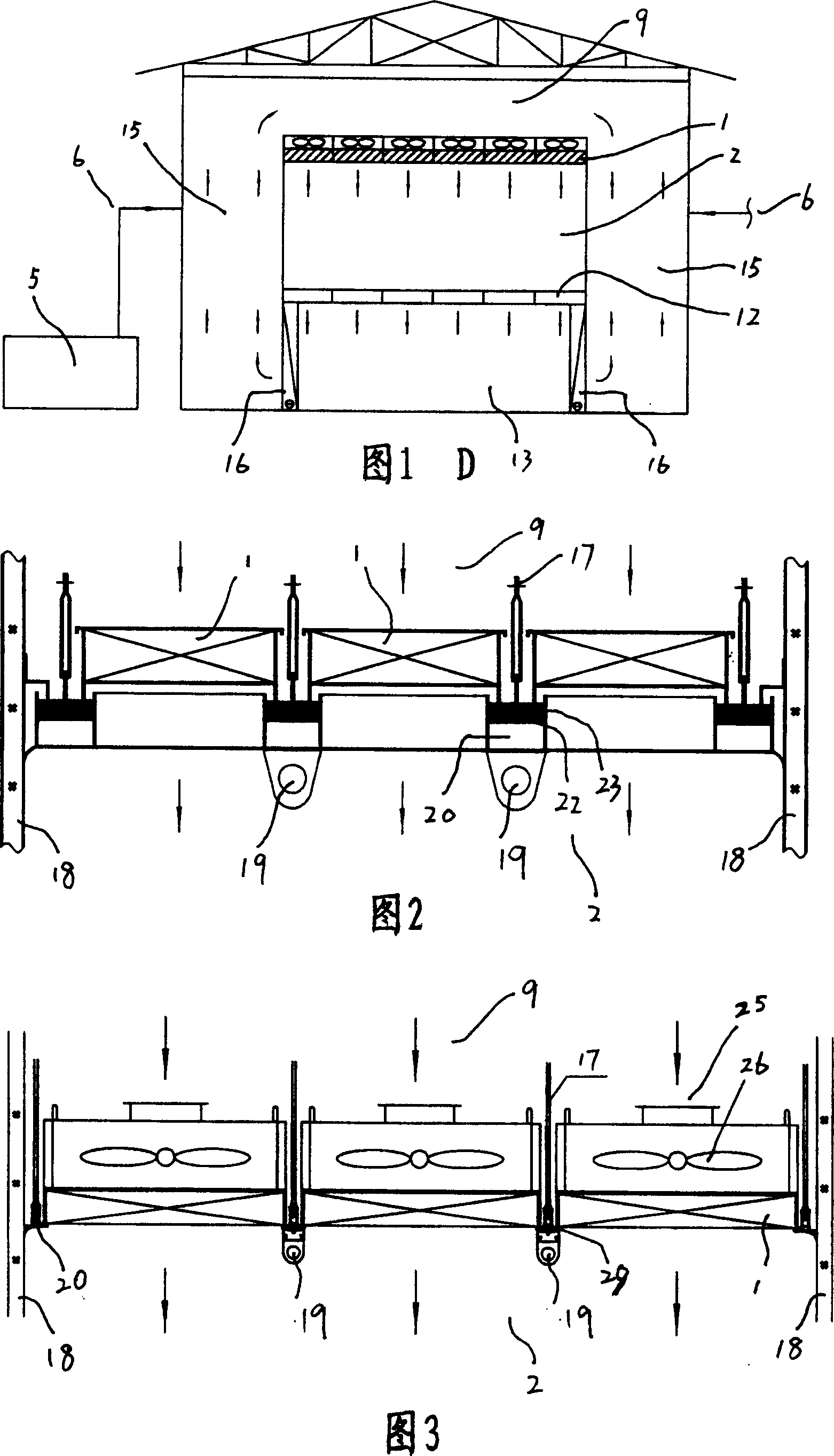

[0034] 1. High-efficiency filter, 2. Clean room, 3. Return air outlet, 4. Return air, 5. Fresh air air conditioning unit, 6. Fresh air, 7. Circulating fan, 8. Air inlet, 9. Static pressure box layer, 10. Lower mezzanine, 11. Self-circulating fan, 12. Raised floor with holes, 14. Equipment area or return air area, 15. Return air duct, 16. Surface cooler, 17. Suspension rod, 18. Wall plate, 19. Clean lighting, 20, keel frame, 22, liquid tank, 23, sealant, 25, tuyere, 26, fan, 27, air duct, 28, shell, 29, sealing gasket.

[0035]As shown in Figure 7: a perforated raised floor 12 is set between the clean room 2 and the lower mezzanine 10 below to separate it. The top of the clean room 2 is a plenum chamber layer 9, and between the clean room 2 and the plenum chamber layer 9 That is, a high-efficiency filter 1 is arranged on the top of the clean room 2 . Both sides of the clean room 2 are return air passages 15, and the fresh air 6 is sent into the return air passage 15 by the fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com