Prepn of common valeriane extractive

A valerian extract and valerian technology are applied in the field of preparation of valerian extract, can solve problems such as long cycle and many procedures, and achieve the effects of stable quality, simple production process and high transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

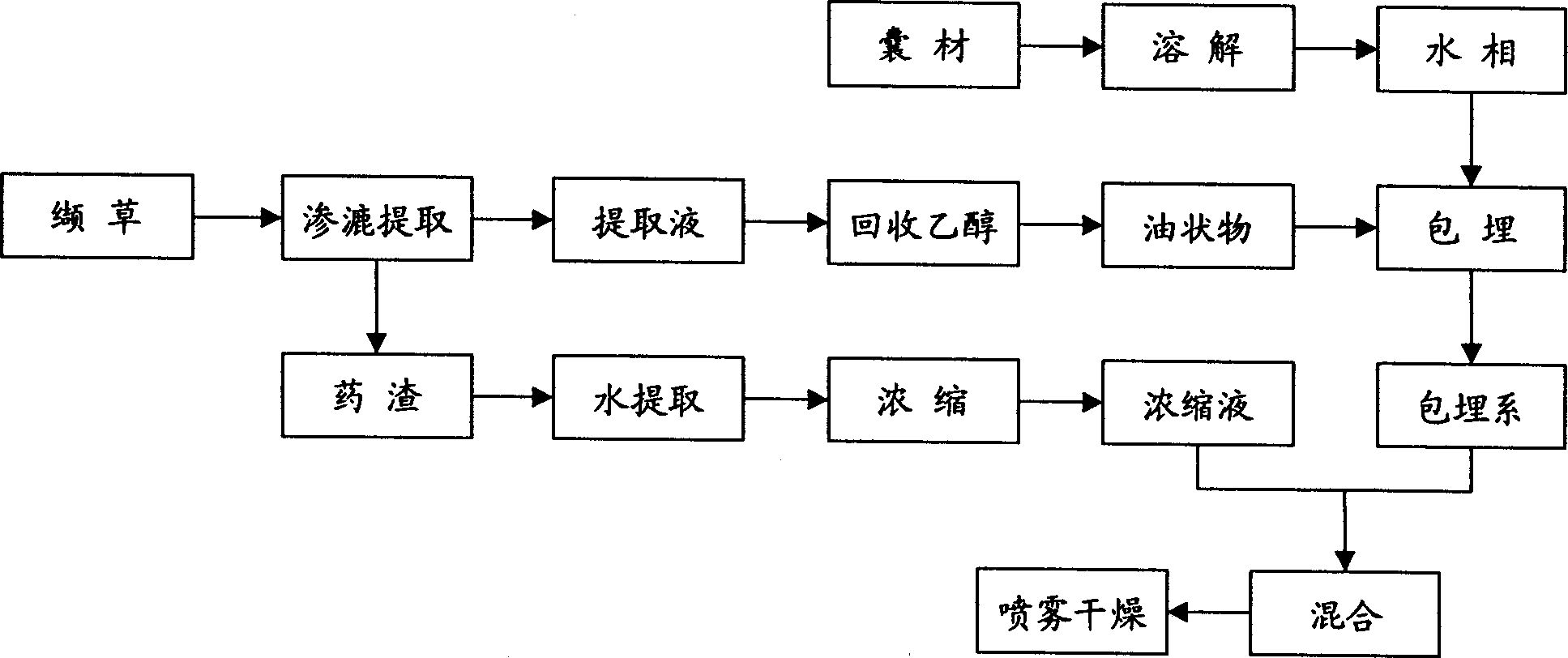

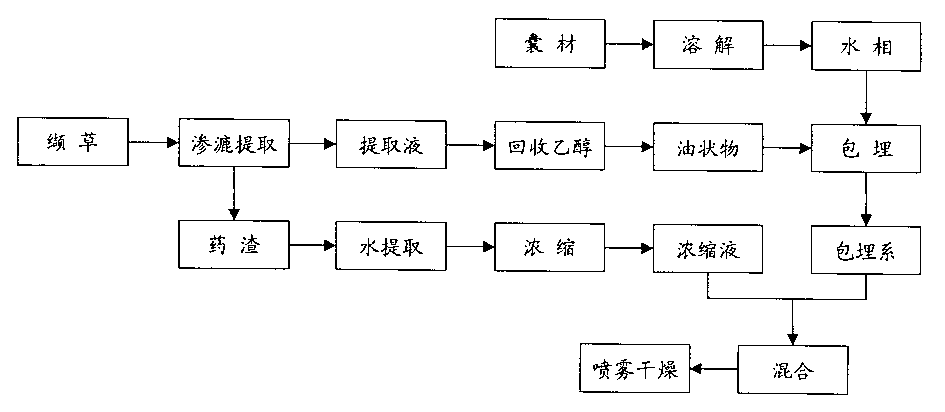

[0011] Such as figure 1 As shown, firstly, 300 kg of Xiecao was taken, soaked with 2 times the amount of 95% ethanol, then placed in a multi-functional traditional Chinese medicine extraction tank, extracted by percolation with 10 times the amount of 95% ethanol, collected the percolation liquid, and reduced it at 45°C. Recover ethanol under pressure to obtain about 16 kg of oil, add 5 times the amount of water to the dregs, heat to boiling, extract for 3 hours, collect the water extract, concentrate under reduced pressure to 9-10 Baume, and obtain a water-extraction concentrate. Take about 30kg of water-soluble capsule material (such as a kind of denatured cornstarch), put it in a mixing tank, add 300kg of water to heat and stir to dissolve, cool to room temperature, add all the above-mentioned oily substances, stir well, then add water to extract the concentrate, stir to mix Uniform, spray-dried to obtain about 58kg of valerian extract. After measurement, the transfer rate ...

Embodiment 2

[0013] Such as figure 1 As shown, first take 300kg of valerian root, soak it with 2 times the amount of 95% ethanol, then place it in a multifunctional traditional Chinese medicine extraction tank, use 13 times the amount of 95% ethanol for percolation extraction, collect the percolation liquid, and depressurize at 40°C Recover ethanol to obtain about 18 kg of oil; add 3 times the amount of water to the dregs, heat to boil, extract for 1 hour, collect the water extract, concentrate under reduced pressure to 5-6 Baume, and obtain a water-extraction concentrate. Take about 19KG of water-soluble capsule material (such as a kind of denatured cornstarch), put it in a stirring tank, add 150kg of water to heat and stir to dissolve, and cool to room temperature; Uniform, spray-dried to obtain about 61kg of valerian extract. After measurement, the transfer rate of volatile oil reaches 69.0%, the transfer rate of valerian triesters is more than 72.0%, and the encapsulation and embeddin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com