Electrode type digital liquid level controlling device

An electrode-type, digital technology, applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve the problems of poor anti-interference ability of analog signals, large energy consumption of equipment, poor working stability, etc., and achieve structural Compact, reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

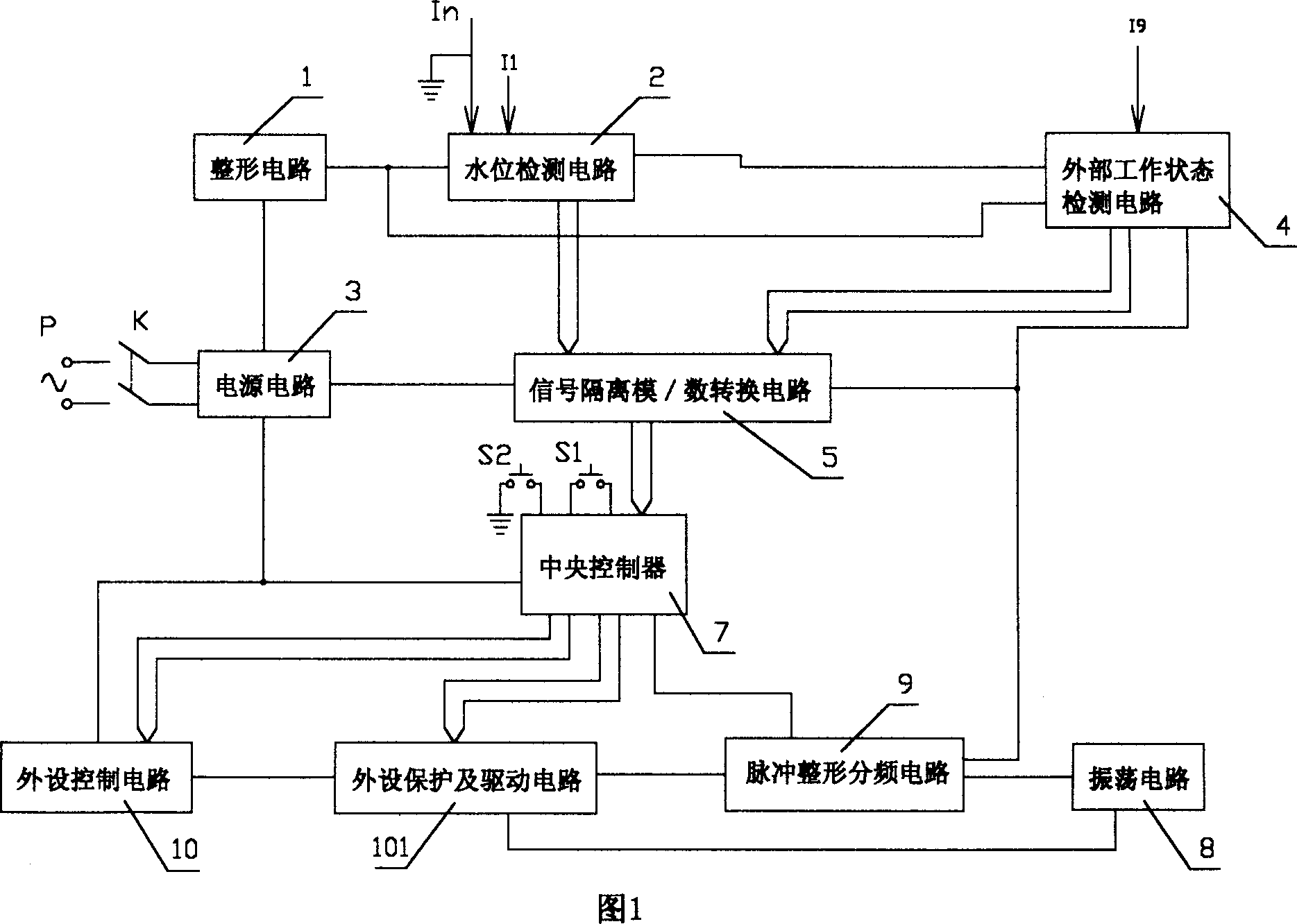

[0021] According to Figure 1 and Figure 4 , the present embodiment includes a power supply circuit 3, the power supply circuit 3 is connected with the shaping circuit 1, the signal isolation analog / digital conversion circuit 5, the central controller 7 and the peripheral control circuit 10, and provides corresponding working power; the shaping circuit 1 is connected with a The external working state detection circuit 4 is connected to a water level detection circuit 2, and the water level detection circuit 2 is connected to a grounded water level sensing line In and another water level sensing line I1, and the grounded water level sensing line In and the water level sensing line I1 is respectively connected with sensor probe electrodes 301, the water level detection circuit 2 receives the sensing current from between the sensor probe electrodes 301, and the external working state detection circuit 4 receives the working state signal I9 of the water pump 70, and is isolated fro...

Embodiment 2

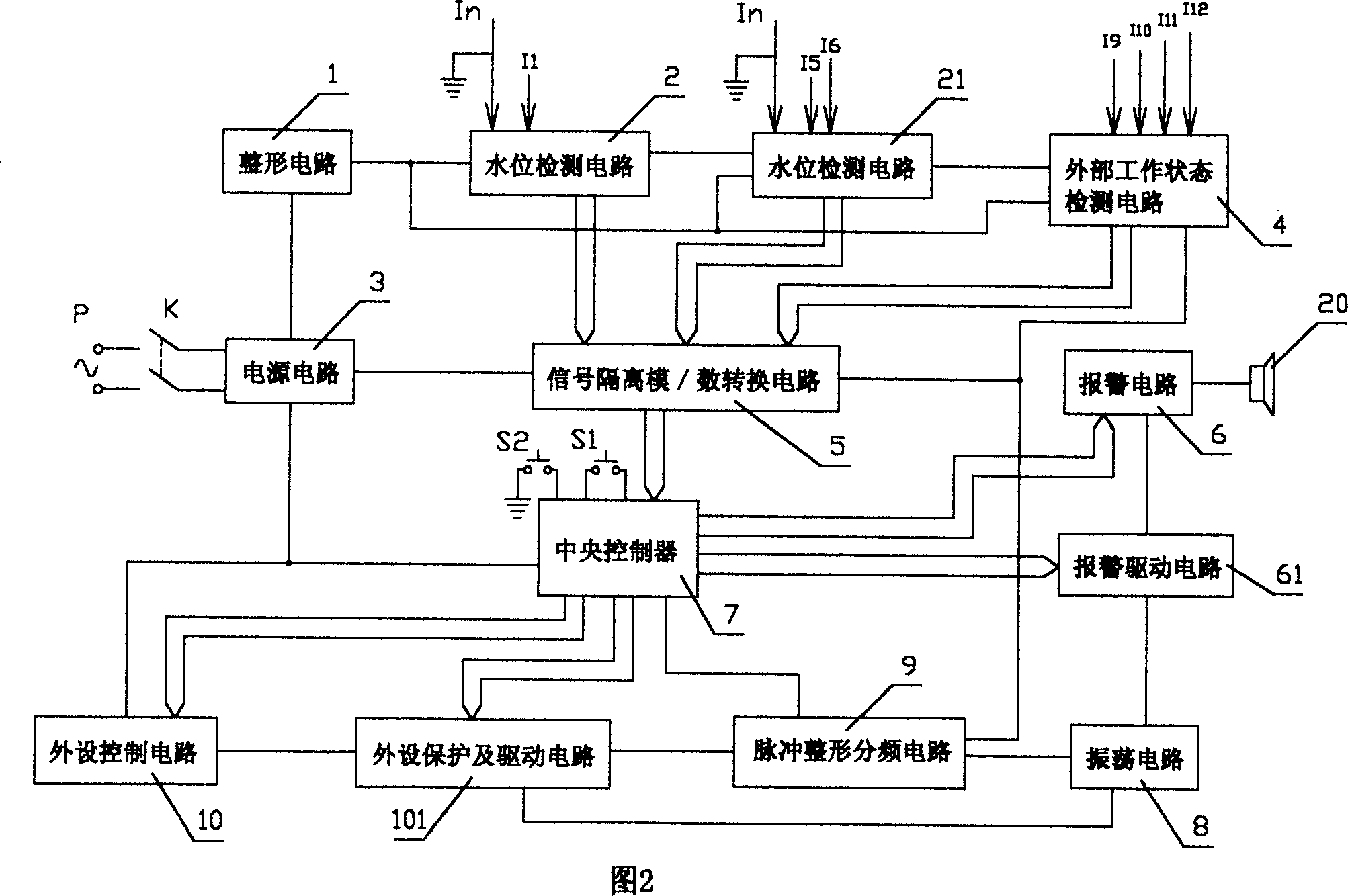

[0029] According to Figure 2 and Figure 5The difference between this embodiment and the previous embodiment is that the shaping circuit 1 is connected with another water level detection circuit 21, and the water level detection circuit 21 is connected with a grounded water level sensing line In and two water level sensing lines I5, I6, The grounded water level sensing line In and the water level sensing lines I5 and I6 are respectively connected with sensor probe electrodes 301 placed in the reservoir 80, and the sensor probe electrodes 301 connected to the grounded water level sensing line In are placed oppositely. At the lowest point, the sensor probe electrode 301 connected to the water level sensing line I6 is placed at the relatively highest point, and the water pump 70 draws water from the reservoir 80; the external working state detection circuit 4 receives the working state signal I9 of the water pump 70, that is, the water pump 70 Open and close state, also receive w...

Embodiment 3

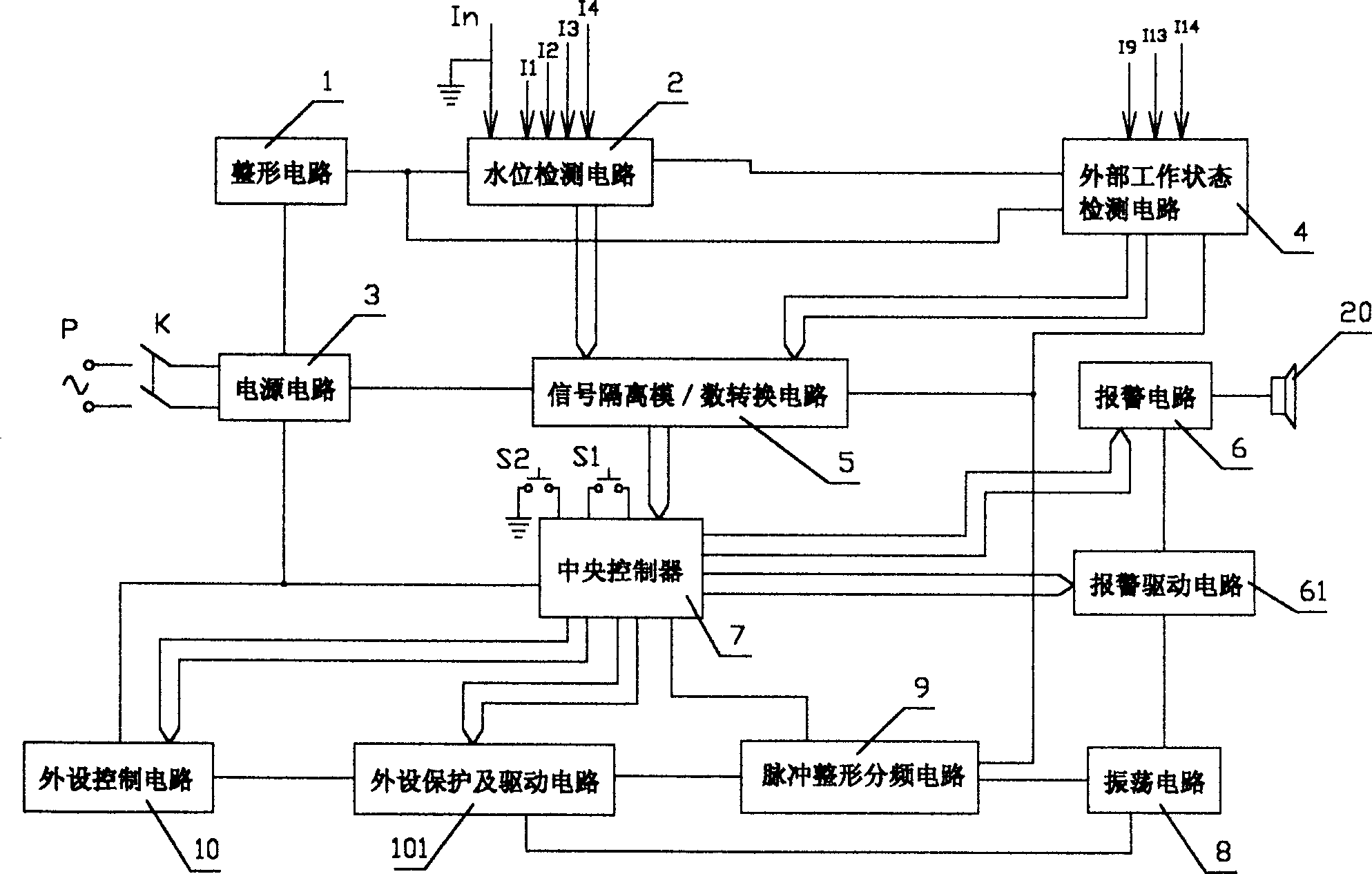

[0034] according to image 3 and Figure 6 , the present embodiment includes a power supply circuit 3, the power supply circuit 3 is connected with the shaping circuit 1, the signal isolation analog / digital conversion circuit 5, the central controller 7 and the peripheral control circuit 10, and provides corresponding working power; the shaping circuit 1 is connected with a The external working state detection circuit 4 is connected to a water level detection circuit 2, the water level detection circuit 2 is connected to a grounded water level sensing line In and four water level sensing lines I1, I2, I3, I4, and the grounded water level sensing line In The sensor probe electrodes 301 are respectively connected to the water level sensing lines I1, I2, I3 and I4, the water level detection circuit 2 receives the sensing current from between the sensor probe electrodes 301, and the external working state detection circuit 4 receives the working state of the water pump 70 Signal I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com