Mud level displaying alarm and well mud level monitoring method

A technology of liquid level display and alarm device, which is applied in the direction of buoy liquid level indicator, earthwork drilling, wellbore flushing, etc. It can solve the problems of not being able to deal with well kick and lost circulation in time, unintuitive image, and affecting normal post operations, etc. It is easy to distinguish the phenomenon of well kick and lost circulation, prevent well wall from collapsing and stuck pipe, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

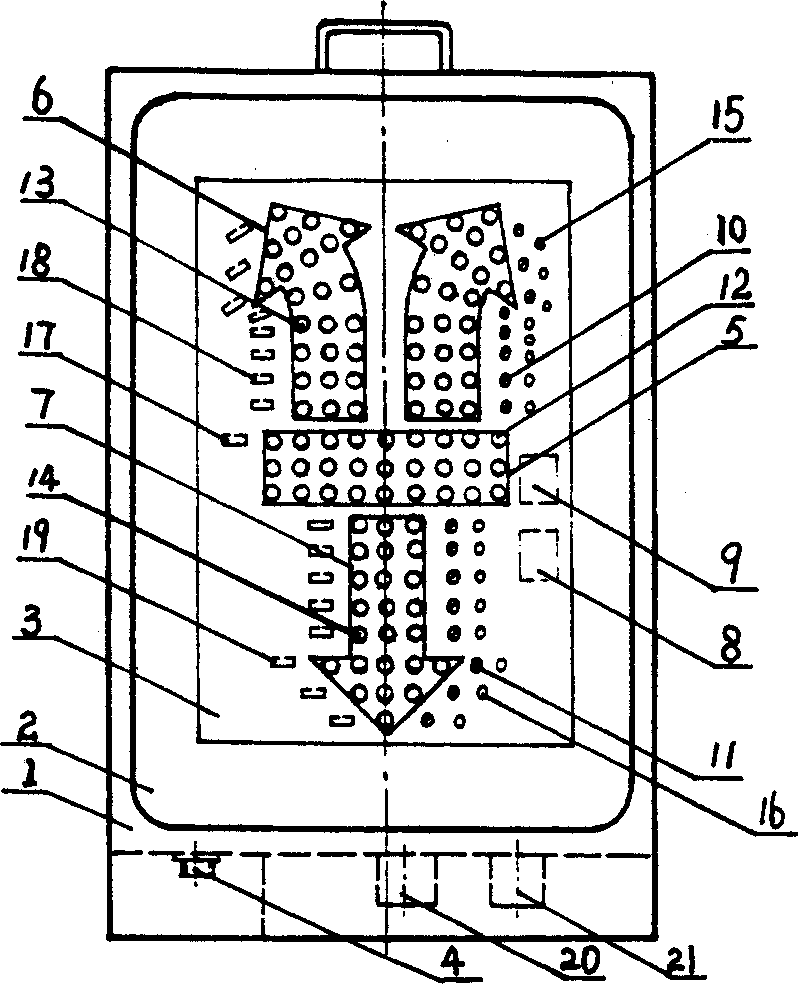

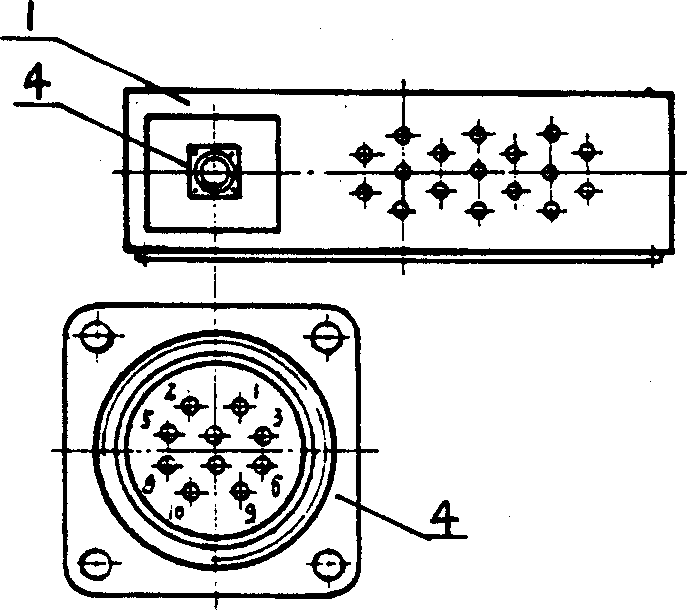

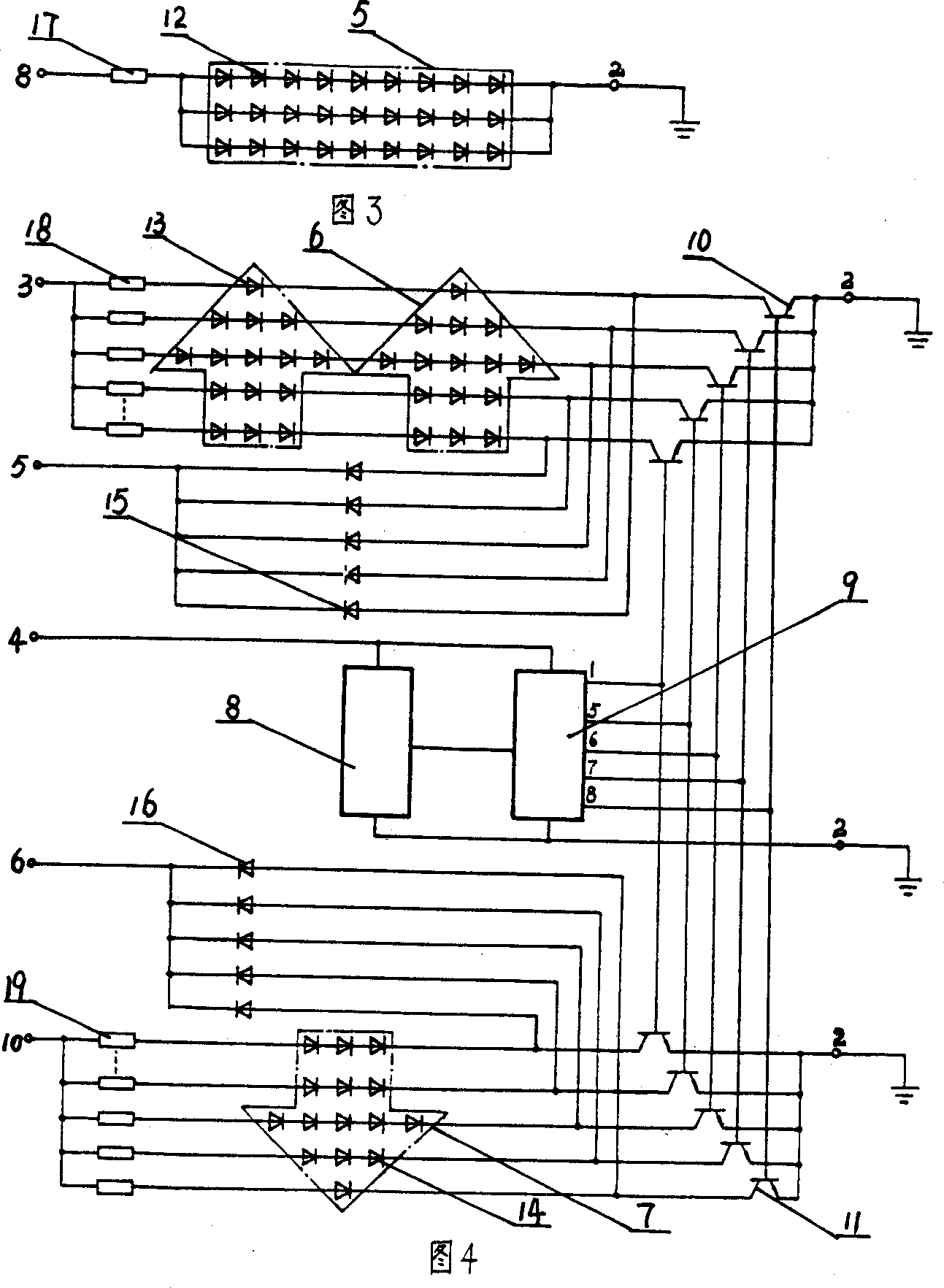

[0036] Example 1. During the drilling process, the mud level of the tank group is automatically displayed and alarmed, and the liquid level of the wellbore 41 is abnormally displayed:

[0037] During the drilling process, the tripping / drilling button switch 42 is thrown at the "drilling" position, the controller 33 is connected to the 220V control power supply, and the power button 43 is pressed, the controller 33 passes the cable 44 and the mud level display alarm device 34 The No. 8 contact of the ten-core socket 4 is connected to the 24V voltage, the green mud level indicator light 5 is on, and the reset button 45 is pressed, and the mud level display alarm device 34 enters the mud tank 22, 23 groups of liquid levels to automatically display the alarm control state. The liquid level height signal detected by the floats 46 of the drilling mud tanks 22 and 23 is converted into the resistance signal of each potentiometer 50 by connecting the belt 47, the pulley 48 and the tran...

Embodiment 2

[0044] Example 2. Automatic display and alarm of the mud level of the tank group and the mud level of the wellbore 41 during the tripping process:

[0045] During the tripping process, the drilling pump 56 stops running, the kelly 61 is removed from the lower end screw and the faucet 60 is placed in the mouse hole, the drilling mud is not circulated, and the mud level display and alarm device is tanked in the same way as in Example 1. Group mud level automatic display alarm. Connect the 380V power supply, turn the tripping / drilling button switch 42 to the "tripping" position, and the mud level display alarm device 34 enters the state of automatic display and alarm control of the mud level of the tank group during the tripping process, and simultaneously enters the The wellbore mud level automatically displays the alarm control status.

[0046] Wellbore 41 mud level data is automatically displayed and printed:

[0047] During the drilling process, the drill pipe 62, the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com